Monodisperse polymer porous microsphere and preparation method thereof

A technology of porous microspheres and polymers, which is applied in the field of monodisperse polymer porous microspheres and their preparation, can solve the problems of pore collapse, difficulty in removing templates completely, and difficulty in realizing individual regulation of polymer porous microspheres, and achieves macropore size. The effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

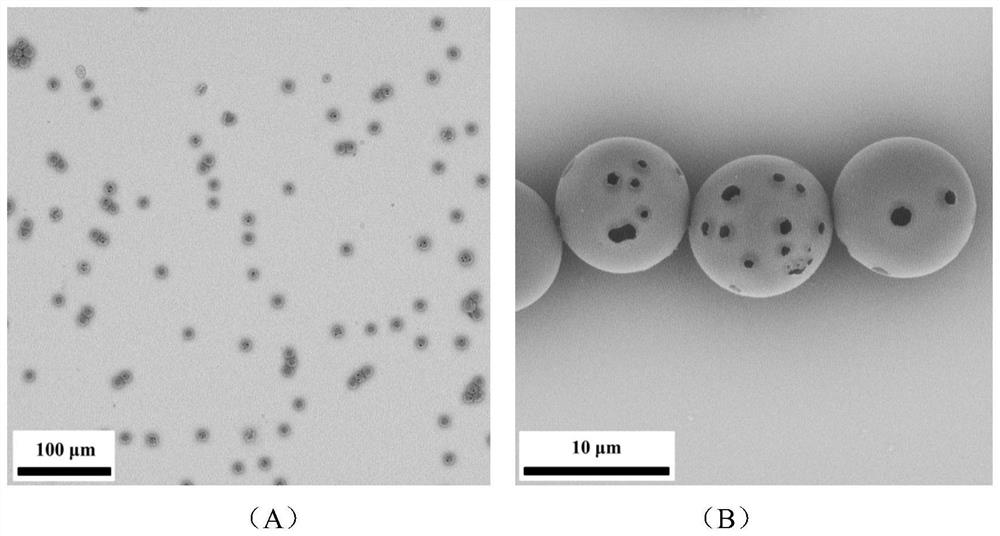

Embodiment 1

[0057] In this embodiment, monodisperse polystyrene (PS) solid microspheres are used as the particles of polymer A, and polyvinylpyrrolidone (PVP) is used as polymer B to prepare monodisperse PS porous microspheres, which specifically include the following steps :

[0058] (1) Preparation of blend

[0059] Weigh 3.0g of PVP, measure 30mL of distilled water, dissolve PVP in water to form a PVP aqueous solution; weigh 0.9g of monodisperse PS solid microspheres with a particle size of 10.0±0.2μm, and fully disperse the PS solid microspheres in the PVP aqueous solution , and then dry the water to obtain the PS solid microsphere / PVP blend.

[0060] (2) High-pressure fluid foaming

[0061] Place the PS solid microsphere / PVP blend obtained in step (1) in an autoclave, feed carbon dioxide into the autoclave as a foaming agent, control the pressure in the autoclave to 30MPa and the temperature to 60°C, and maintain the aforementioned pressure and temperature Condition 1h, the foamin...

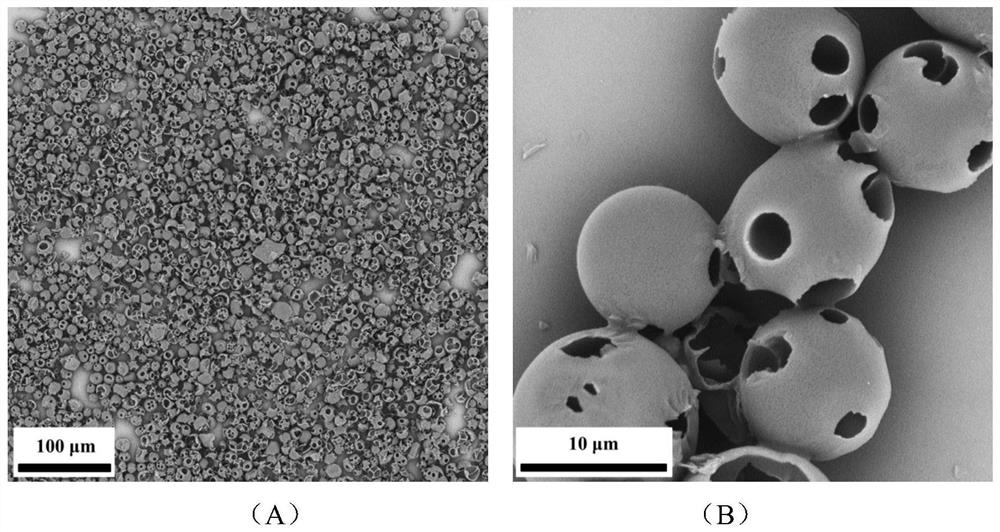

Embodiment 2

[0066] In this embodiment, monodisperse PS solid microspheres are used as the particles of polymer A, and PVP is used as polymer B to prepare monodisperse PS porous microspheres, which specifically include the following steps:

