Automatic piercing hole fertilization mechanism

An automatic, fertilizing technology, applied in fertilizing devices, fertilizer distributors, excavation/covering trenches, etc., can solve the problems of high growth distance requirements, increased soil moisture loss, insufficient fertilizer utilization, etc., to achieve fertilization. High efficiency, improved utilization, simple and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

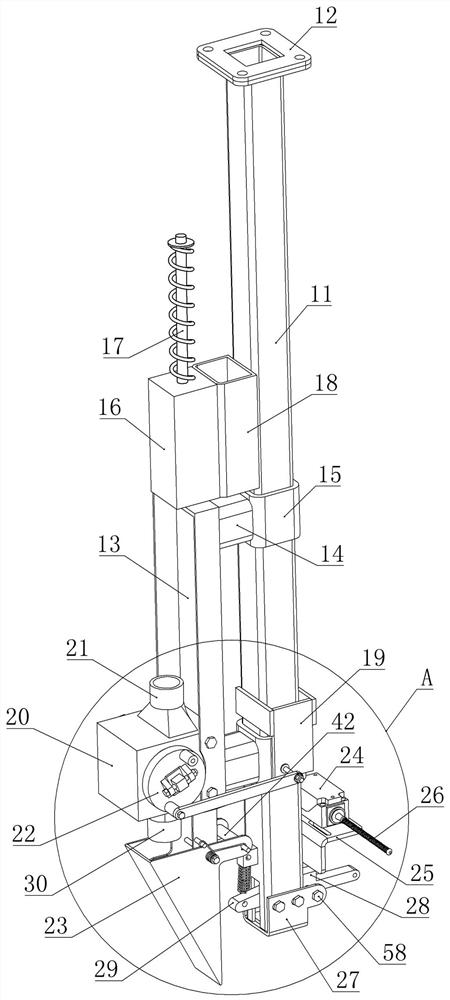

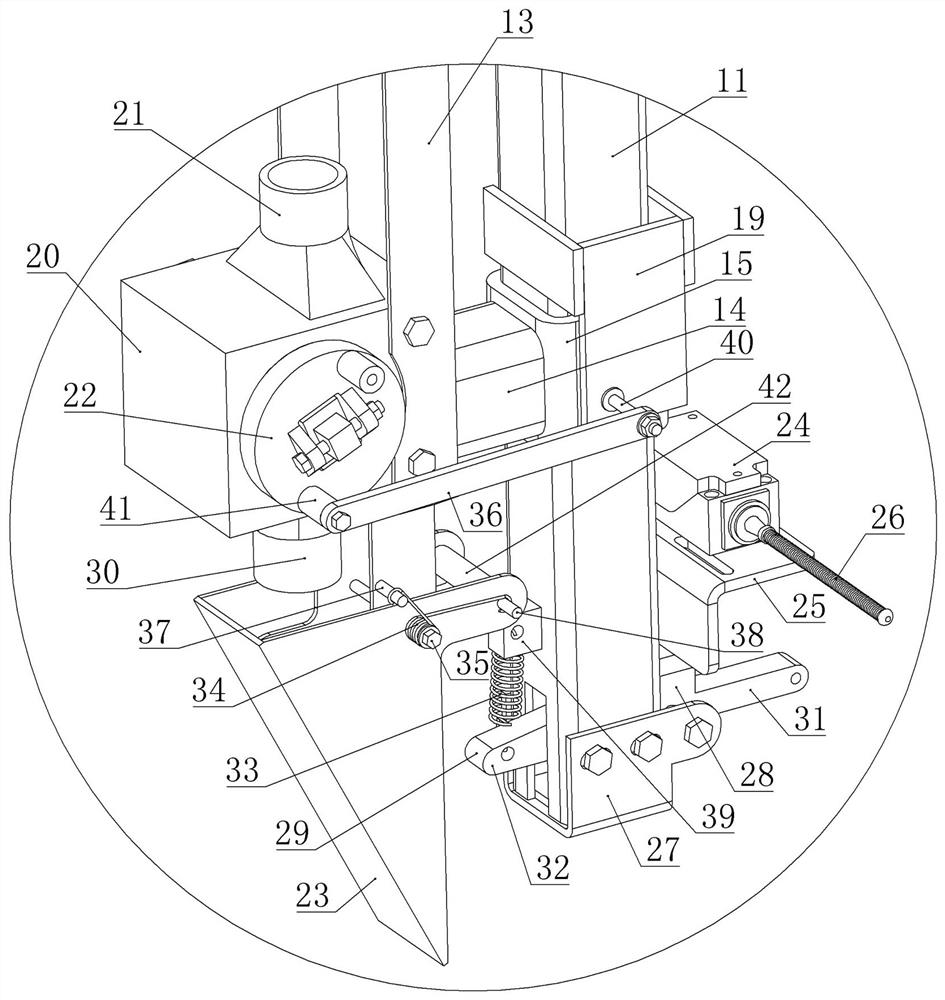

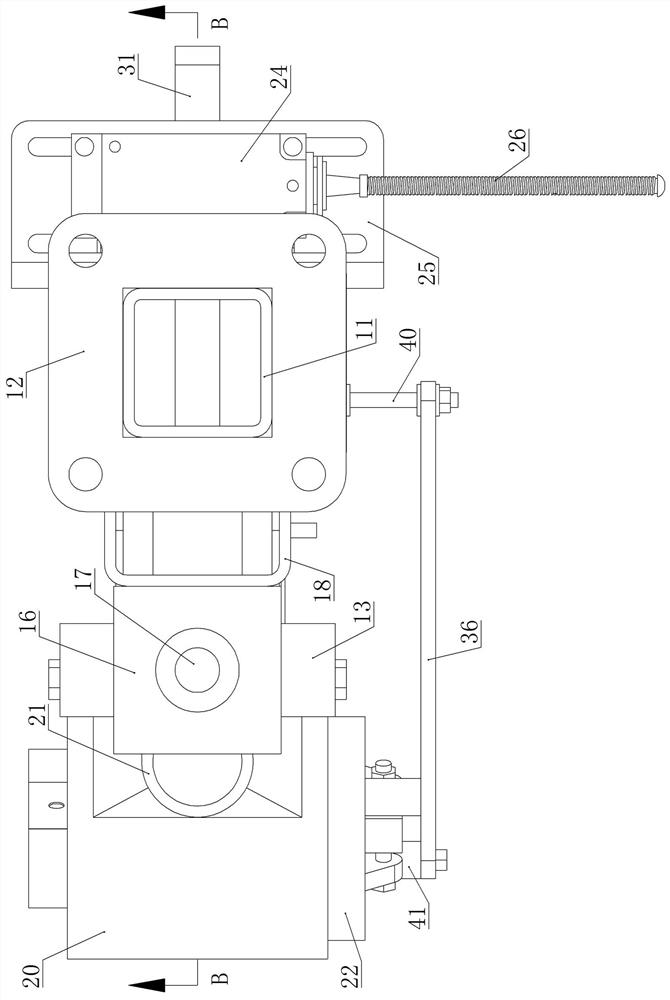

[0031] Embodiment one, see Figure 1-14 , the automatic hole-piercing fertilization mechanism, including the main rod body, the movable plate installed on the main rod body in parallel sliding, the fertilizer discharge device installed on the movable plate and the hole-piercing duckbill;

[0032]The main rod body is vertically arranged, and the movable plate is vertically arranged on the side of the main rod body, and a guide sliding sleeve matching and sleeved on the main rod body is fixed on the side of the movable plate through a connecting block, and the guide sliding sleeve is formed along the length direction of the main rod body. The sliding pair that moves vertically is provided with an electromagnet located directly above the movable plate on the side of the main rod body. The base of the electromagnet is fixed on the side of the main rod body through a pad. The telescopic rod of the electromagnet is vertically arranged and its lower end is vertical. It is fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com