Uniform and fine duplex stainless steel thin strip based on cast-rolling short process and preparation method of uniform and fine duplex stainless steel thin strip

A duplex stainless steel and short-process technology, which is applied in the field of steel material manufacturing, can solve the problems of affecting the yield, poor coordination of two-phase deformation, and limiting the total reduction of rolling, so as to shorten working hours, avoid rolling cracking, Effect of Large Rolling Deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

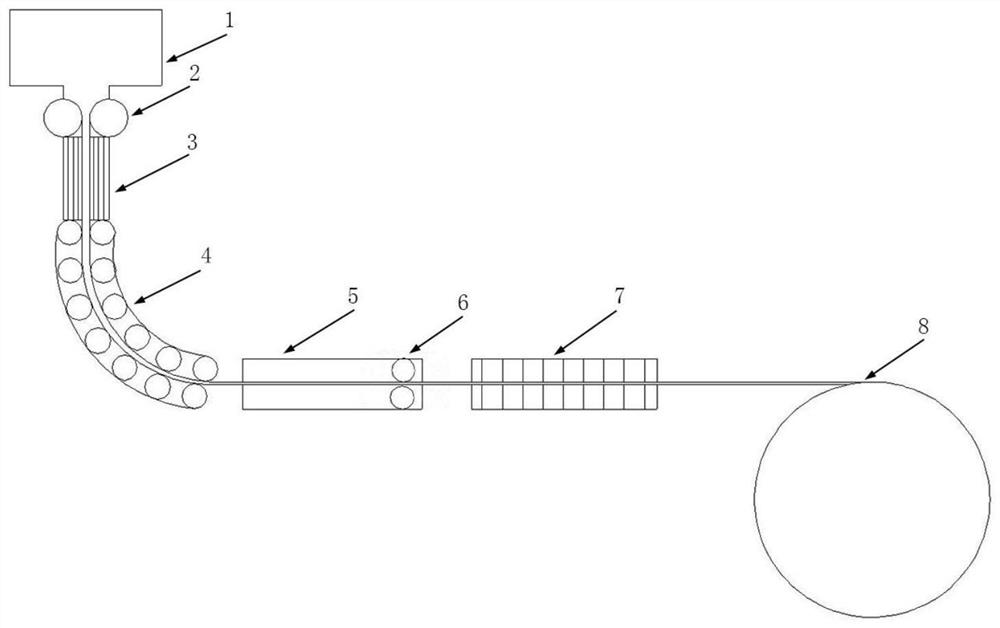

[0037] A method for preparing uniform and fine duplex stainless steel thin strips based on short casting and rolling processes, the process flow is as follows figure 1 As shown, the specific steps are as follows:

[0038] Step 1, molten steel smelting:

[0039] The composition is in accordance with the composition ratio of 2205 duplex stainless steel, that is (wt%): C: 0.06%, Si: 0.42%, Mn: 1.65%, Ni: 5.0%, Cr: 22.2%, N: 0.12%, Fe balance . Molten steel is smelted in an argon-filled, high-pressure melting furnace. Among them, argon gas is used to prevent the entry of other gases; high pressure is beneficial to improve the yield of manganese and nitrogen.

[0040] Step 2, twin roll casting:

[0041]Preheat the tundish 1, then pour molten steel into the tundish 1, and control the superheat between 50 and 80°C, which is beneficial to avoid partial solidification (crystallization) of the molten steel in the tundish, or even freezing to block the nozzle; at the same time, It c...

