Preparation method of high-hardness and low-warpage double-layer small-particle solid fluorescent adhesive film

A solid-state fluorescent, low-warping technology, applied in the field of fluorescent film, can solve problems such as poor operation performance of thimbles, easy scratches on the surface of the package, and influence on LED performance, so as to ensure product transparency and increase product moisture resistance. , Improve the effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

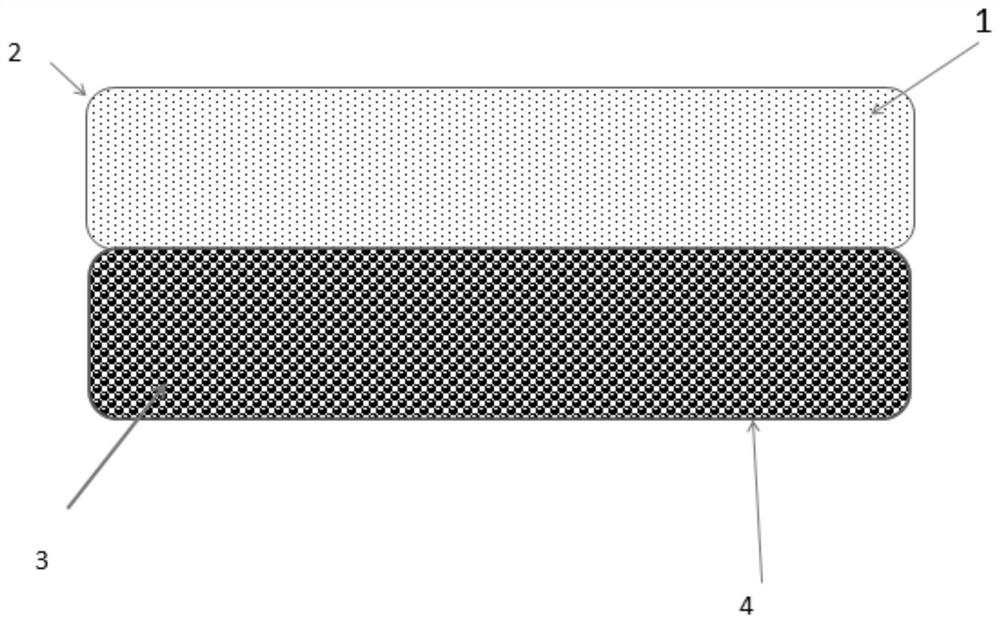

[0028] The invention provides a method for preparing a double-layer small-particle solid-state fluorescent film with high hardness and low warpage. The preparation method includes the following steps:

[0029] Step 1: Scratch the fluorescent adhesive film on the release film;

[0030] Step 2: Scrape and coat the transparent film on the release film;

[0031] Step 3: Superimpose the fluorescent film and the transparent film using a vacuum press;

[0032] Step 4: cutting the obtained material after curing at high temperature.

[0033] [Fluorescent film]

[0034] The fluorescent adhesive film prepared by the above method is a semi-cured prepolymer of silicone resin. In some embodiments, the fluorescent adhesive film has a thickness of 30-70 μm.

[0035] Preferably, the raw materials for the preparation of the fluorescent adhesive film include, in parts by weight, 20-99 parts of silicone resin and 1-80 parts of fluorescent powder.

[0036] Further, the raw materials for the...

Embodiment 1

[0089] Embodiment 1 provides a preparation method of a silicone transparent film containing micron-scale inorganic fillers according to the present invention, wherein the micron-scale inorganic fillers are 0 wt%, and the content of DM-30 is 1 wt%.

Embodiment 2

[0090] Embodiment 2 provides a method for making a silicone transparent film containing micron-scale inorganic fillers according to the present invention, wherein the micron-scale inorganic fillers are 50 wt%, and the content of DM-30 is 1 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com