Small ditching, fertilizing and earthing all-in-one machine for hills and mountains

An all-in-one, mountain technology, used in fertilization devices, excavation/covering of trenches, mechanical equipment, etc., can solve the problems of clogging the soil at the fertilization outlet, unsuitable for fertilization operations in hilly and mountainous orchards, and large entry resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with drawings and embodiments.

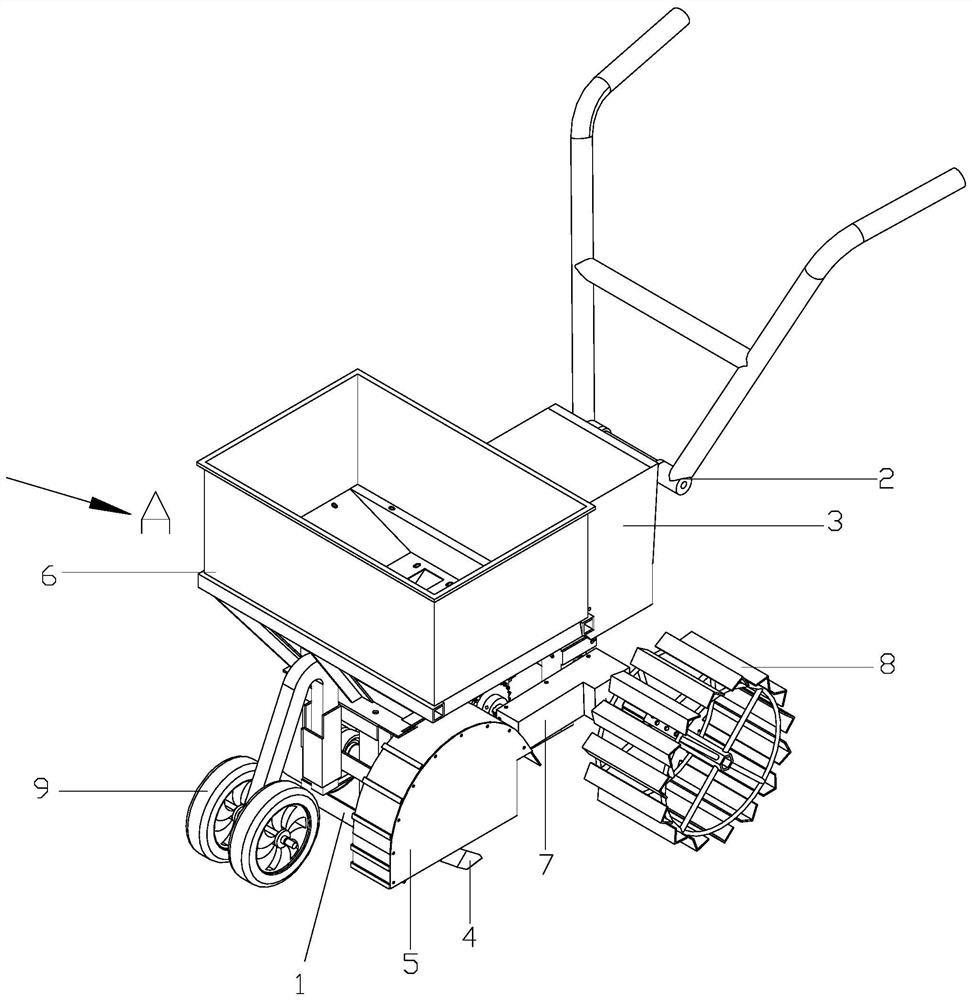

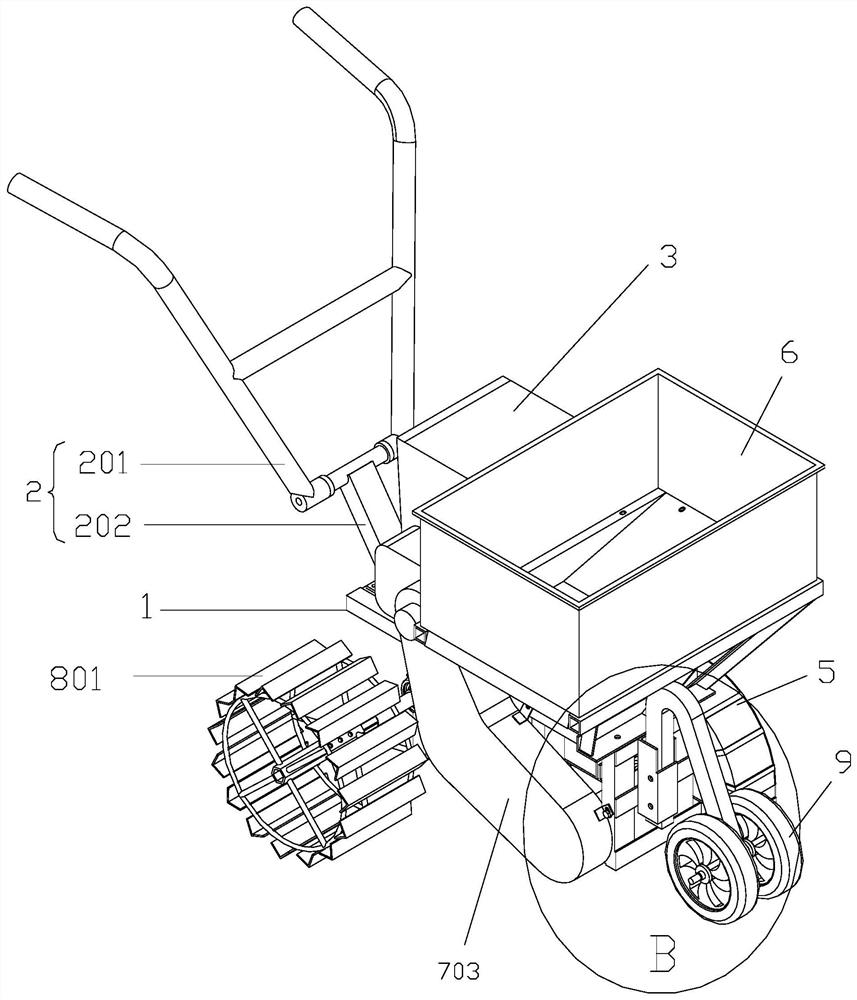

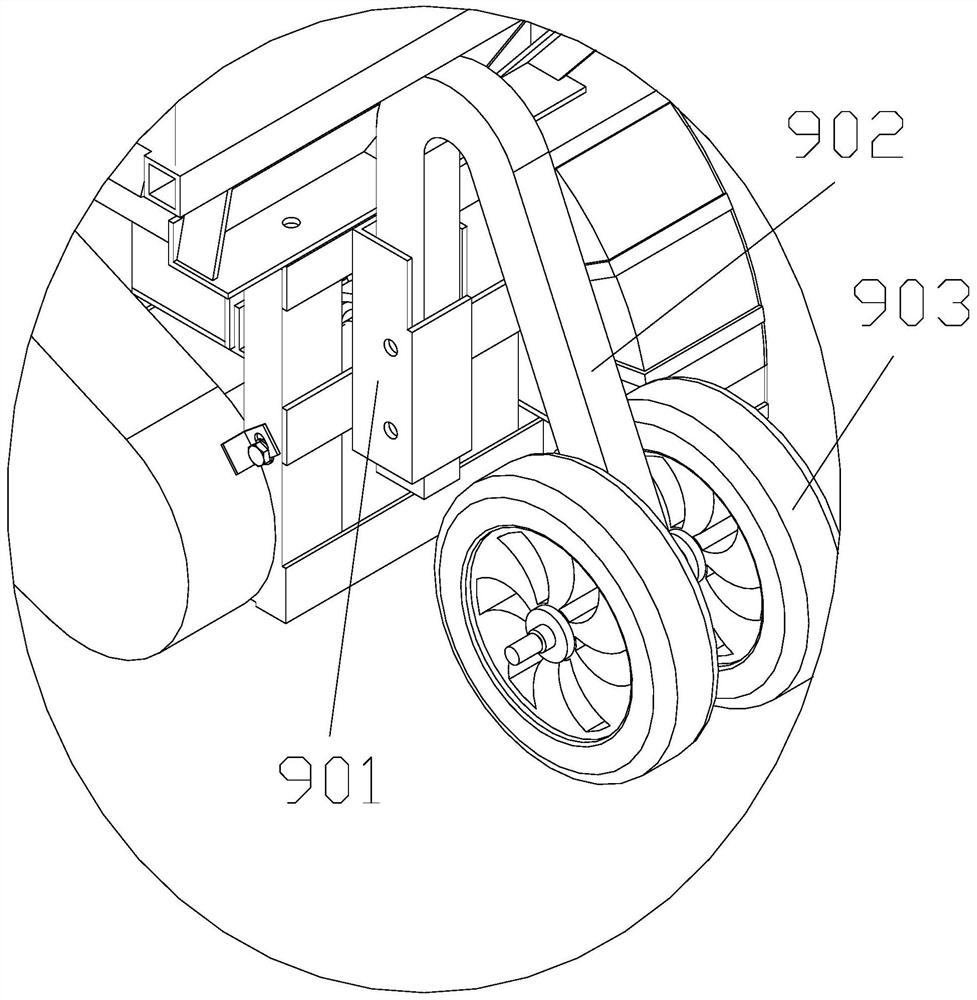

[0045] like figure 1 , figure 2 , image 3 The small-scale all-in-one machine for ditching, fertilizing and soil covering in hilly and mountainous areas shown includes frame 1, hand frame 2, engine 3, ditching knife 4, soil covering cover 5, fertilization device 6, transmission device 7, traveling device 8 and tillage depth adjustment device 9;

[0046] The armrest frame 2 includes an armrest handle 201 and an armrest fixing base 202 that are hinged to each other. The operating comfort of the whole machine can be adjusted by adjusting the connection angle of the armrest fixing base 202 and the armrest handle 201. The armrest fixing base 202 is fixedly connected to the frame 1 on the cantilever beam at the rear end of the top; the engine 3 and the fertilization device 6 are installed on the upper end of the frame 1, the ditching knife 4 is installed in the soil cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com