A kind of fracturing fluid and preparation method thereof

A fracturing fluid and surfactant technology, applied in the field of fracturing, can solve the problems of complex synthesis process of surfactant, slow polymer dissolution rate, harsh synthesis conditions, etc., and achieve excellent fracturing effect, easy degradation, and reaction process. Simple and easy to operate effect

Active Publication Date: 2022-06-03

PETROCHINA CO LTD

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The synthesis process of the above surfactants is complicated, and the synthesis conditions of some surfactants such as erucamide betaine are relatively harsh

Polymers dissolve slowly and are difficult to degrade in the formation, potentially causing reservoir damage

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

[0054] The above-mentioned allyl halide may be allyl bromide or allyl chloride.

[0059] In order to make the above-mentioned quaternization reaction fully and thoroughly carried out, it can be carried out under nitrogen protection.

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

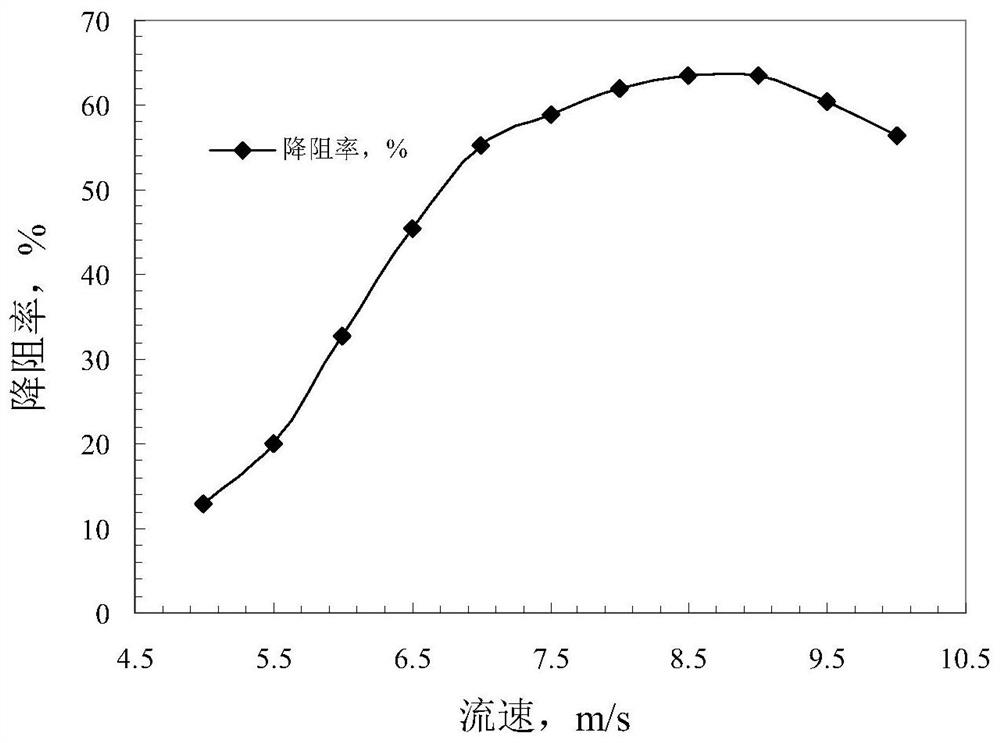

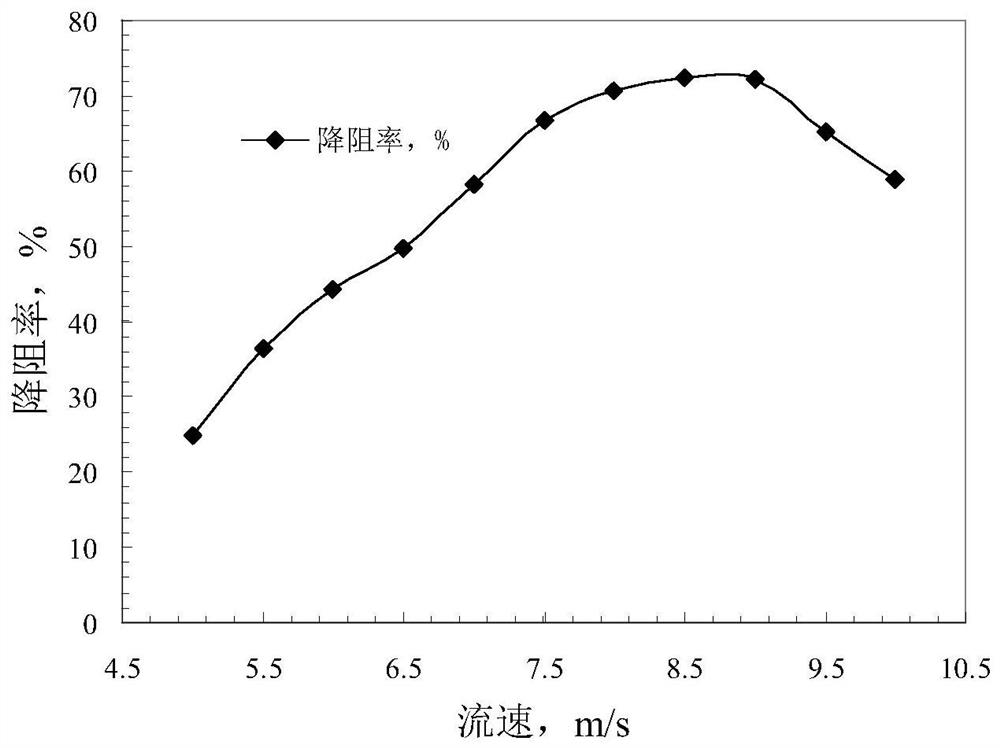

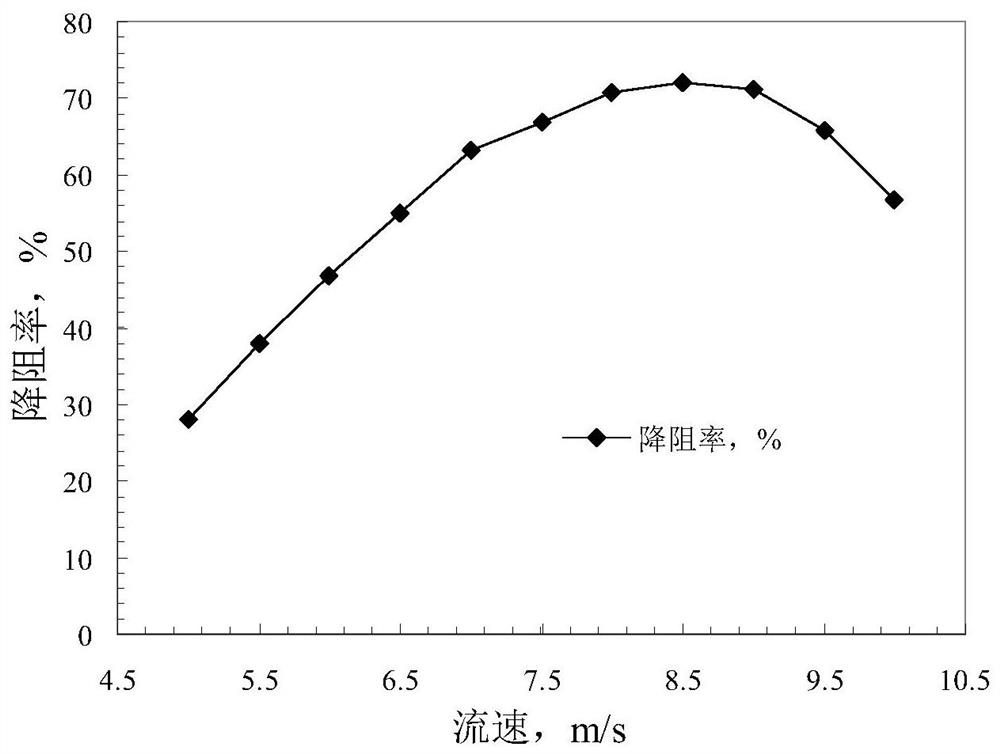

| Property | Measurement | Unit |

|---|---|---|

| resistance reduction rate | aaaaa | aaaaa |

| resistance reduction rate | aaaaa | aaaaa |

| resistance reduction rate | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a fracturing fluid and a preparation method thereof, belonging to the technical field of fracturing. The fracturing fluid includes the following components in mass percentage: 0.5%-4% of surfactant, 0.15%-2.5% of counter ion salt, 0.01%-2% of clay stabilizer, and the balance is water; the surfactant is composed of allyl Prepared by the quaternization reaction of alkyl halides and alkyldimethyl tertiary