Recyclable carrier and method for manufacturing embedded circuit by using same

A circuit production and carrier technology, which is applied in the fields of printed circuit manufacturing, printed circuit, electrical components, etc., can solve the problems that the carrier cannot be reused, affects product quality, and poor compatibility, so as to avoid the residue of medicine, reduce loss and compatibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] A method for fabricating embedded circuits using a recyclable carrier, comprising the following steps:

[0026] (1) Prepare the carrier, generate a conductive layer on the carrier and perform pattern plating to make the circuit; pattern plating can set and precisely control the height, width and spacing of the circuit according to requirements.

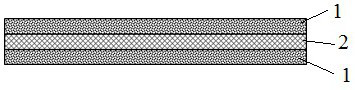

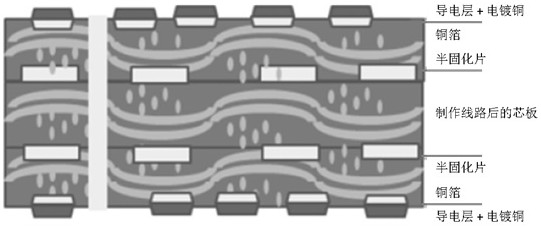

[0027] (2) Lay the obtained carrier with the circuit with the prepreg and the core board with the circuit and send it to the press for pressing;

[0028] (3) After lamination, the carrier is removed, which can be directly torn off by hand, or the carrier can be removed; the carrier and the coating are completely separated and then removed for the next round of production to realize the recycling of the carrier.

[0029] (4) After removing the carrier, drill holes; melt copper; then perform dry film pressing, pattern el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com