Embodiment 2

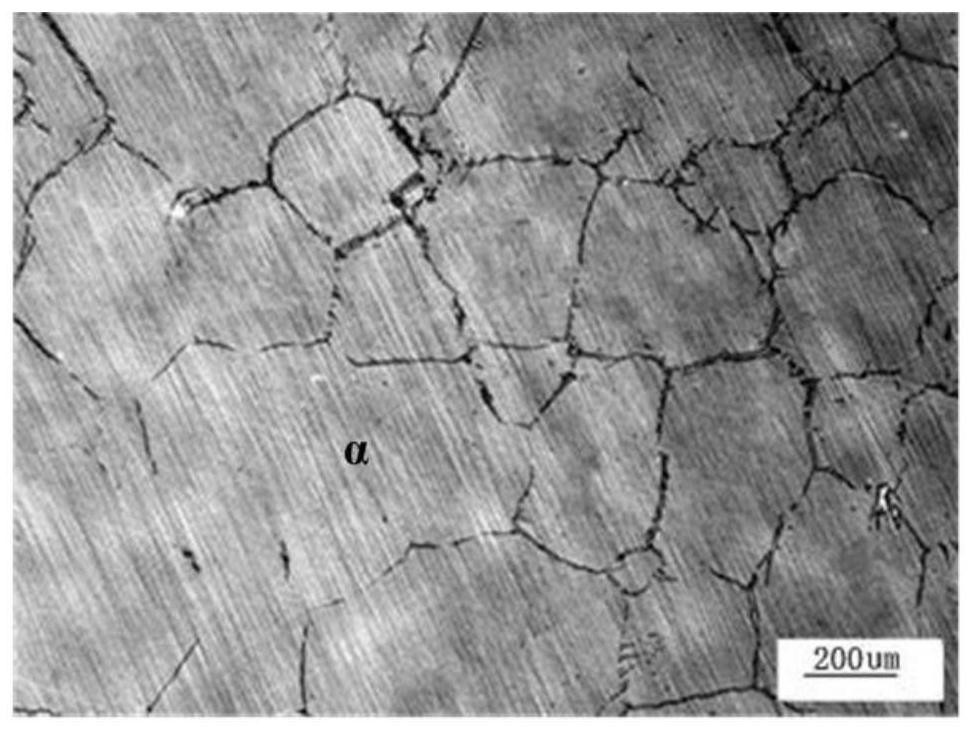

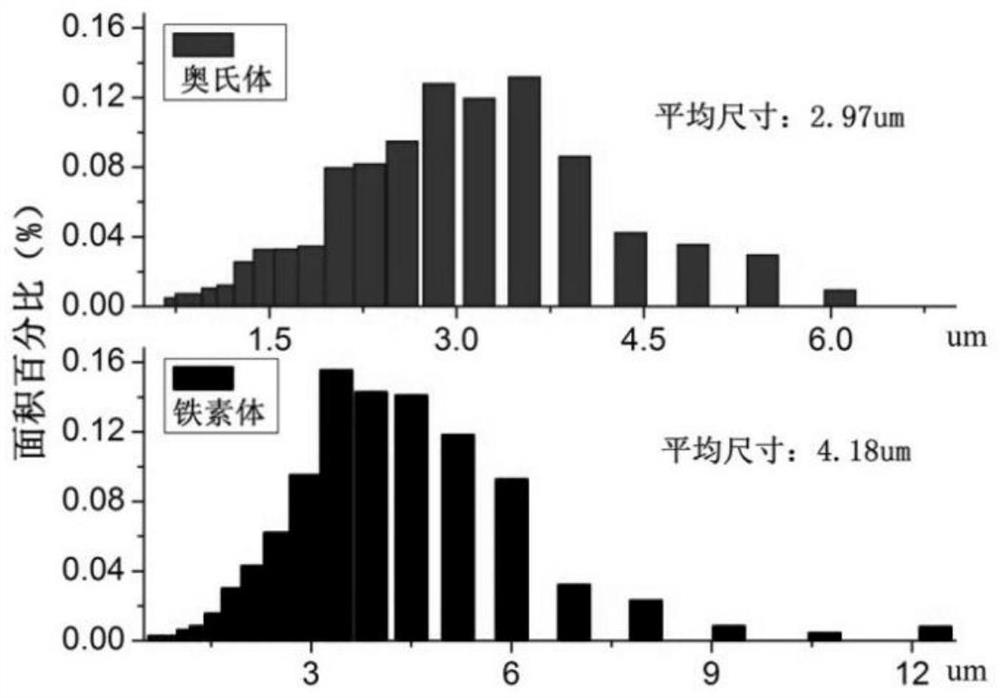

[0055] Melting molten steel, its composition ratio is (wt%): C: 0.03%, Si: 1.0%, Mn: 5.0%, Ni: 1.5%, Cr: 21.0%, N: 0.2%, Mo: 0.5%, Cu: 0.5%, Fe balance; Subsequent preparation of duplex stainless steel thin strip according to the technical process of embodiment 1, wherein the specific process parameters involved are shown in Table 1; the fine and uniform grain metallographic structure of the finished thin strip is shown in Figure 4 ; The stress-strain curve under the quasi-static tensile test is as follows Figure 7 shown.

Embodiment 3

[0057] Melting molten steel to prepare a duplex stainless steel strip with TRIP effect, its composition ratio is (wt%): C: 0.04%, Si: 1.6%, Mn: 2.9%, Ni: 2.0%, Cr: 20% , N: 0.19%, Mo: 0.5%, and the remainder of Fe; subsequently, duplex stainless steel thin strips were prepared according to the process flow of Example 1. The specific process parameters involved are shown in Table 1; the fine and uniform grain metallographic structure of the finished strip is shown in Table 1. Figure 5 ; The stress-strain curve under the quasi-static tensile test is as follows Figure 7 shown.

[0058] For ease of comparison, the following comparative examples are provided:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com