amines; the counter ion salt is phenylsulfonate. The surfactant used in the fracturing fluid is prepared by quaternization reaction of allyl halide and alkyl dimethyl tertiary amine, the reaction raw materials are cheap and easy to obtain, the reaction conditions are mild, and the reaction process is simple and easy to operate. The formed surfactant is simply compounded with the counter ion salt, which can form a viscoelastic fluid with high resistance reduction rate, and its synergistic effect with clay stabilizer and water, the formed fracturing fluid system can be used to treat Oil and gas wells are fractured to achieve excellent stimulation effects.

Description

A kind of fracturing fluid and preparation method thereof technical field [0001] The present invention relates to the technical field of fracturing, in particular to a fracturing fluid and a preparation method thereof. Background technique Hydraulic fracturing is an important measure for oil and gas well stimulation, and it utilizes high-pressure equipment to carry fracturing agents such as ceramsite. The fracturing fluid is injected into the formation to communicate the oil and gas layers and expand the drainage area, so as to achieve the purpose of increasing the production of oil and gas wells and improving the recovery factor. flow The high-speed flow of the body in the pipeline enters a turbulent state, which will generate a large frictional resistance, and part of the energy loss provided by the ground high-pressure equipment It is consumed in the pipeline, wastes the power of the pump, and shows high friction in the macroscopic view. In order to transfer the e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09K8/68C07C209/12C07C211/63

CPCC09K8/68C09K8/602C07C209/12C07C211/63

Inventor 敬显武刘友权许园李伟张亚东熊颖蒋泽银

Owner PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com