Ultrahigh-speed digital printing machine

A digital printing machine and ultra-high-speed technology, applied in the field of digital printing machines, can solve the problems of low production efficiency of digital printing machines, affecting the printing accuracy of digital printing machines, difficult printing accuracy, etc., to improve printing efficiency, small size, and improve precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

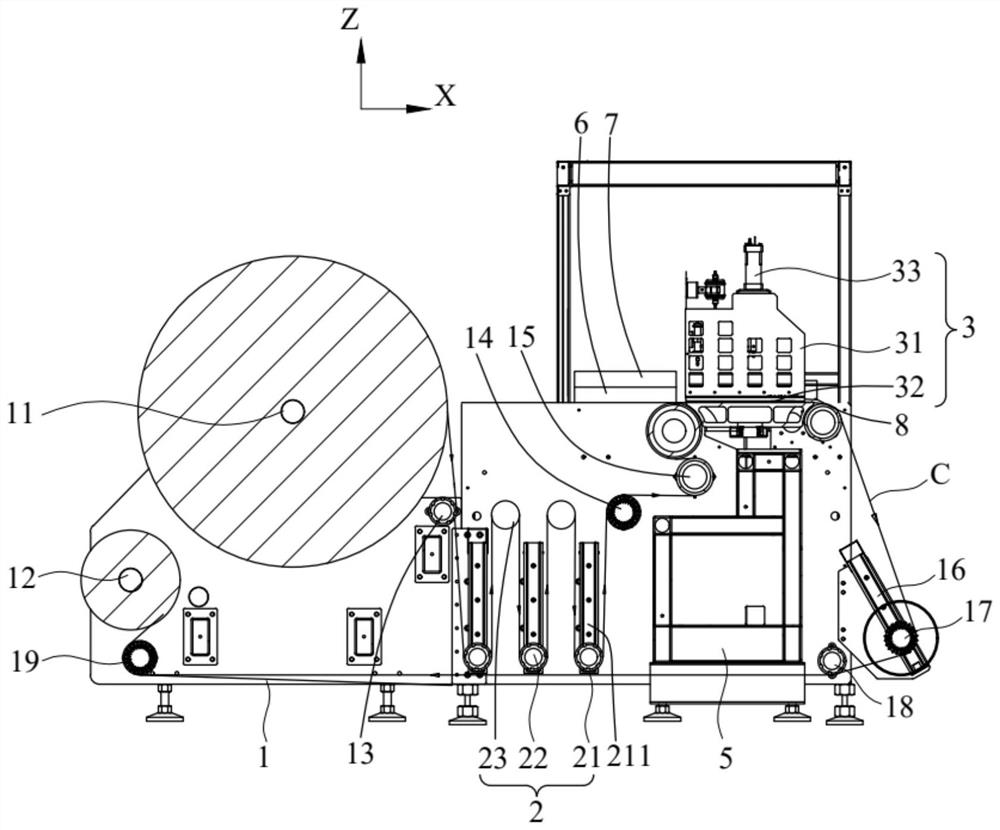

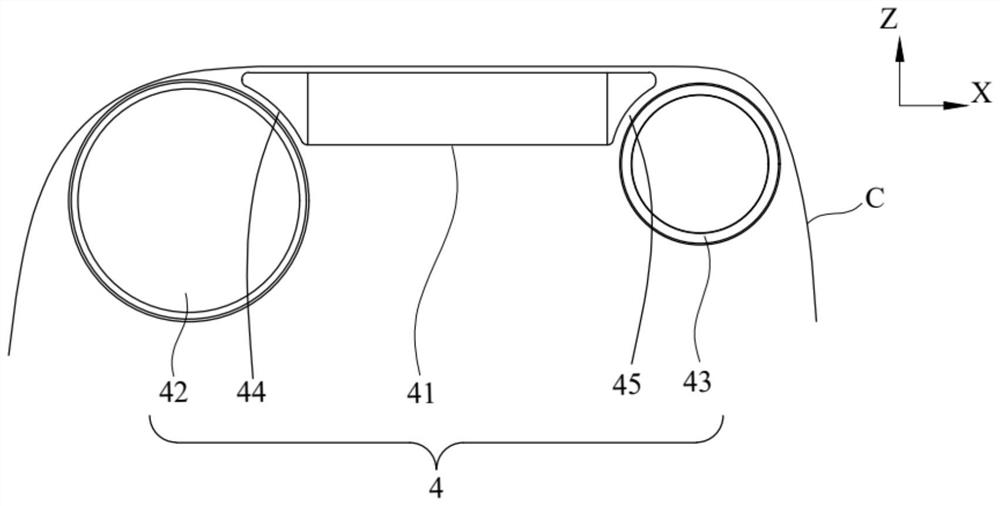

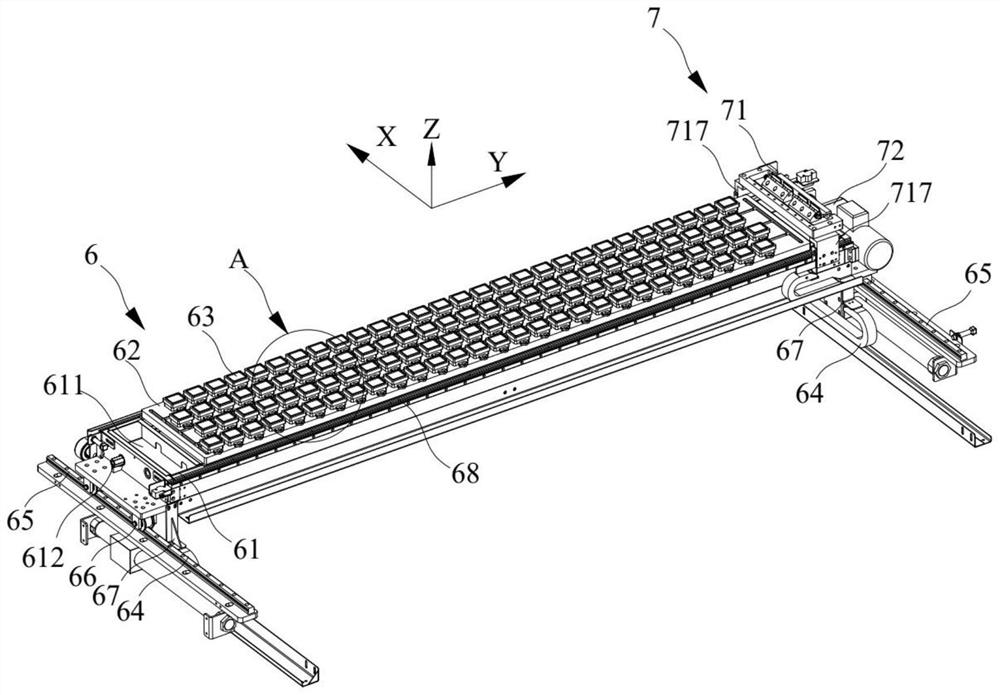

[0051] Such as figure 1 with 2 As shown, the embodiment of the present invention provides an ultra-high-speed digital printing machine. The ultra-high-speed digital printing machine in the embodiment of the present invention is mainly used for printing on roll media, and the medium C can be paper, cloth or other printable plastic materials. , the medium C is not limited to the materials described above, the ultra-high-speed digital printing machine of the embodiment of the present invention includes: a frame 1; preferably, the frame 1 is a marble frame, the structure of the marble is uniform, and the coefficient of linear expansion is It is extremely small, the internal stress completely disappears, and has the characteristics of no deformation, good rigidity, high hardness, and strong wear resistance. When applied to frame 1, frame 1 has good stress. From a technical point of view, the marble frame can solve At present, the problem of the accuracy of the frame of the steel s...

Embodiment 2

[0070] Such as Figure 8 As shown, the embodiment of the present invention is based on the first embodiment. The embodiment of the present invention provides an ultra-high-speed digital printing machine, and a second constant tension roller is arranged between the winding mechanism and the drying mechanism 5 Agency113. The second constant tension roller mechanism 113 can further keep the medium C in a constant tension state, and the principle of the second constant tension roller mechanism 113 is the same as that of the first constant tension roller mechanism 2, so it will not be redundant here, so A fourth corner roller 110 for corners and a fourth brush roller 111 for preventing wrinkles are also arranged between the second constant tension roller mechanism 113 and the drying mechanism 5, the fourth corner roller 110 and the The fourth brush roller 111 is rotatably arranged on the frame 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com