A method for optimizing the operation of the oxidation fan in a single-tower double-circulation desulfurization device

A technology of oxidation fan and desulfurization device, which is applied in chemical instruments and methods, separation methods, design optimization/simulation, etc., can solve the problems of unfavorable slurry quality control in the desulfurization tower, affecting pH value partition control, poor energy saving effect, etc., and achieves Significant economic benefits and promotion value, saving land resources and space, and improving the effect of energy conservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solution of the present invention will be further specifically described below through examples, and these examples are done to illustrate the present invention, not to limit the present invention. Based on the embodiments in this application, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the scope of protection of this application.

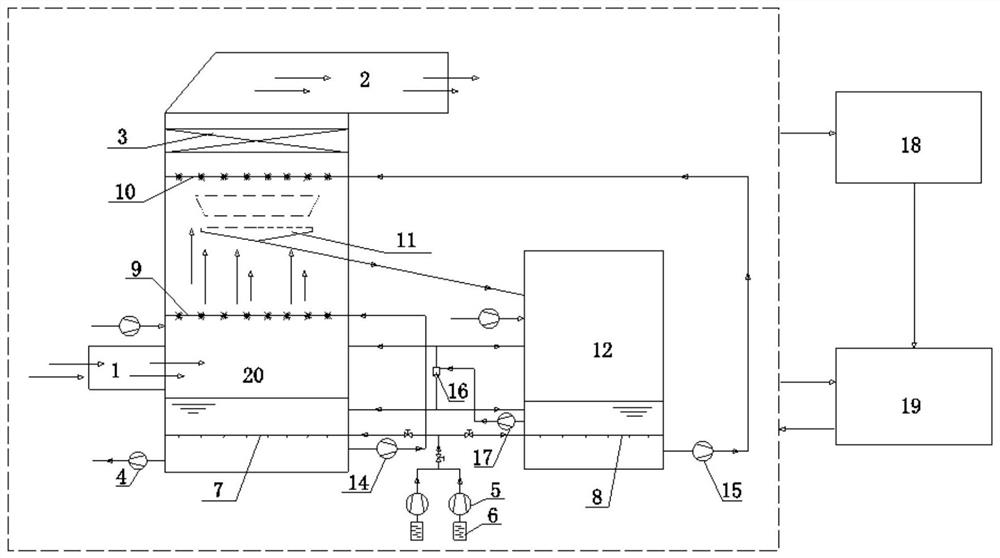

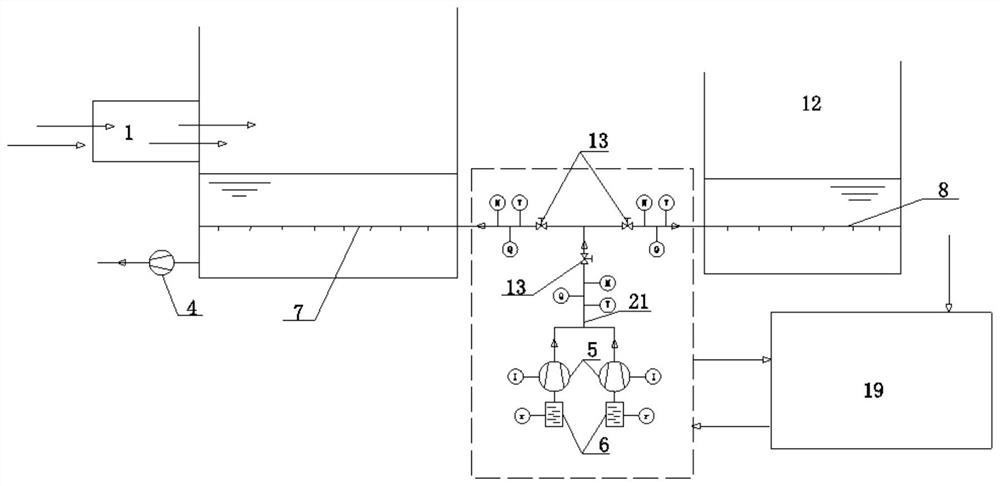

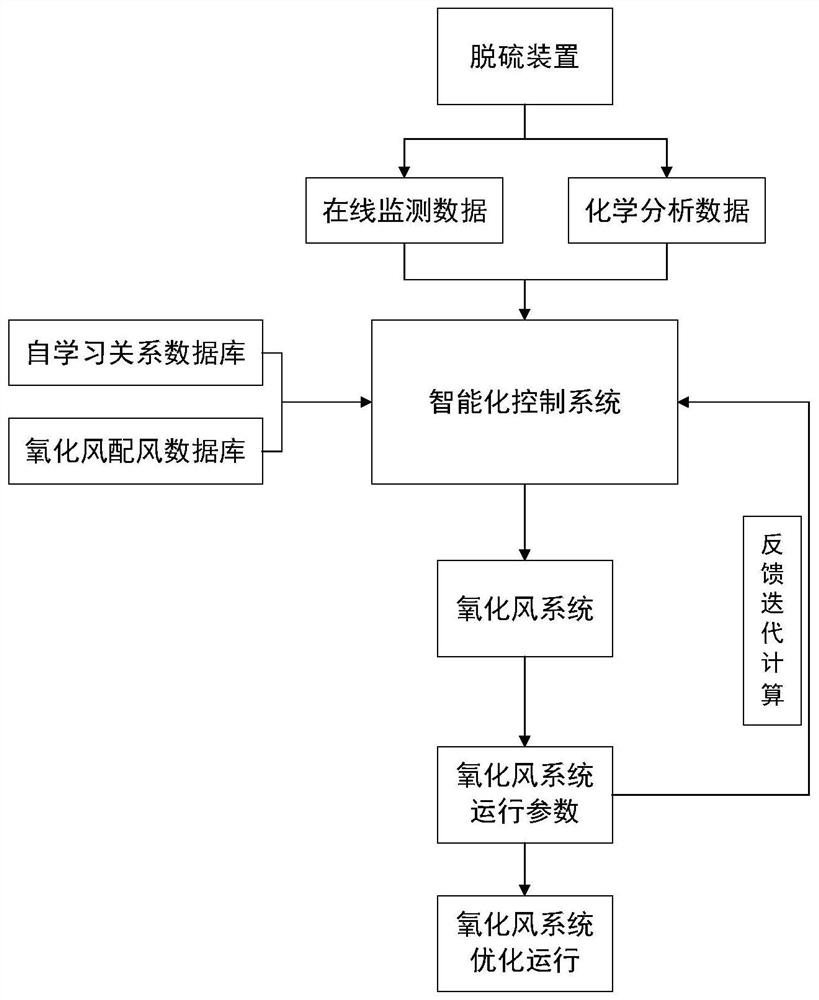

[0048] refer to Figure 1~3 , an oxidation fan operation optimization method for a single-tower double-cycle desulfurization device, the single-tower double-cycle desulfurization device includes a primary desulfurization slurry circulation system, a secondary desulfurization slurry circulation system, an oxidation air system, a flue gas system, and a demister 3. Gypsum discharge system, operating parameter monitoring system 18, intelligent control system 19, the flue gas system includes the original flue gas inlet flue 1 and the clean flue gas outlet flue 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com