System and method for treating waste water containing volatile substances

A technology for volatile substances and treatment systems, applied in the field of treatment systems for wastewater containing volatile substances, can solve problems such as difficult operation, excessive expansion of wastewater water volume, and large consumption of circulating water, so as to save steam consumption and energy consumption , the effect of saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

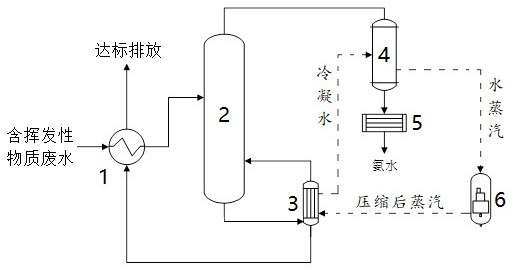

[0042] Ammonia nitrogen wastewater treatment system, such as figure 1 As shown, it includes: preheater 1, stripping rectification tower 2, reboiler 3, primary condenser 4, secondary condenser 5 and compressor 6, preheater 1 is provided with untreated waste water inlet, untreated Treated waste water outlet, treated waste water inlet and treated waste water outlet, stripping rectification tower 2 is provided with waste water inlet, tower kettle waste water outlet, waste water vaporized steam inlet and tower top ammonia-containing steam outlet, reboiler 3 is provided with waste water inlet , compressed water vapor inlet, treated waste water outlet, waste water vaporization steam outlet and condensed water outlet, the primary condenser 4 is provided with ammonia-containing steam inlet, condensed water inlet, ammonia water outlet and steam outlet, and the secondary condenser 5 is provided with Ammonia water inlet and ammonia water product outlet, compressor 6 is provided with water...

Embodiment 2

[0064] The treatment system and treatment method of ammonia nitrogen wastewater are the same as in Example 1, and the operating parameters of the stripping and rectifying tower are shown in Table 2.

[0065] Table 2 Operating parameters of the stripping distillation column

[0066] Ammonia-containing wastewater inlet flow rate of deammonization tower 125m 3 / h

Ammonia-containing wastewater inlet temperature of deamination tower 90-95℃ Ammonia-containing vapor at the top of the deamination tower 11.1t / h [range 8.3~28.5t / h] Ammonia-containing vapor temperature at the top of the deamination tower 95~100℃ Composition of ammonia-containing vapor at the top of the deammonization tower Ammonia 20%, water vapor 80% The temperature of ammonia water recovered from the top of the tower after being condensed by the top condenser 35℃ Amount of steam consumed by deamination tower (direct heating) About 13t / h, subject to 0.4MPa saturated s...

Embodiment 3

[0073] Treatment systems for ethanol-containing wastewater, such as figure 1 As shown, it includes: preheater 1, stripping rectification tower 2, reboiler 3, primary condenser 4, secondary condenser 5 and compressor 6, preheater 1 is provided with untreated waste water inlet, untreated Treated waste water outlet, treated waste water inlet and treated waste water outlet, stripping rectification tower 2 is provided with waste water inlet, tower kettle waste water outlet, waste water vaporization steam inlet and tower top ethanol-containing steam outlet, reboiler 3 is provided with waste water inlet , compressed water vapor inlet, treated waste water outlet, waste water vaporization steam outlet and condensed water outlet, the primary condenser 4 is provided with ethanol-containing steam inlet, condensed water inlet, ethanol outlet and water vapor outlet, and the secondary condenser 5 is provided with Ethanol inlet and ethanol product outlet, compressor 6 is provided with water v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com