A prechamber ignition internal combustion engine controlled by jet valve

A pre-combustion chamber and jet valve technology, applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of increasing jet ignition energy, throttling loss and heat loss, early combustion of internal combustion engines, etc., to reduce combustion Effects of cycle fluctuation, volume reduction, and life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0141] A pre-combustion chamber ignition internal combustion engine controlled by a jet valve has a cylinder body, a cylinder head, a cylinder, a piston, a connecting rod, a crankshaft, intake and exhaust valves, an intake system, an exhaust system and an EGR system. The piston reciprocates in the cylinder, the piston pin hole on it is connected to one end of the connecting rod, and the other end of the connecting rod is connected to the crankpin of the crankshaft. The reciprocating motion of the piston pushes the crankpin to rotate around the center of the crankshaft and output power to the outside.

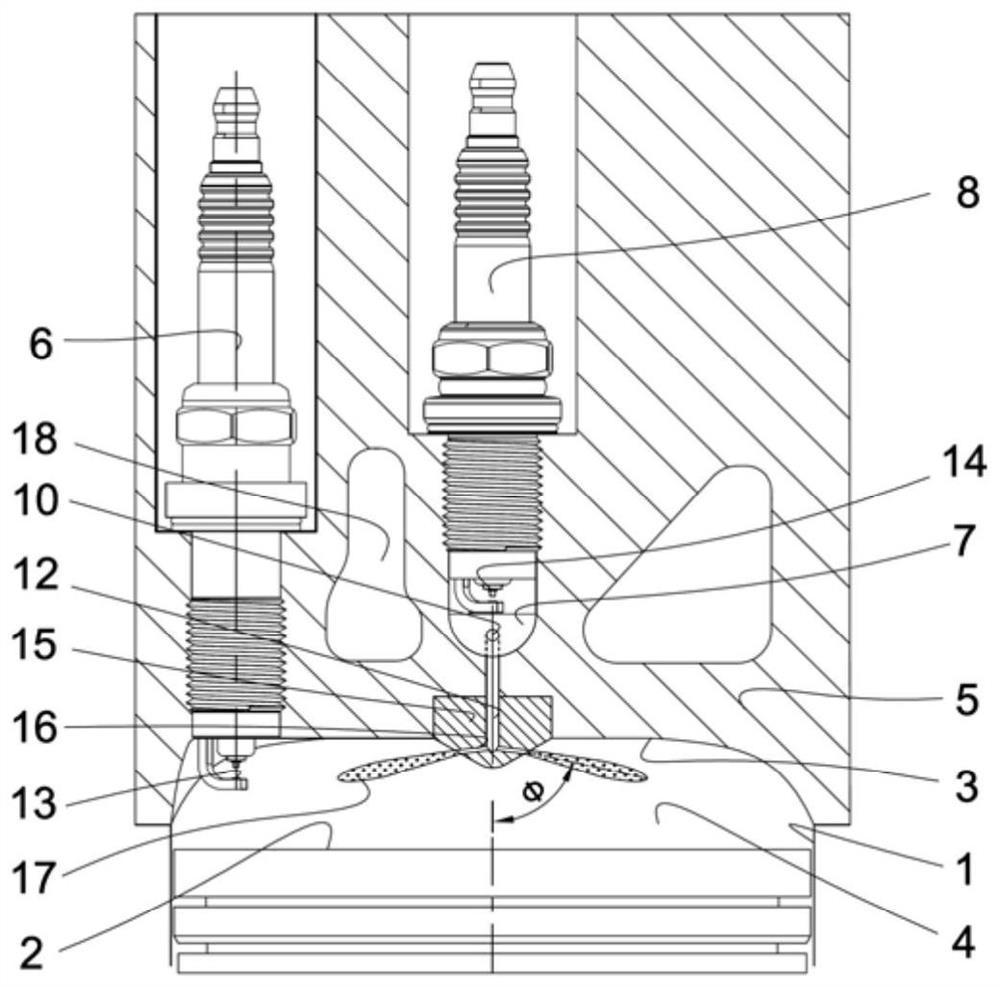

[0142] figure 1 As shown, the cavity between the inner peripheral wall of the cylinder 1, the top surface of the piston 2 and the lower end surface of the cylinder head 5 forms a main combustion chamber 4, and at least one intake valve is arranged on the top surface 3 of the main combustion chamber near the intake side, It is used for the intake air of the cylinder 1, and at lea...

