Epoxy resin hot melt adhesive and preparation method thereof

A technology of epoxy resin and hot melt adhesive, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of low application value, low bonding strength, poor corrosion resistance, etc., and achieve strong interaction, The effect of improving the bonding strength and excellent bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of above-mentioned epoxy-based hot-melt adhesive, by:

[0051] Polyetheramines with one amine group:

[0052]

[0053] Polyetheramine UPy derivatives containing one amine group:

[0054]

[0055] and epoxy resins with two epoxy groups:

[0056]

[0057] Adopt melting method to carry out reaction and obtain, the molecular formula of the hot-melt adhesive based on epoxy resin obtained is as follows:

[0058]

[0059] The concrete process of above-mentioned preparation method is:

[0060] Prepare raw materials in molar portions;

[0061] Under high temperature conditions, polyetheramine, polyetheramine UPy derivatives and epoxy resin are fully stirred and mixed to obtain an epoxy resin hot melt adhesive prepolymer;

[0062] Under high temperature conditions, the epoxy resin hot melt adhesive prepolymer is cured for a period of time to obtain the epoxy resin hot melt adhesive.

[0063] In the above-mentioned preparation method, prepare ...

Embodiment 1

[0088] a is 1, b is 6.4, z is 0.18, m is 9, n is 1, and α=0.5.

[0089]

[0090] Weigh:

[0091] Epoxy resin: 3.92g

[0092] Polyetheramine: 3.01g

[0093] Polyetheramine UPy derivative: 3.01g

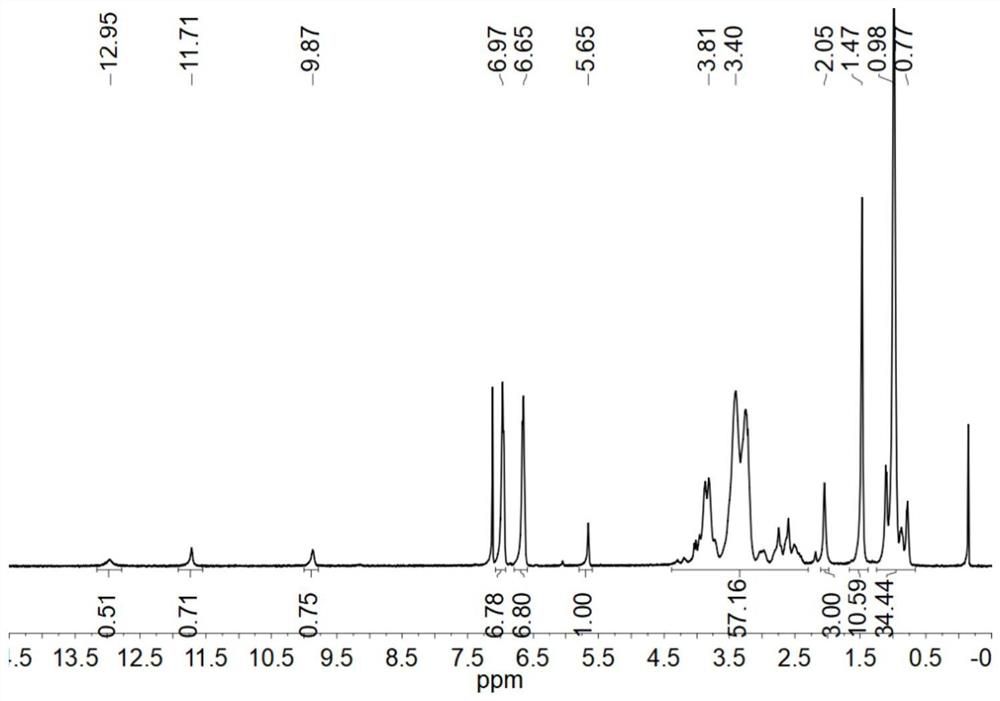

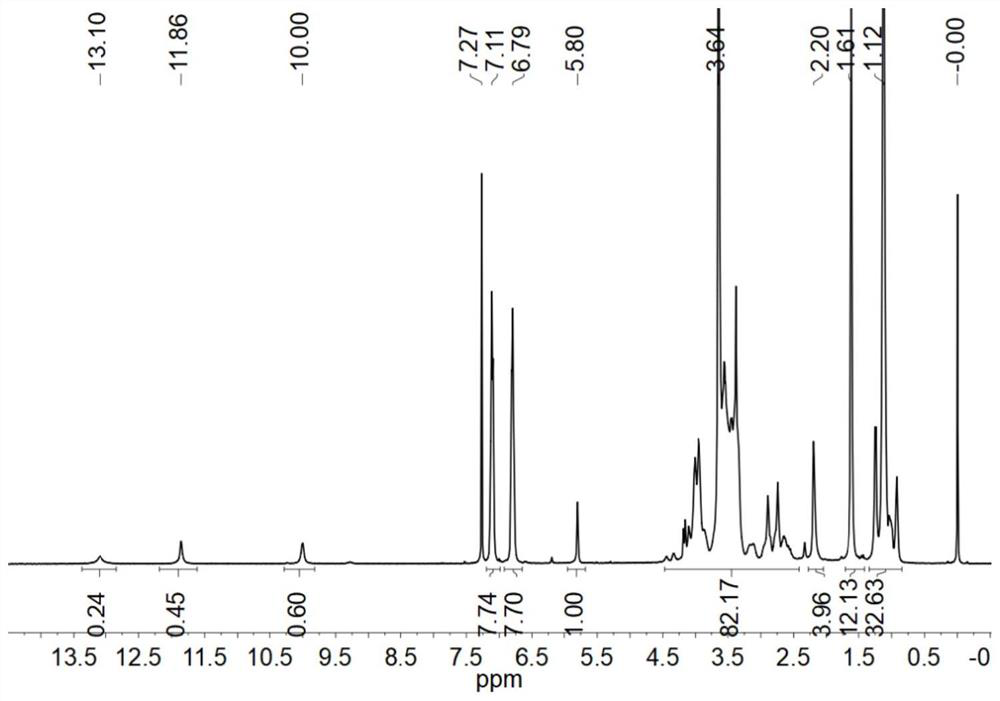

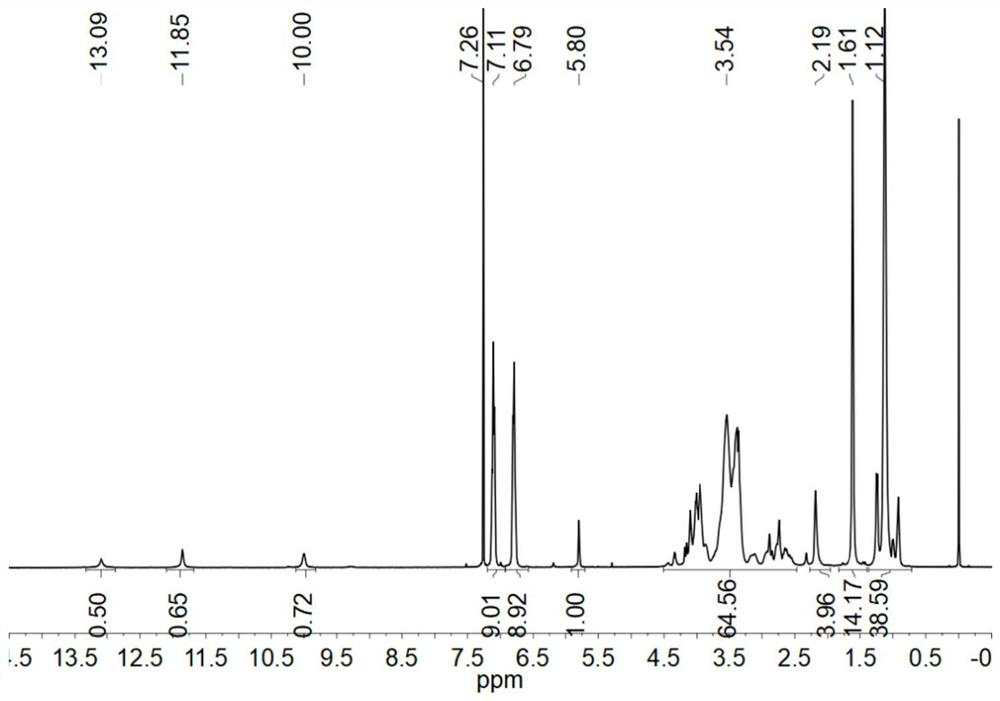

[0094] Stir and mix polyetheramine, polyetheramine UPy derivatives and epoxy resin at 50°C for 0.5 hours, pour it into a polytetrafluoroethylene watch glass after fully stirring, and cure at 50°C for 24 hours. Cool to room temperature, obtain 9.43g epoxy resin hot-melt adhesive, productive rate is 95%. The lap shear strength was measured at 2.72 MPa. 1 H-NMR (CDCl 3 ),δ(ppm):12.95(s,0.50H),11.71(s,0.71H),9.87(s,0.75H),6.97(d,10.21H),6.65(d,10.13H),5.65(s ,1H),3.40(m,89.14H),2.05(s,3.31H),1.47(s,16.1H),0.98(m,54.15H).

Embodiment 2

[0096] a is 1, b is 6.4, z is 0.18, m is 9, n is 1, and α=0.8.

[0097]

[0098] Weigh:

[0099] Epoxy resin: 3.92g

[0100] Polyetheramine: 1.20g

[0101] Polyetheramine UPy derivative: 4.80g

[0102] Stir and mix polyetheramine, polyetheramine UPy derivatives and epoxy resin at 60°C for 0.1 hour, pour it into a polytetrafluoroethylene watch glass after fully stirring, and cure at 60°C for 12 hours. Cool to room temperature, obtain 8.93g epoxy resin hot-melt adhesive, productive rate is 90%. The lap shear strength was measured to be 10.04 MPa. The nuclear magnetic pattern of the hot-melt adhesive of the preparation of present embodiment two is as figure 1 As shown, the infrared spectrum of the hot melt adhesive is shown as Figure 9 shown. 1 H-NMR (CDCl 3 ),δ(ppm):12.95(s,0.51H),11.71(s,0.71H),9.87(s,0.75H),6.97(d,6.78H),6.65(d,6.80H),5.65(s ,1H),3.40(m,57.16H),2.05(s,3H),1.47(s,10.59H),0.98(m,34.44H).

PUM

| Property | Measurement | Unit |

|---|---|---|

| lap shear strength | aaaaa | aaaaa |

| lap shear strength | aaaaa | aaaaa |

| lap shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com