Double-inlet single-outlet suction motor system and scrubber

A washing machine and motor technology, which is applied to manual floor scrubbing machinery, carpet cleaning, floor cleaning, etc., can solve the problems of reduced motor life, temperature rise of peripheral components, and slow evaporation of water vapor, so as to prevent overheating and The effect of overheating of internal parts, reducing noise, and accelerating evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

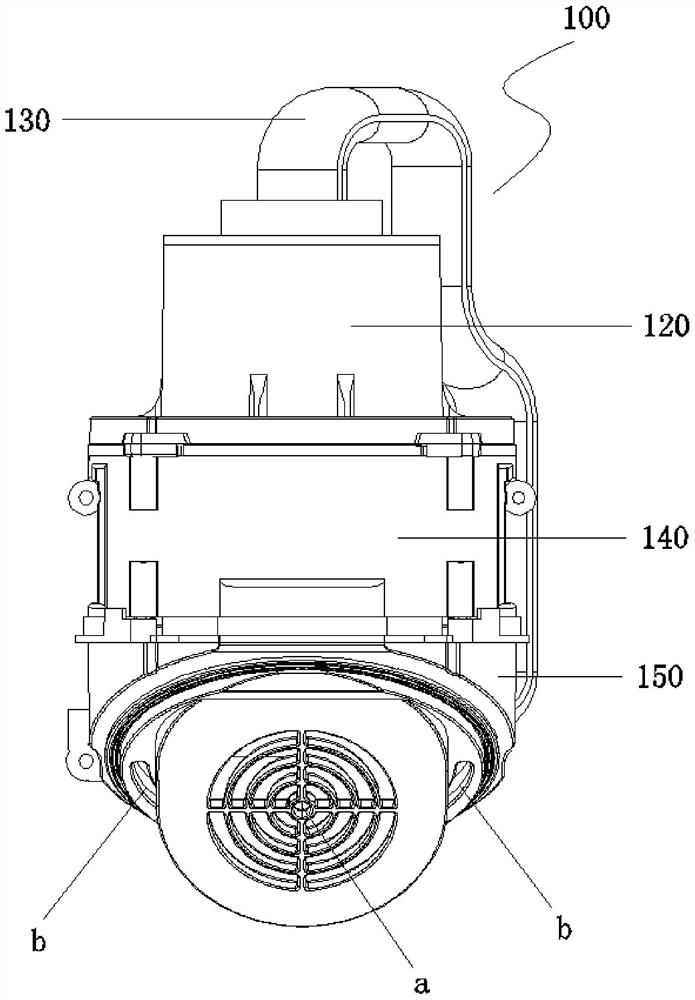

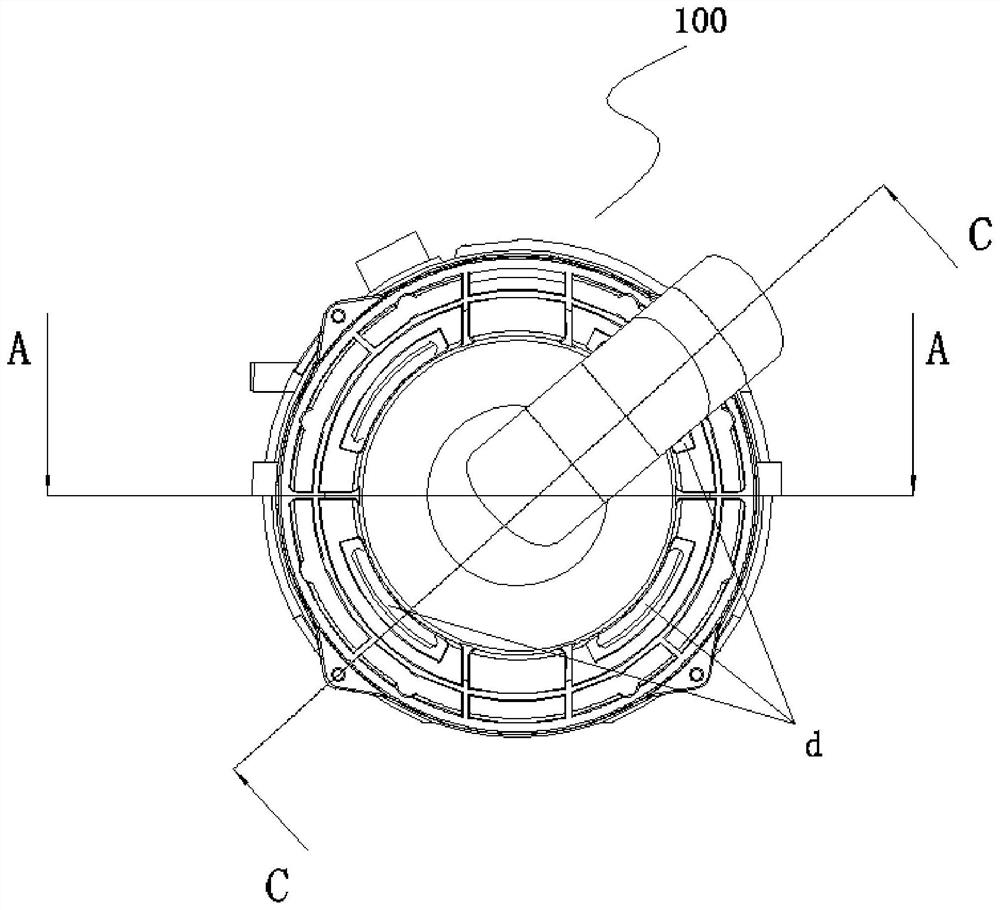

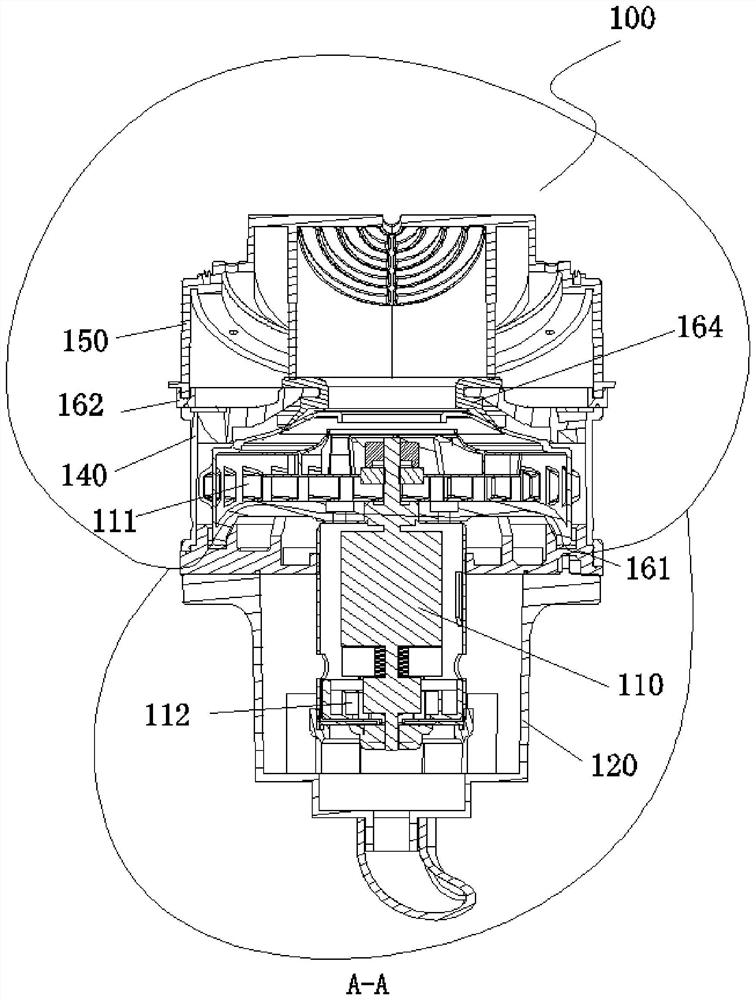

[0024] Embodiment 1: This embodiment relates to a double-inlet and single-outlet suction motor system 100, such as Figure 1-5 As shown, it includes: a vacuum cleaner motor 110 with a high-speed rotating fan blade 111 at the front end and a cooling fan blade 112 at the rear end; The assembled motor cover 120 , and the motor support sealing device arranged between the motor support and the motor cover 120 for isolating the front and rear ends of the vacuum cleaner motor 110 . The front end of the motor bracket is provided with a front central air passage a and an outer air outlet cavity b. The motor bracket is provided with a front exhaust port c. The rear end of the motor cover 120 is provided with a rear air inlet d and a rear air outlet e. A front-end air channel f is provided between the front-end central air channel a and the outer air outlet chamber b; a rear-end air channel g is provided between the rear-end air inlet d and the rear-end exhaust port e. The front exhau...

Embodiment 2

[0033] Embodiment 2: This embodiment relates to a washing machine, such as Figure 6 As shown, it includes a washing machine main body 200 and a double-inlet and single-outlet suction motor system 100 disposed in the washing machine main body 200 . The double-inlet and single-outlet suction motor system 100 is the double-inlet and single-outlet suction motor system 100 described in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com