Rotor punching sheet structure

A rotor punching and punching technology, applied in the field of new energy vehicle motors, can solve the problems of high risk, weak strength, inability to take into account high efficiency, low noise, high speed and cost reduction, and achieves low cost, reduced stress, and improved The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

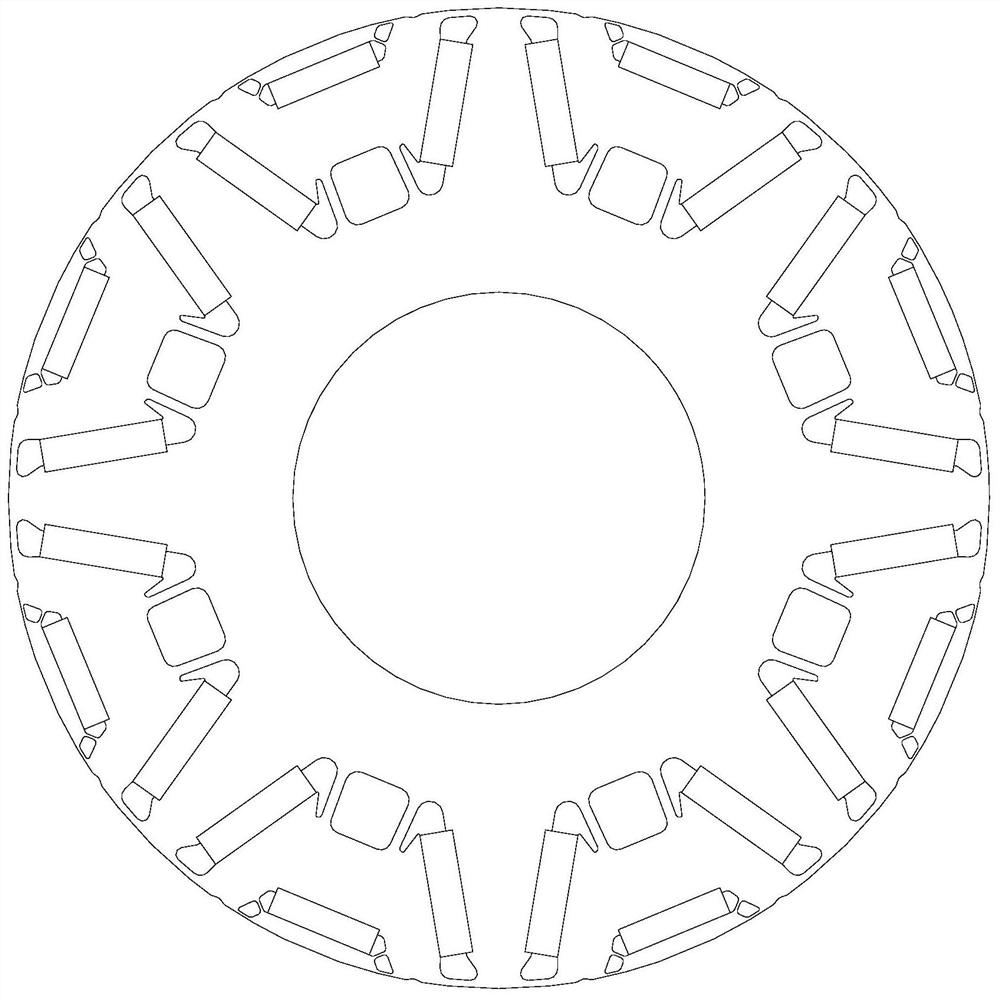

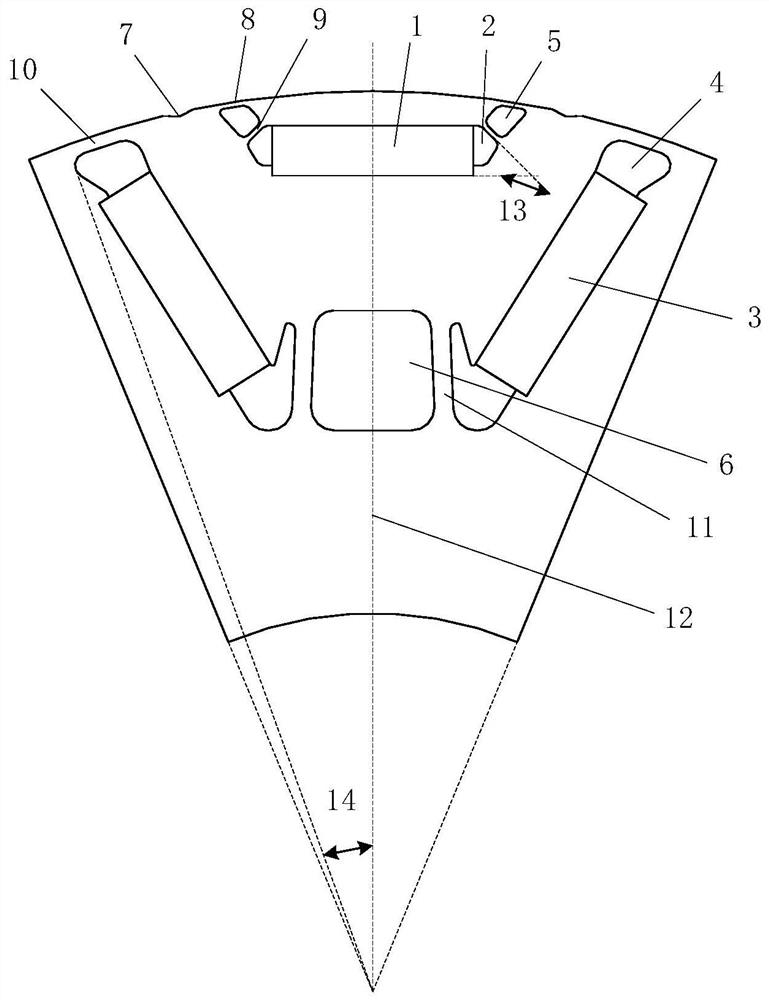

[0043] Such as figure 1 and figure 2 As shown, the present invention provides a rotor punching structure, including a punching body, on which a plurality of magnetic poles distributed symmetrically along the circumferential direction are arranged, and each magnetic pole includes a first magnetic steel groove 2, two The second magnetic steel slot 4 , two first air slots 5 and one second air slot 6 .

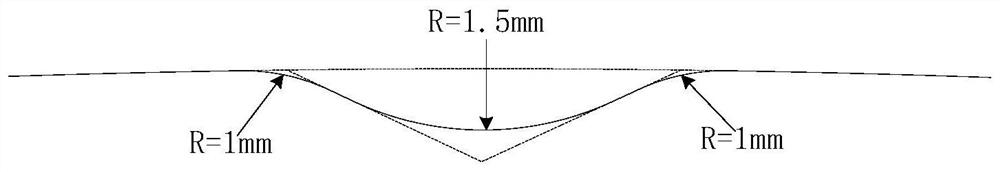

[0044] The first magnetic steel groove 2 is symmetrical about the D-axis center line 12, and the first magnetic steel groove 2 is installed with the first magnetic steel 1; two first air grooves 5 are symmetrically distributed on the outer sides of the two ends of the first magnetic steel groove 2 ; The first air groove 5 and the outer circle of the stamping body fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com