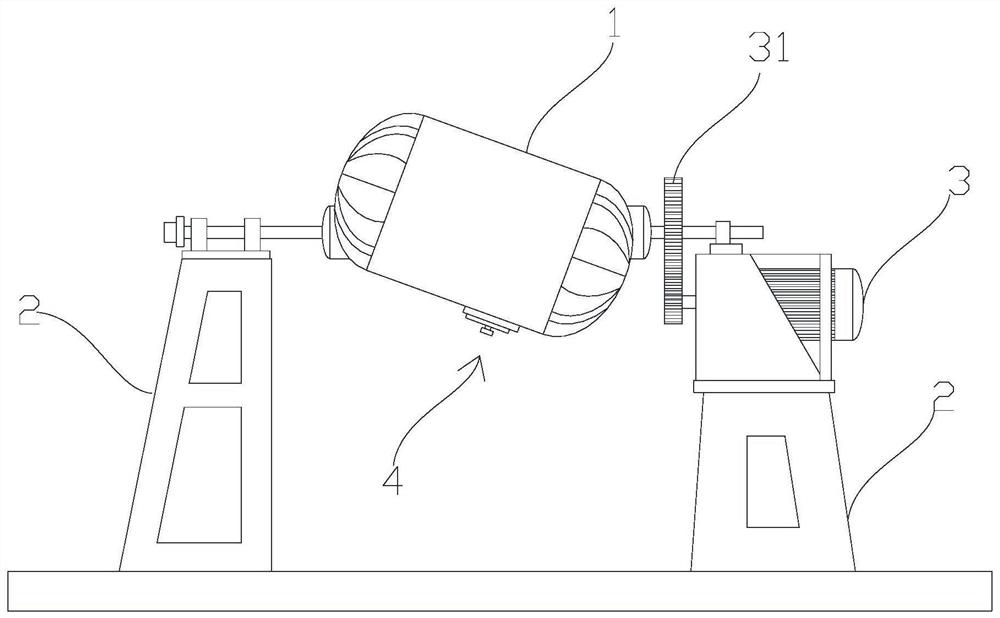

Formation process and vacuum drying equipment for direct powder of Tripterygium hypoglaucum roots

A technology of vacuum drying equipment and molding process, which is applied in the direction of drying solid materials, lighting and heating equipment, and drying solid materials without heating. loss, simplify the production process, and improve the effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

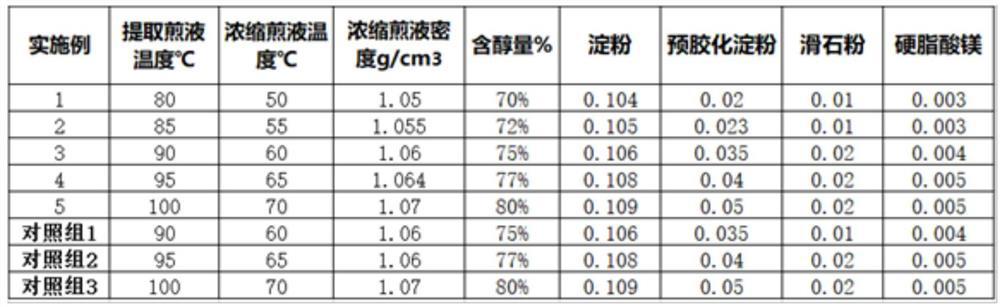

Embodiment 1

[0027] The embodiment of the present invention proposes a molding process of torch flower root straight powder, comprising the following steps:

[0028] (1) Broken: get the torch flower root of 1000g, put it in the crusher, make the torch flower root slice broken into small pieces by changing the frequency of the crusher; The broken way simplifies the process;

[0029] (2) Extraction decoction: Add appropriate amount of water to the broken torch flower root slices. The amount of water added is based on the broken torch flower root slices. Rotate, then perform ultrasonic vibration on it, decoct on high heat for a certain period of time, finally filter to obtain the decoction, repeat the above process several times, and obtain the first decoction; continue to add water to decoct the broken torch flower root slices to obtain the second decoction Decoction for the second time; continue to add water to decoct the broken torch flower root slices to obtain the third decoction;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com