A carbon fiber recycling device and carbon fiber recycling method

A recycling device and recycling method technology, applied in the field of material processing, can solve the problems of less research on carbon fiber metal composite material recycling, large scope, and high manufacturing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

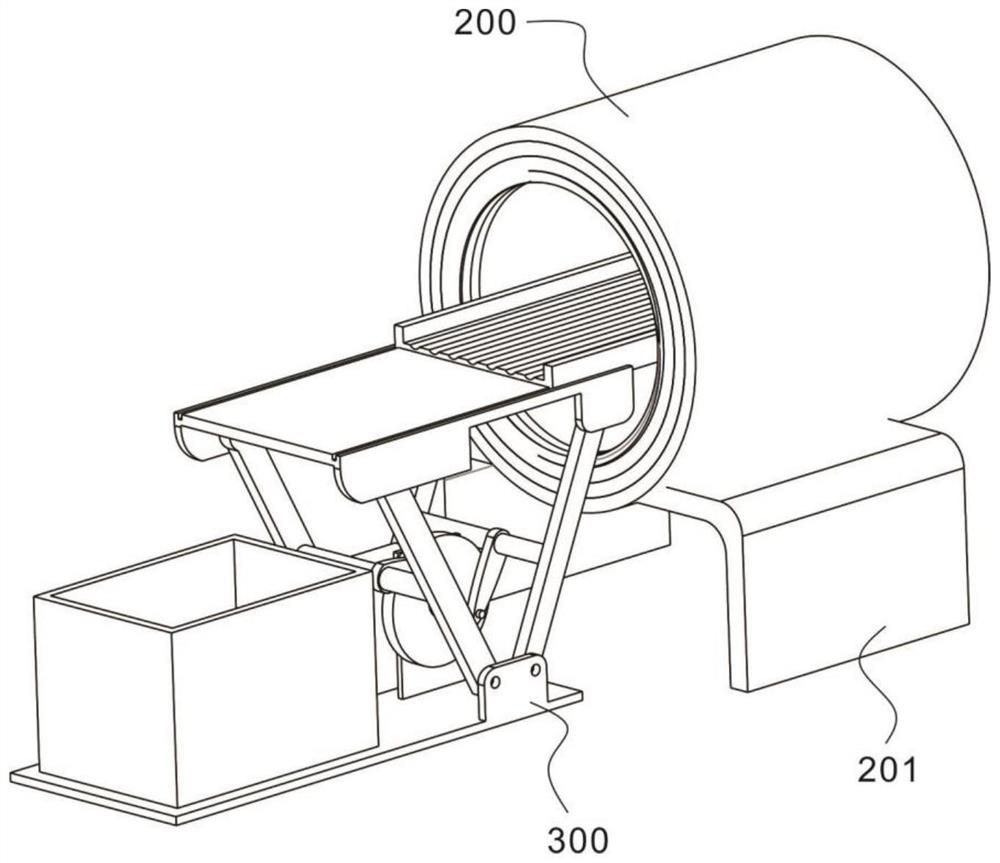

[0034] refer to Figure 1~4 , which is the first embodiment of the present invention, provides a carbon fiber recycling device and a carbon fiber recycling method, the device includes an induction heating assembly 100, a heating cavity 200 and a material dumping assembly 300, wherein the induction heating assembly 100 includes a rectifier 101, A filter 102 connected in series with the rectifier 101, an inverter 103 connected in series with the filter 102, a rectification control circuit 104 connected in parallel with the rectifier 101, and an inverter control circuit 105 connected in parallel with the inverter 103 and power supply 106;

