Low-pressure superheated steam integrated tower type drying device and method

A technology of superheated steam and tower drying, which is applied in the direction of drying gas arrangement, progressive dryer, and drying of solid materials without heating, etc. It can solve the problems of waste heat recovery in the device, pump damage, equipment dispersion, etc., to ensure drying Product quality, ensuring work stability, and avoiding the effect of oxidation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

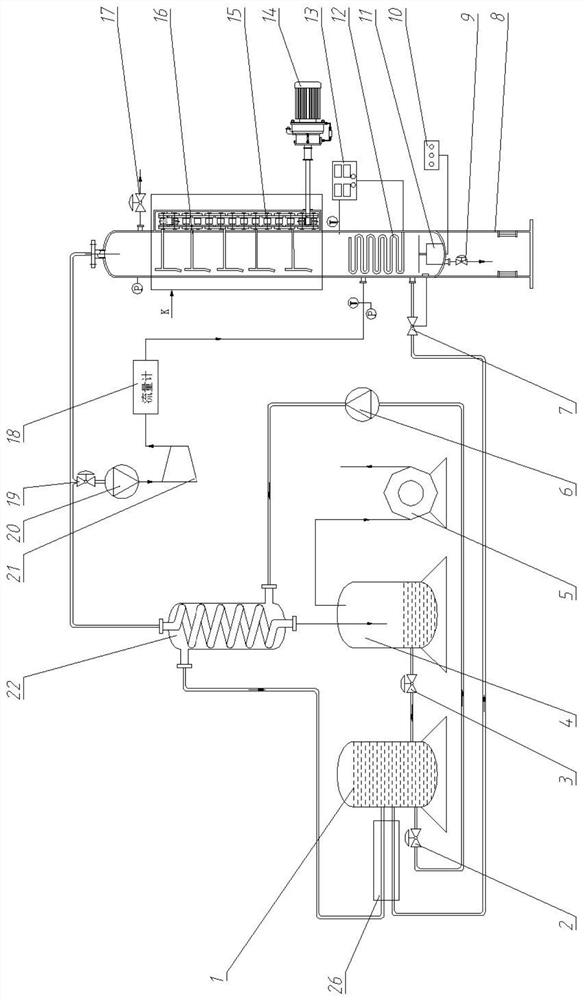

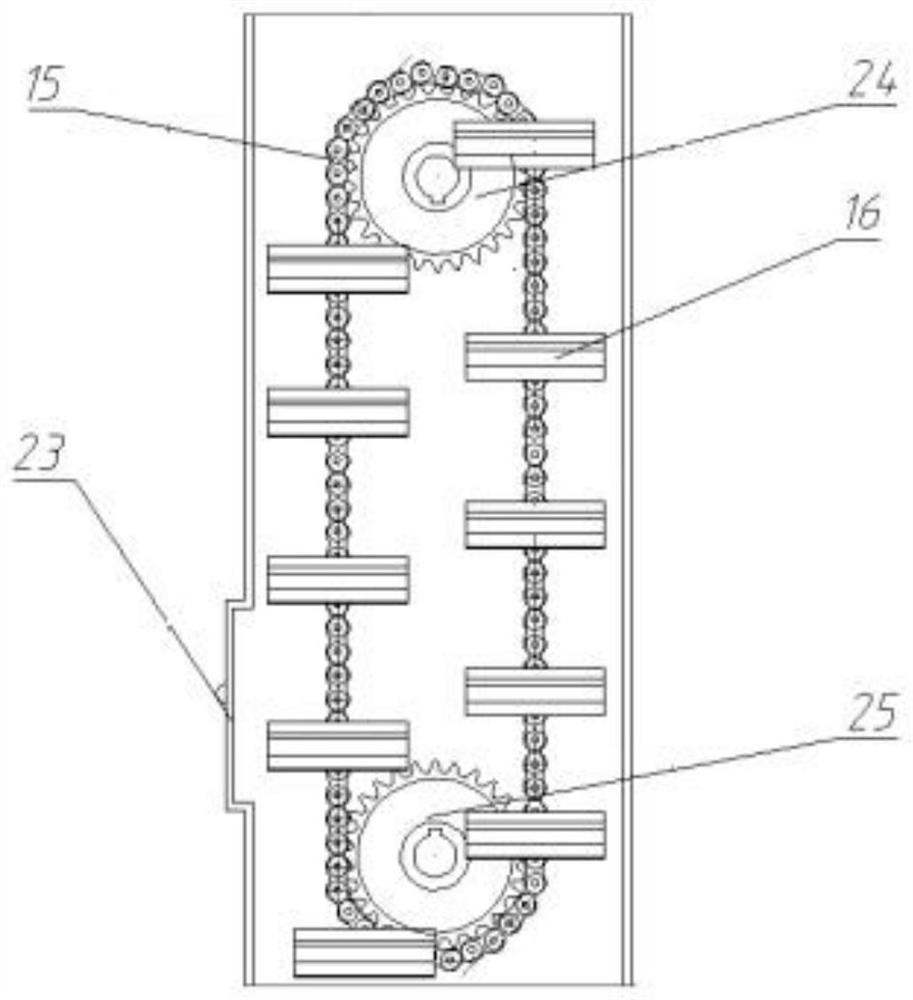

[0038] A low-pressure superheated steam integrated tower drying device, the innovation of which is that it includes a water tank 1, a limit switch solenoid valve, a liquid ring vacuum pump 5 and a drying tower 8, and one end of the water tank is connected to the In the drying tower, the other end of the water tank is connected with a liquid ring vacuum pump. The drying tower is provided with an exhaust valve 17, a tray transmission unit, a superheated steam generating unit and a drain valve 9 from top to bottom. The unit includes a motor 14, a driving sprocket 58, a driven sprocket 24, a transmission chain 15 and a tray 16, the end of the motor is connected to the driving sprocket, and the driving sprocket and the driven sprocket pass through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com