Embodiment 2

[0180] Figure 5 As shown, a jet valve-controlled pre-combustion chamber ignition internal combustion engine and its operating mode, for each cylinder of the internal combustion engine, a main spark plug 6 is respectively arranged on the side of the cylinder head 5 on the top surface 3 of the main combustion chamber , a pre-chamber 7, a pre-chamber spark plug 8, a jet valve 20, a one-way intake valve 90, a jet channel 12 leading from the pre-chamber 7 to the main combustion chamber 4, a jet passage 12 from the main combustion chamber 4 A passive intake channel 91 leading to the pre-chamber 7 , a valve nozzle 25 and at least one injection hole 16 . in:

[0181] The main spark plug 6 is arranged near the center of the cylinder 1 in the cylinder head 5 or on one side of the outer circumference of the cylinder 1, preferably on the outer circumference side of the cylinder 1, and the main spark plug electrode 13 faces the main combustion chamber 4, which can be used for Ignite the...

Embodiment 3

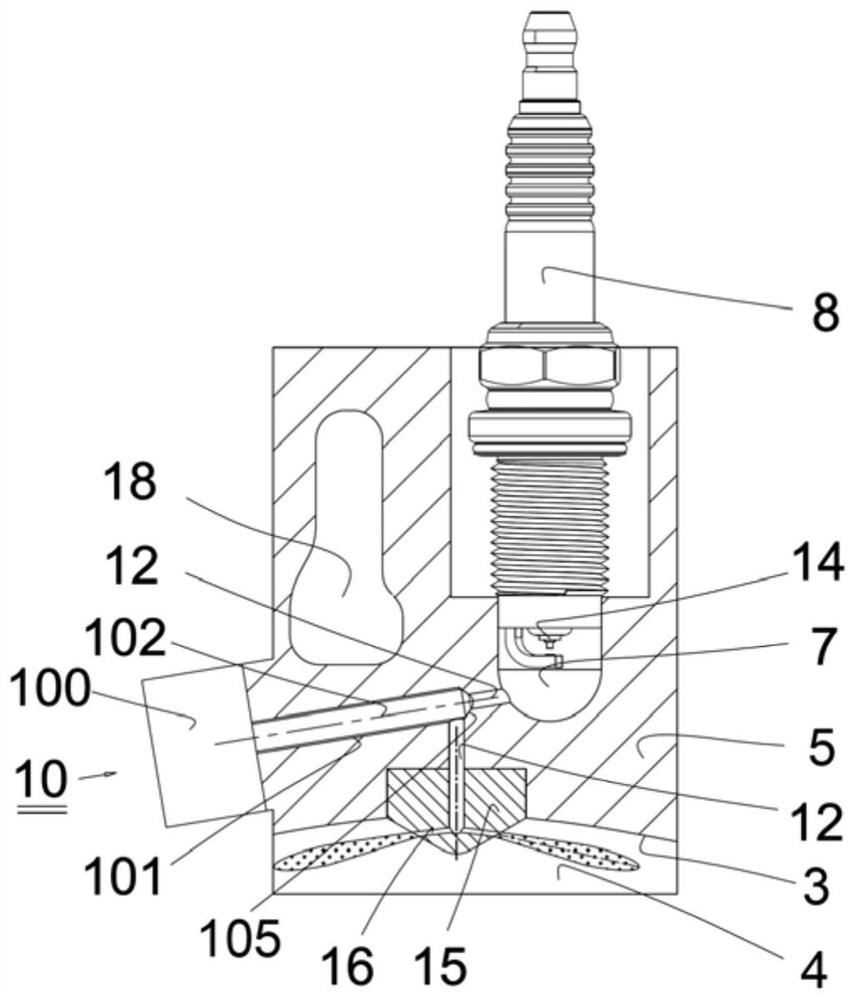