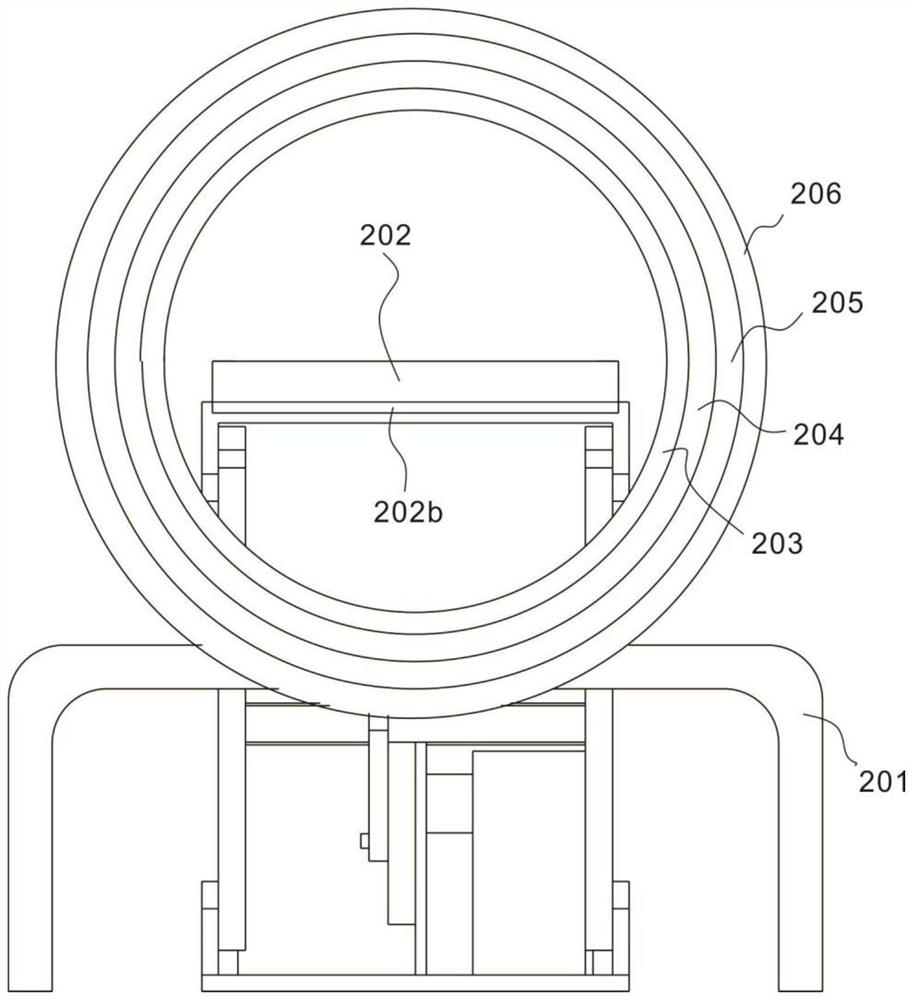

[0035] The heating cavity 200 includes a bracket 201, a processing table 202 fixedly connected to the bracket 201, an induction coil 203, a cylinder 204 sleeved outside the induction coil 203, and a partition sleeved outside the cylinder 204. The thermal cloth 205 and the casing 206 sleeved outside the thermal insulation cloth 205; and,

[0...

Embodiment 2

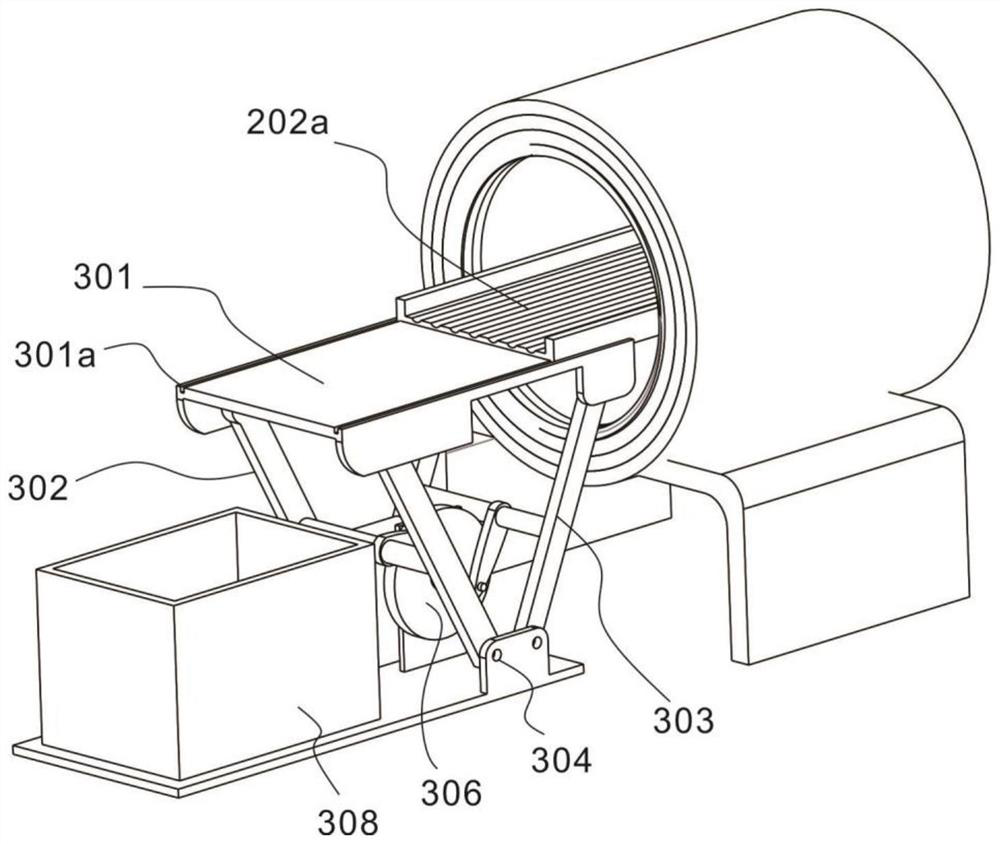

[0041] refer to Figure 1-8 , is the second embodiment of the present invention, which is different from the first embodiment in that: the processing table 202 is made of ceramics, and the surface is also provided with a groove 202a parallel to the longitudinal direction of the heating chamber 200, and A limiting plate 202b is provided at its end.

[0042] Compared with Embodiment 1, further, the outer surface of the entire heating chamber 200 is a layer of metal round wall shell 206, and the metal round wall shell 206 is welded on the bracket 201 by welding, and the function of the metal round wall is mainly The structure inside the heating chamber 200 is protected to prevent collisions during transportation, installation and use.

[0043] Inside the shell 206 is a layer of thermal insulation cloth 205 made of ceramic fiber cloth, which can play a role in heat preservation and heat insulation, and reduce the loss of energy. At the same time, the ceramic fiber cloth can bette...

Embodiment 3

[0050] refer to Figure 1-8 , is the third embodiment of the present invention, and this embodiment is different from the second embodiment in that: the surface of the mobile table 301 is provided with a sliding groove 301a cooperating with the processing table 202, the bottom is provided with a guide groove 301b, and the first One end of the connecting rod 302 connected to the guide groove 301b is provided with a guide wheel 302a, and the guide wheel 302a slides in cooperation with the guide groove 301b, and one end of the second connecting rod 303 connected to the mobile platform 301 is hinged.

[0051] A rotating shaft 303 a is connected between the first connecting rod 302 and the second connecting rod 303 , the rotating shaft 303 a is hinged to the connecting shaft 307 , and the other end of the connecting shaft 307 is hinged to the turntable 306 . The output shaft of the motor 305 is connected with the center of the turntable 306 .

[0052] Compared with Embodiment 2, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com