Rapid detection method for permethrin in anti-mosquito fabric

A detection method and permethrin technology are applied in the directions of measurement device, material separation, and material analysis, etc., which can solve the problems of long pretreatment time and complicated process, and achieve the effects of high sensitivity, simple detection, and shortened detection period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Detection of permethrin in textile samples with textile fiber composition of 100% lyocell:

[0040] (1) Take a textile sample with blue and white stripes and 100% lyocell, cut it into fragments or powder with a particle size of 0.5mm or less with scissors and mix evenly, weigh 0.50mg of the mixed sample, place it in a hot Crack the bottom of the sample cup; and take an appropriate amount of silanized glass wool and put it into the thermal cracking sample cup to cover the sample to prevent it from floating out;

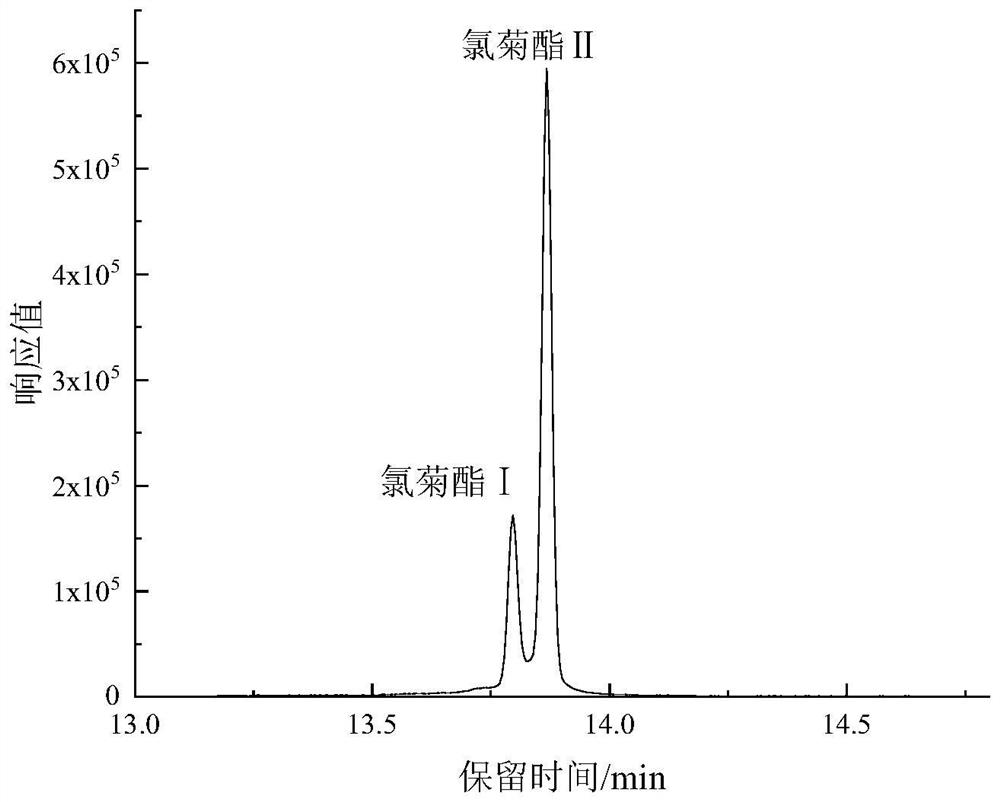

[0041] (2) Use n-hexane as a solvent, weigh the standard substance of permethrin, prepare a standard stock solution with a concentration of 1000±50 μg / mL, and then dilute it step by step to a concentration of 100 μg / mL, 10 μg / mL, and 1 μg / mL Pipette 5 μL of 1 μg / mL standard working solution, and 1 μL, 2 μL, 4 μL, 8 μL, 10 μL of 10 μg / mL standard working solution and 10 μL of 100 μg / mL standard working solution into the pyrolysis sample cup After evaporating the...

