Cathode electrophoretic coating containing anti-shrinkage agent and preparation method thereof

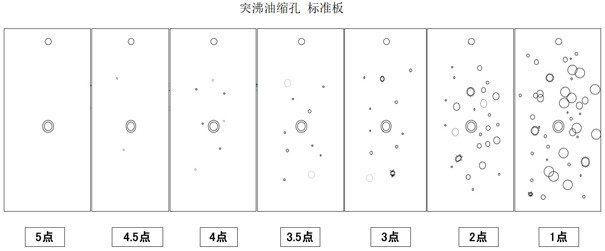

A cathodic electrophoretic coating and shrinkage crater technology, which is applied in electrophoretic coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor film leveling, large differences in surface tension, and large usage of electrophoretic coatings. , to achieve the effect of uniform and stable emulsion, low cost and small addition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of a cathodic electrophoretic coating containing an anti-cratering agent, comprising the following steps:

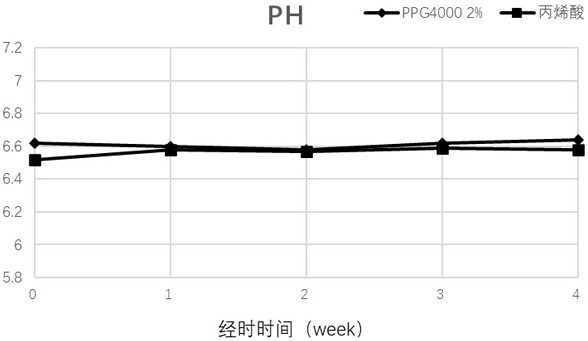

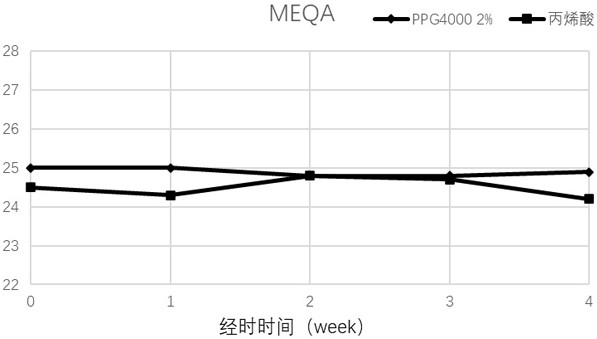

[0033] (1) Preparation of emulsion

[0034] 40 parts by mass of low-molecular-weight epoxy resin and 20 parts by mass of bisphenol A were reacted for chain extension at 140°C under the catalysis of 0.08 parts by mass of triphenylphosphine for 4 hours, and then 7 parts by mass of diethanolamine was added after the temperature was lowered to 100°C Rise to 115°C and react for 1 hour, then add 32 parts by mass of blocked polyisocyanate compound and 1 part by mass of PPG4000 to react at 80°C for 0.5 hours, and obtain a dispersed resin after cooling, after neutralizing 100 parts by mass of dispersed resin with 5 parts by mass of acetic acid Add 200 parts by mass of water for emulsification under high-speed stirring to prepare an emulsion.

[0035] (2) Preparation of cathodic electrophoretic coating

[0036] Mix the emulsion obtained in step (1) wi...

Embodiment 2

[0039] The only difference from Example 1 is that the amount of PPG4000 added is 2 parts.

Embodiment 3

[0050] The only difference from Example 1 is that the anti-cratering agent is PPG1000, and the addition amount is 0.5 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com