[0067] (1) Preparation of blend

[0068] Weigh 3.0g of PVP, measure 30mL of distilled water, dissolve PVP in water to form a PVP aqueous solution; weigh 0.9g of monodisperse PS solid microspheres with a particle size of 10.0±0.2μm, and fully disperse the PS solid microspheres in the PVP aqueous solution , and then dry the water to obtain the PS solid microsphere / PVP blend.

[0069] (2) High-pressure fluid foaming

[0070] Place the PS solid microsphere / PVP blend obtained in step (1) in an autoclave, feed nitrogen into the autoclave as a foaming agent, control the pressure in the autoclave to be 3MPa, and the temperature to be room temperature, and maintain the aforementioned pressure and temperature conditions After 24 hours, the foaming agent reache...

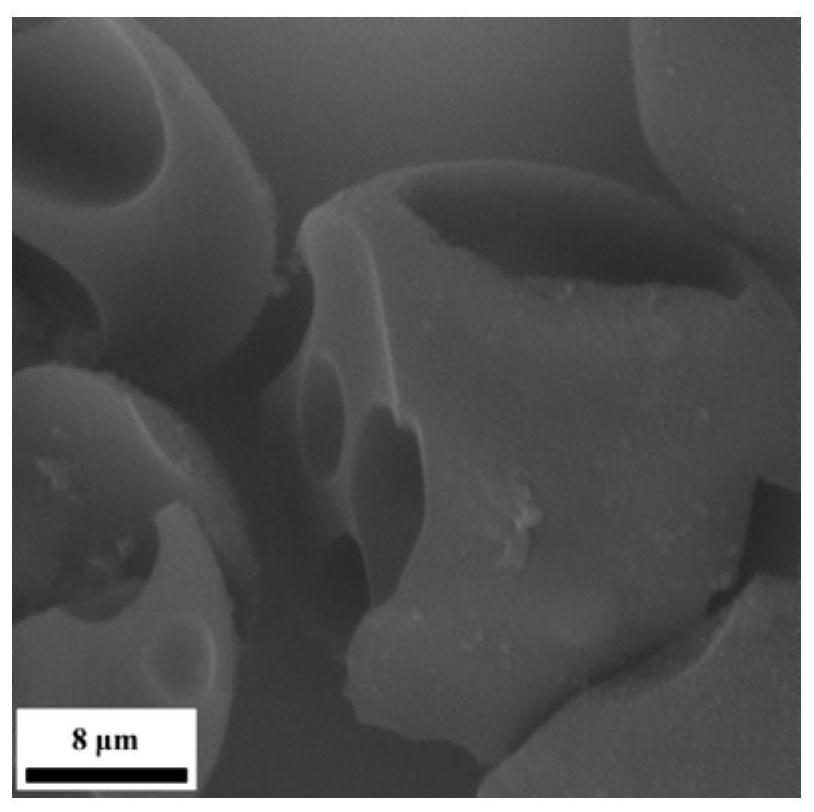

Embodiment 3

[0075] In this example, monodisperse PS solid microspheres are used as the particles of polymer A, and PVP is used as polymer B to prepare monodisperse PS porous microspheres. The PS porous microspheres have a hierarchical porous structure, specifically including the following step:

[0076] (1) Preparation of blend

[0077] Weigh 3.0g of PVP, measure 30mL of distilled water, dissolve PVP in water to form a PVP aqueous solution; weigh 0.9g of monodisperse PS solid microspheres with a particle size of 500.0±5.0μm, and fully disperse the PS solid microspheres in the PVP aqueous solution , and then dry the water to obtain the PS solid microsphere / PVP blend.

[0078] (2) High-pressure fluid foaming

[0079] Place the PS solid microsphere / PVP blend obtained in step (1) in an autoclave, feed nitrogen into the autoclave as a foaming agent, control the pressure in the autoclave to 15MPa, and the temperature to 100°C, and maintain the aforementioned pressure and temperature Conditio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com