Embodiment 2

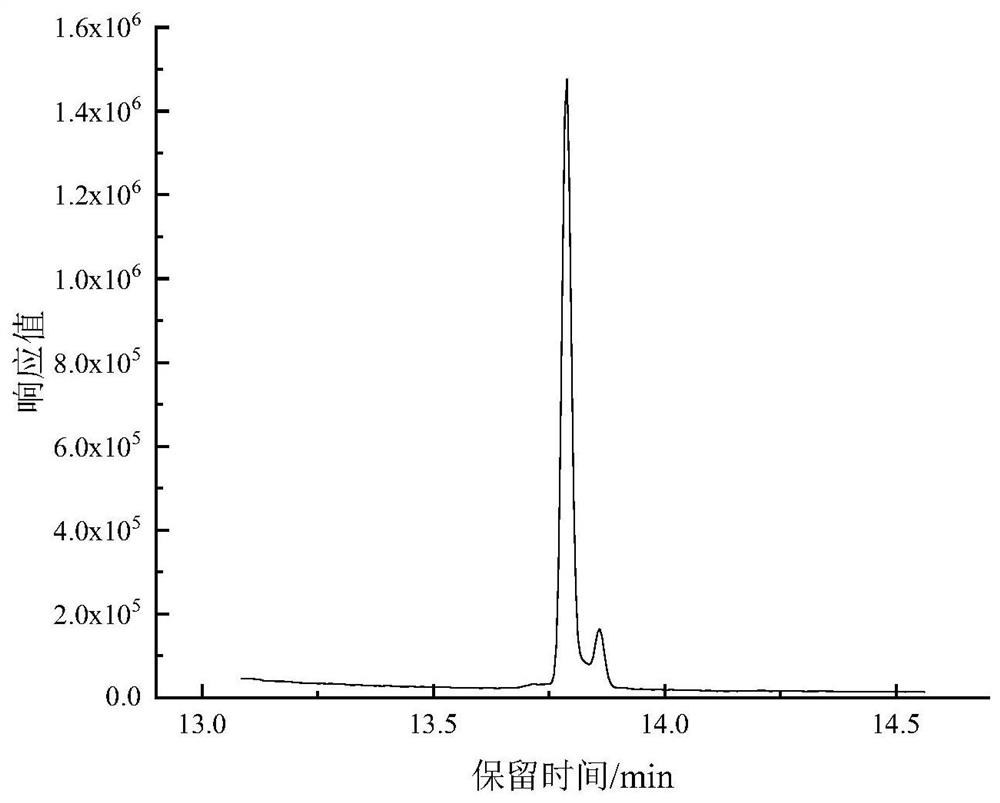

[0050] Detection of permethrin in textile samples with textile fiber composition of 9.98% spandex and 90.02% nylon:

[0051] (1) Take a red textile sample with a white background and a composition of 9.98% spandex and 90.02% nylon, cut it into fragments or powders with a particle size of 0.5mm or less with scissors and mix evenly, weigh 1.00mg of the mixed sample, Place it at the bottom of the pyrolysis sample cup; and put an appropriate amount of silanized glass wool into the pyrolysis sample cup to cover the sample to prevent it from floating out;

[0052] (2) prepare the standard item of permethrin, same as step (2) in embodiment 1;

[0053] (3) The thermal cracking sample cup described in step (1), (2) is placed in the thermal cracking equipment of thermal cracking-gas chromatography-tandem mass spectrometry, and thermal cracking-gas chromatography-tandem mass spectrometry is carried out, wherein:

[0054] The thermal cracking adopts micro-furnace heating, the thermal cra...

Embodiment 3

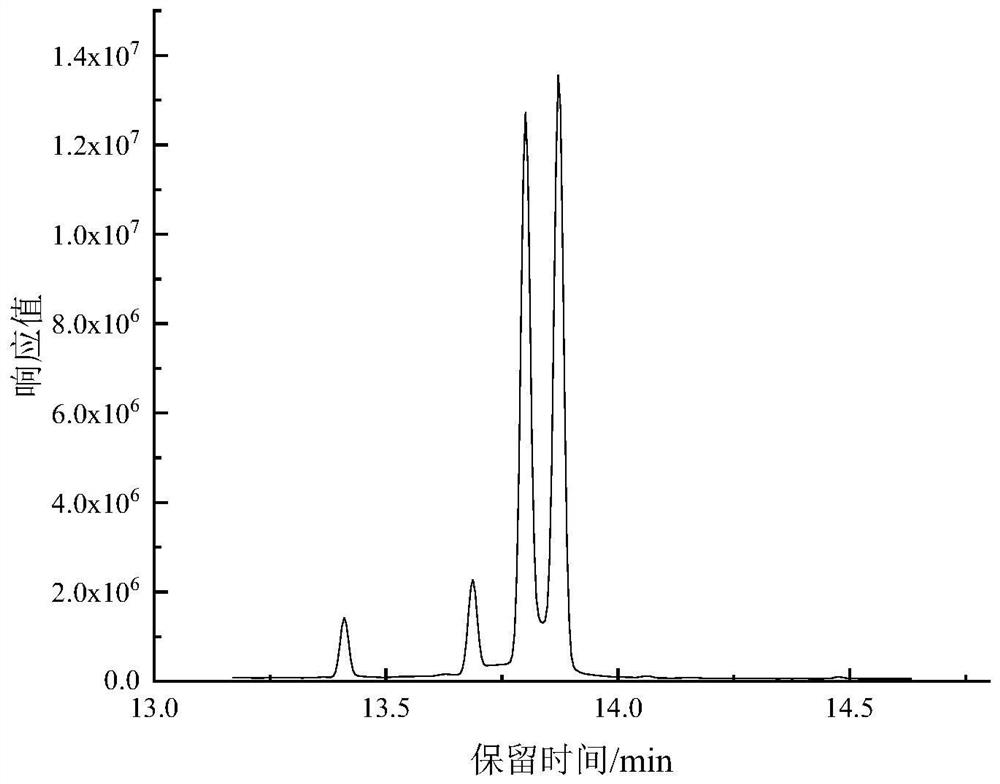

[0060] Detection of permethrin in textile samples whose textile fiber composition is 100% nylon:

[0061] (1) Select a blue textile sample with a composition of 100% nylon, cut it into fragments or powder with a particle size of 0.5 mm or less with scissors and mix evenly, weigh 1.50 mg of the mixed sample, and place it in the pyrolysis sample and put an appropriate amount of silanized glass wool into the thermal cracking sample cup to cover the sample to prevent it from floating out;

[0062] (2) prepare the standard item of permethrin, same as step (2) in embodiment 1;

[0063] (3) The thermal cracking sample cup described in step (1), (2) is placed in the thermal cracking equipment of thermal cracking-gas chromatography-tandem mass spectrometry, and thermal cracking-gas chromatography-tandem mass spectrometry is carried out, wherein:

[0064] The pyrolysis adopts micro-furnace heating, the pyrolysis temperature is 500°C, and the pyrolysis time is 40s;

[0065] The chromat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com