High-energy-density fat emulsion as well as preparation method and application thereof

A high energy density, fat emulsion technology, applied in the field of biomedicine, can solve the problems of insufficient energy density and low stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: fat emulsion preparation

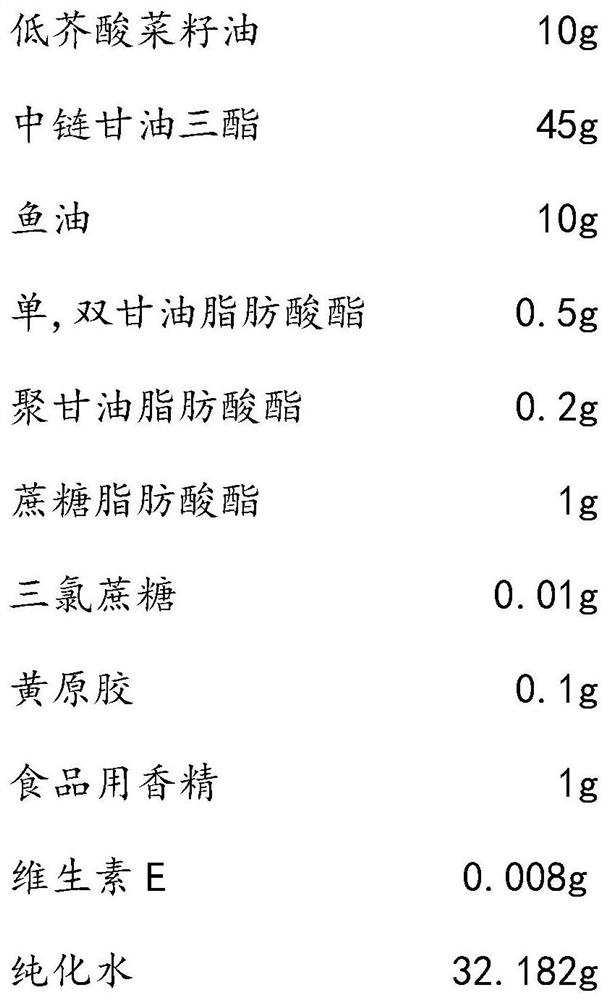

[0049] The composition of fat emulsion is:

[0050]

[0051] The preparation of fat emulsion comprises the following steps:

[0052] (1) Add sucralose, xanthan gum, and food flavors into preheated purified water, control the temperature at 60-70°C, stir at 6000r / min until completely dissolved, and obtain the aqueous phase.

[0053] (2) Add mono- and diglyceride fatty acid esters, polyglycerol fatty acid esters, sucrose fatty acid esters, and vitamin E to preheated canola oil, medium-chain triglycerides, and fish oil, and control the temperature at 60- Stir at 70°C and 10000r / min until completely dispersed to obtain an oil phase.

[0054] (3) Mix the oil phase and the water phase, and shear at a high speed of 10,000 r / min for 30 minutes to obtain colostrum; homogenize the obtained colostrum under high pressure at 60° C. and 600 bar.

[0055] (4) Fill the homogenized emulsion into a glass bottle, seal and airtight.

[0056] ...

Embodiment 2

[0057] Embodiment 2: fat emulsion preparation

[0058] The composition of fat emulsion is:

[0059]

[0060] The preparation method of fat emulsion is: comprise the following steps:

[0061] (1) Add sucralose, xanthan gum, and food flavors into preheated purified water, control the temperature at 60-70°C, stir at 6000r / min until completely dissolved, and obtain the aqueous phase.

[0062] (2) Add mono- and diglyceride fatty acid esters and tert-butyl hydroquinone to the preheated canola oil, medium-chain triglycerides and fish oil, control the temperature at 60-70°C, 10000r / min Stir until completely dispersed to obtain an oily phase.

[0063] (3) Mix the oil phase and the water phase, and shear at a high speed of 10,000 r / min for 30 minutes to obtain colostrum; homogenize the obtained colostrum under high pressure at 60° C. and 600 bar.

[0064] (4) Fill the homogenized emulsion into a glass bottle, seal and airtight.

[0065] (5) The product is sterilized in a water ba...

Embodiment 3

[0066] Embodiment 3: fat emulsion preparation

[0067] The composition of fat emulsion is:

[0068]

[0069] The preparation method of fat emulsion is: comprise the following steps:

[0070] (1) Add sucralose, sodium carboxymethylcellulose, sodium caseinate, and food flavors to preheated purified water, control the temperature at 60-70°C, stir at 6000r / min until completely dissolved, and obtain water Mutually.

[0071] (2) Add citric acid fatty acid glycerides, diacetyl tartaric acid mono-diglycerides, and tert-butyl hydroquinone to the preheated canola oil, medium-chain triglycerides, and fish oil, and control the temperature at 60- Stir at 70°C and 10000r / min until completely dispersed to obtain an oil phase.

[0072] (3) Mix the oil phase and the water phase, and shear at a high speed of 10,000 r / min for 30 minutes to obtain colostrum; homogenize the obtained colostrum under high pressure at 60° C. and 600 bar.

[0073] (4) Fill the homogenized emulsion into a glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com