A kind of low-temperature silver paste for hit solar cell and preparation method thereof

A solar cell and low-temperature technology, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problems of high cost and high silver content in low-temperature silver paste of solar cells, and achieve improved conductivity Sex, increase the overlap point and overlap area, increase the effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

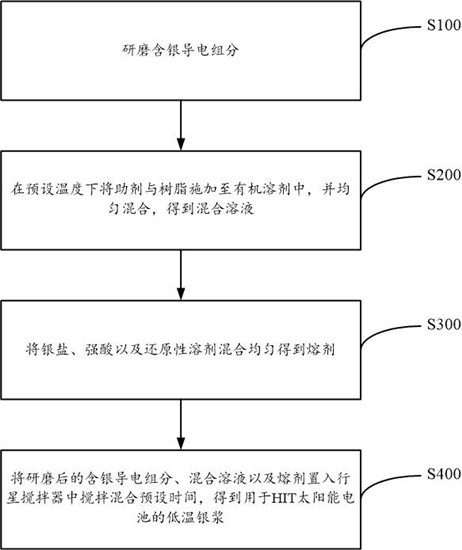

[0063] In the second aspect, the embodiment of the present disclosure provides a method for preparing a low-temperature silver paste for HIT solar cells as described above, such as figure 2 shown, including:

[0064] Step S100, grinding silver-containing conductive components;

[0065] Step S200, applying the additive and the resin to the organic solvent at a preset temperature, and uniformly mixing to obtain a mixed solution;

[0066] Step S300, uniformly mixing silver salt, strong acid and reducing solvent to obtain flux;

[0067] In step S400, the ground silver-containing conductive component, mixed solution and flux are placed in a planetary mixer and stirred for a preset time to obtain a low-temperature silver paste for HIT solar cells.

[0068] The preparation method provided by the embodiments of the present disclosure has simple process, mild conditions, and low environmental requirements, so it is suitable for large-scale production.

[0069] According to a specif...

Embodiment 1

[0077] The embodiment of the present disclosure provides a low-temperature silver paste for HIT solar cells, including the following mass percentages of raw materials: 51.5% silver-containing conductive components, 26% organic solvents, 15% resins, 0.5% surfactants, 0.8% dispersant, 0.7% coupling agent, 0.5% other additives and 5% flux. The flux is composed of 1.1% silver nitrate, 9% nitric acid and 89.9% ethanol in mass percent. The silver-containing conductive component is composed of the following components: spherical silver with a mass ratio of 65%, flake silver with a mass ratio of 30%, silver nanoparticles with a mass ratio of 3.5% and silver citrate with a mass ratio of 1.5% . The organic solvent is terpineol. The resin is a thermosetting resin. The dispersant is ethyl cellulose. The surfactant is sodium laurylate. The coupling agent is vinyltrimethoxysilane. The other additives are leveling agents.

[0078] The preparation method of this low-temperature silver ...

Embodiment 2

[0085] The difference between Embodiment 2 of the present disclosure and Embodiment 1 is that the flux is composed of 2% silver nitrate, 10% nitric acid and 88% ethanol in mass percentages. Moreover, the mass percentage of silver-containing conductive components in the low-temperature silver paste is 53.1%, and other components in the low-temperature silver paste are reduced in the same proportion. Correspondingly, in the preparation method of this low-temperature silver paste, in step 3, be respectively the silver nitrate of 2%, 10% nitric acid and 88% ethanol under the situation of stirring (rotating speed is 500r / min) Silver nitrate and nitric acid are added to ethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com