Reversible thermochromic shape-stabilized phase change functional material and preparation method thereof

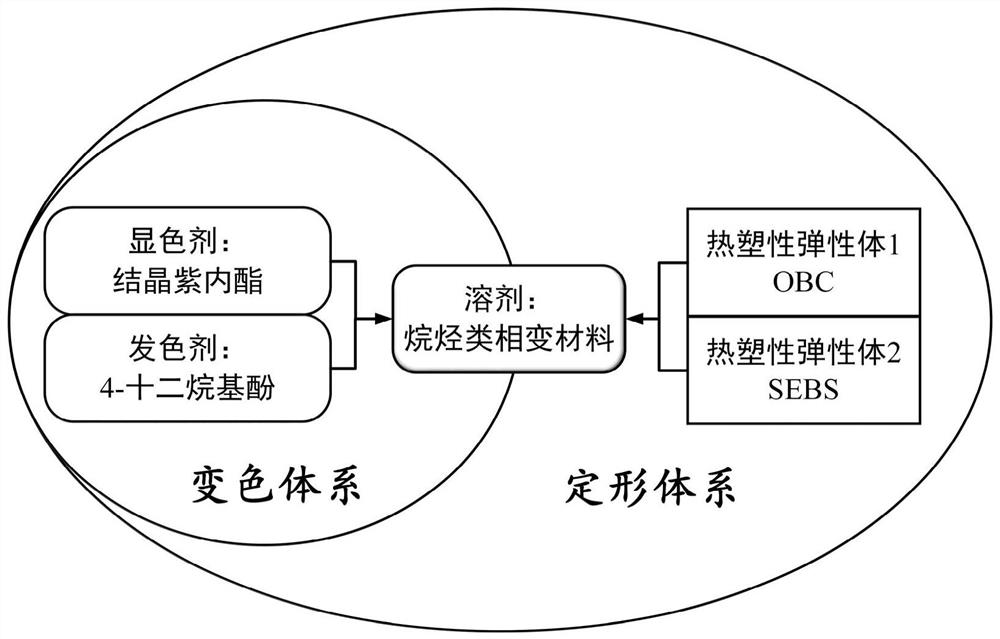

A technology of shape-setting phase change and functional materials, applied in the direction of color-changing fluorescent materials, heat exchange materials, chemical instruments and methods, etc., can solve the problems of no color memory function, poor reversible color stability, and poor shape-setting packaging effect , to achieve the effects of strong reversible color stability, good setting effect and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A reversible thermochromic shape-setting phase-change functional material, including the following raw materials: n-eicosane 55g, KRATON G&EFG1901 3g, INFUSE TM OBC 9530 12g, crystal violet lactone 0.3g and 4-dodecylphenol 0.9g.

[0036] The preparation method of the above-mentioned reversible thermochromic shape-setting phase-change functional material comprises the following steps:

[0037] (1) Mix n-eicosane and crystal violet lactone and sonicate at 45°C and 300W for 10 minutes, then add 4-dodecylphenol, continue to sonicate for 10 minutes, then add KRATON G&E FG1901, and sonicate for 15 minutes , to get a mixture;

[0038] (2) Transfer the mixture obtained in step (1) to an oil bath heating device, mechanically stir and melt blend at 160°C and 60rpm for 30min, and then add dry INFUSE TM OBC 9530, under the conditions of 180°C and 60rpm, mechanically stirred and melt-blended for 30 minutes, followed by casting and cooling to obtain a reversible thermochromic sha...

Embodiment 2

[0042] A reversible thermochromic shape-setting phase-change functional material, including the following raw materials: n-docosane 55g, KURARAY4033 3g, INFUSE TM 12.5 g of OBC 9530, 0.4 g of crystal violet lactone, and 1.2 g of 4-dodecylphenol.

[0043] The preparation method of the above-mentioned reversible thermochromic shape-setting phase-change functional material comprises the following steps:

[0044] (1) After mixing n-docosane and crystal violet lactone, sonicate at 55°C and 400W for 10 minutes, then add 4-dodecylphenol, continue to sonicate for 10 minutes, then add KURARAY 4033, and sonicate for 15 minutes , to get a mixture;

[0045] (2) Transfer the mixture obtained in step (1) to an oil bath heating device, mechanically stir and melt blend at 160°C and 60rpm for 30min, and then add dry INFUSE TM OBC 9530, under the conditions of 180°C and 60rpm, mechanically stirred and melt-blended for 30 minutes, followed by casting and cooling to obtain a reversible thermo...

Embodiment 3

[0049] A reversible thermochromic shape-fixing phase change functional material, including the following raw materials: OP44E phase change wax 50g, FG19013g, INFUSE TM 12 g of OBC 9530, 0.3 g of crystal violet lactone, and 0.9 g of 4-dodecylphenol.

[0050] The preparation method of the above-mentioned reversible thermochromic shape-setting phase-change functional material comprises the following steps:

[0051] (1) After mixing OP44E phase-change wax and crystal violet lactone, ultrasonically treat it at 55°C and 400W for 10 minutes, then add 4-dodecylphenol, continue ultrasonic treatment for 10 minutes, then add FG1901, and ultrasonically treat it for 15 minutes to obtain mixed solution;

[0052] (2) Transfer the mixture obtained in step (1) to an oil bath heating device, mechanically stir and melt blend at 160°C and 60rpm for 30min, and then add dry INFUSE TM OBC 9530, under the conditions of 180°C and 60rpm, mechanically stirred and melt-blended for 30 minutes, followe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com