An adjustable glue filling pump

An adjustable and filling pump technology, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items, can solve the problems of high cost, inaccurate filling volume, troublesome maintenance, etc., to reduce filling errors, speed up filling, The effect of increasing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

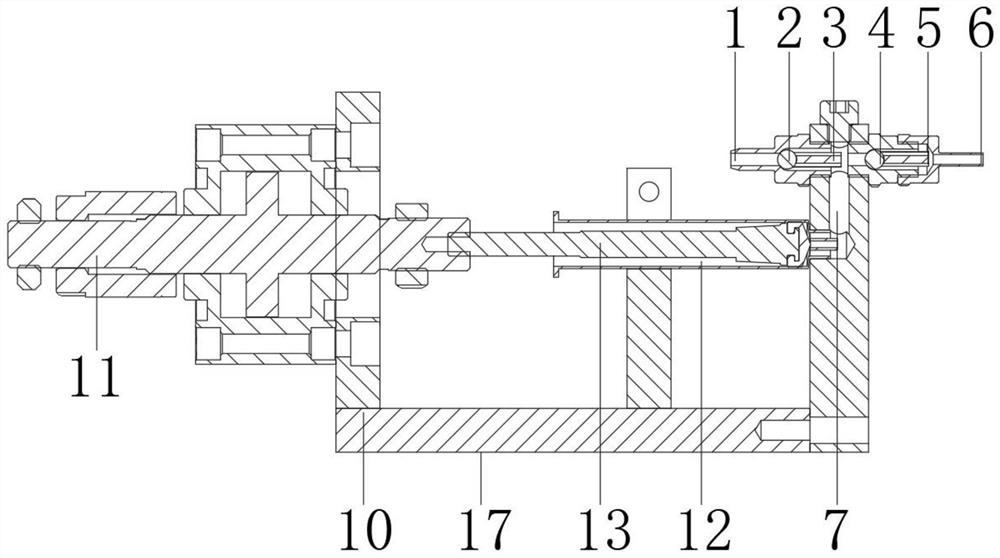

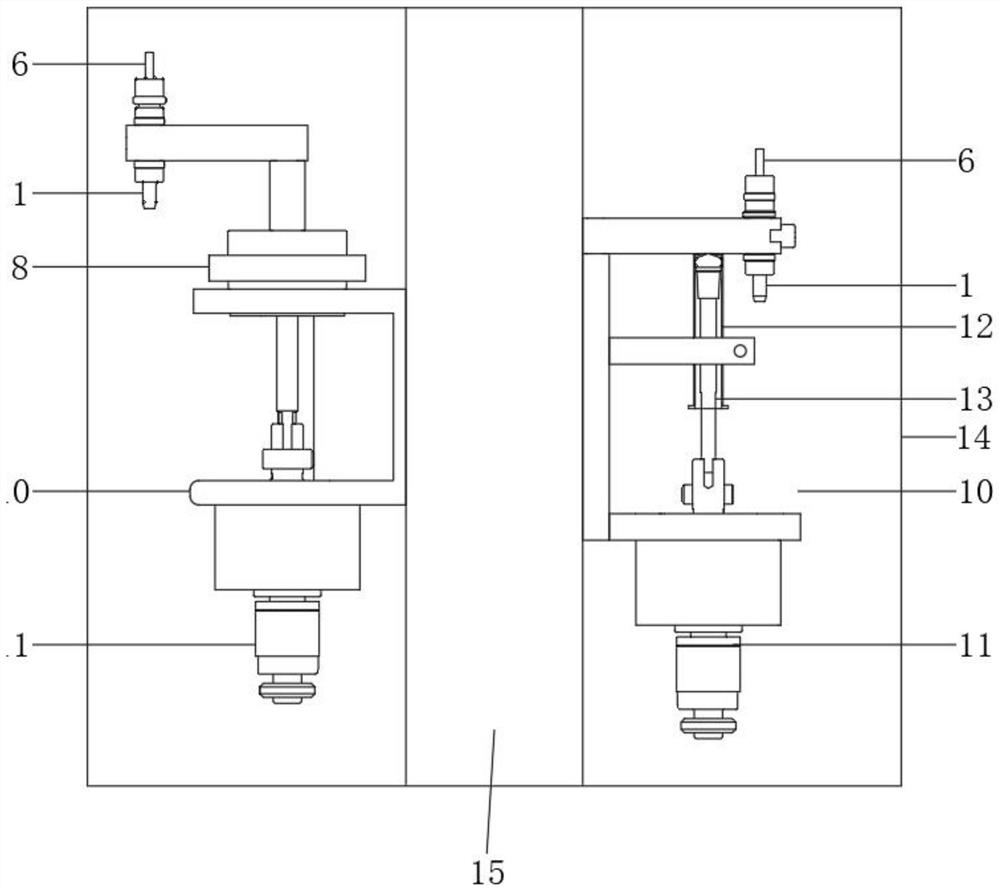

[0021] see figure 1 and image 3 , an embodiment provided by the present invention:

[0022] An adjustable glue filling pump, including a glue inlet 1, a first sealing steel ball 2, a first steel ball top block 3, a second sealing steel ball 4, a second steel ball top block 5, a glue outlet 6, a glue channel 7, and a vacuum chamber 8. Isolation diaphragm 9, mounting bracket 10, adjustable cylinder 11, corrosion-resistant needle tube 12, sealing piston rod 13, bottom plate 14, partition 15, first glue filling mechanism 16 and second glue filling mechanism 17, bottom plate 14 A partition 15 is provided on the upper surface, and a first glue filling mechanism 16 and a second glue filling mechanism 17 are respectively fixed on the two sides of the partition 15 .

[0023] The glue channel 7 of the second glue filling mechanism 17 is connected with the corrosion-resistant needle tube 12. When the user uses it, the user connects the glue inlet 1 and the glue outlet 6 with the glue ...

Embodiment 2

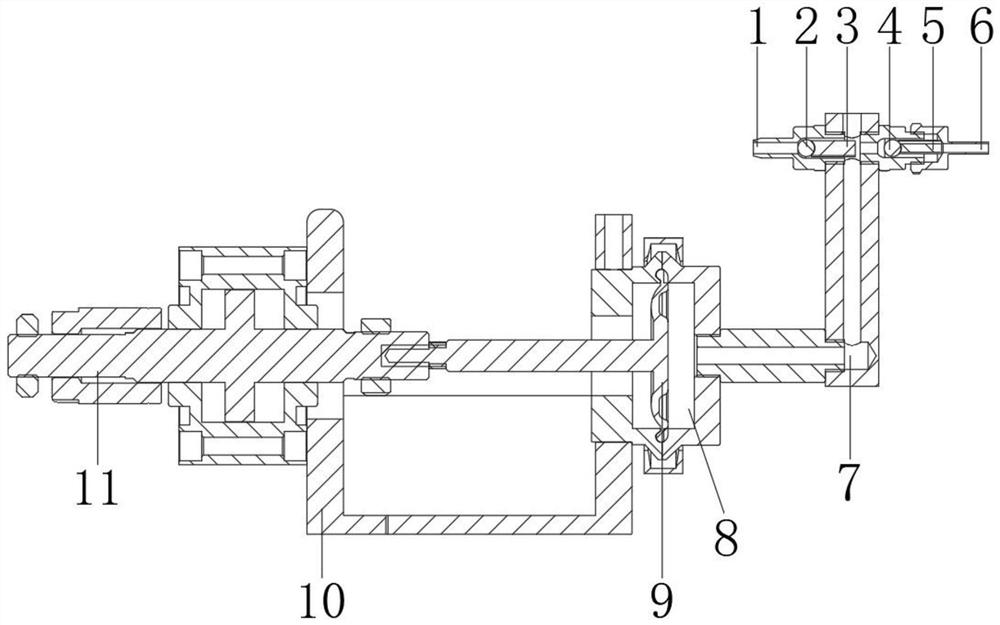

[0027] see figure 2 and image 3 , an embodiment provided by the present invention:

[0028]An adjustable glue filling pump, including a glue inlet 1, a first sealing steel ball 2, a first steel ball top block 3, a second sealing steel ball 4, a second steel ball top block 5, a glue outlet 6, a glue channel 7, and a vacuum chamber 8. Isolation diaphragm 9, mounting bracket 10, adjustable cylinder 11, corrosion-resistant needle tube 12, sealing piston rod 13, bottom plate 14, partition 15, first glue filling mechanism 16 and second glue filling mechanism 17, bottom plate 14 A partition 15 is provided on the upper surface, and a first glue filling mechanism 16 and a second glue filling mechanism 17 are respectively fixed on the two sides of the partition 15 .

[0029] The glue channel 7 of the second glue pouring mechanism 17 communicates with the corrosion-resistant needle tube 12, and an adjustable cylinder 11 is installed on one end of the corrosion-resistant needle tube 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com