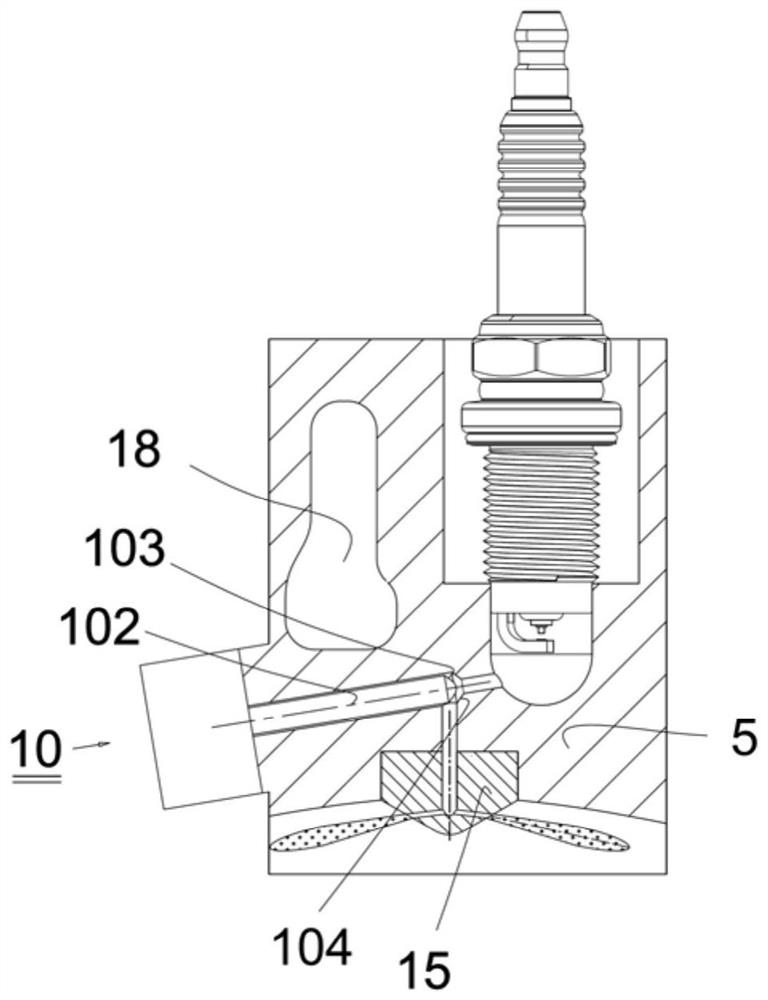

[0227] Figure 13 As shown, a jet valve-controlled pre-combustion chamber ignition internal combustion engine and its operating mode, for each cylinder of the internal combustion engine, a main spark plug 6 is respectively arranged on the side of the cylinder head 5 on the top surface 3 of the main combustion chamber , a pre-chamber 7, a pre-chamber spark plug 8, a jet valve 10, an intake valve 9, a jet channel 12 leading from the pre-chamber 7 to the main combustion chamber 4, a jet channel 12 leading from the intake valve 9 to the The active intake channel 11 of the prechamber 7 , a nozzle 15 and at least one injection hole 16 .

[0228] in:

[0229] The main spark plug 6 is arranged near the center of the cylinder 1 in the cylinder head 5 or on one side of the outer circumference of the cylinder 1, preferably on the outer circumference side of the cylinder 1, and the main spark plug electrode 13 faces the main combustion chamber 4, which can be used for Ignite the main mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com