Quantum dot loaded conjugated microporous polymers and preparation method thereof, quantum dot diaphragm and liquid crystal display module

A technology of liquid crystal display modules and conjugated micropores, which is applied in the direction of film/sheet without carrier, non-polymer organic compound adhesives, chemical instruments and methods, etc., which can solve the problem of easy agglomeration of quantum dots and reduce the use of quantum dots Quantity and other issues, to achieve the effect of simple process, reduce the actual usage, and improve the uniformity of color coordinates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

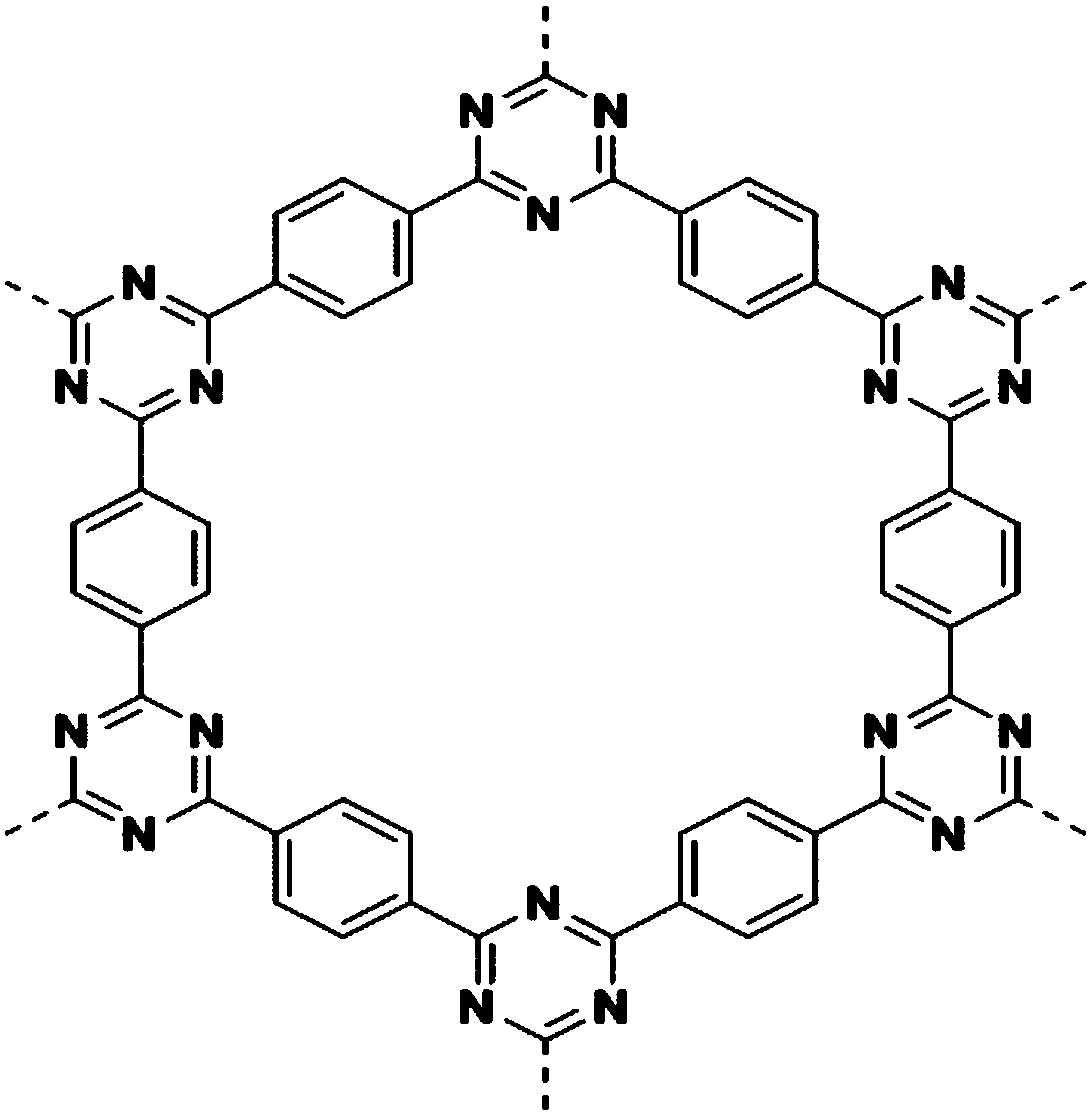

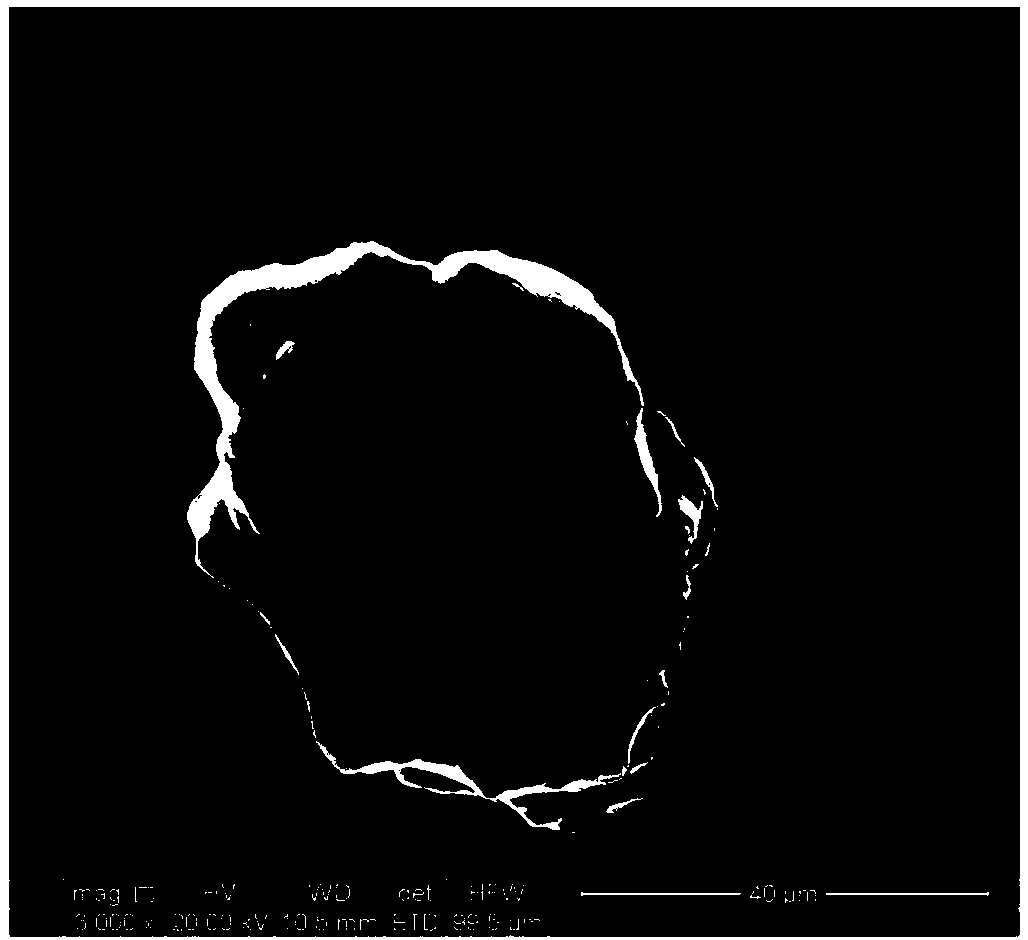

[0055] The preparation method of the conjugated microporous polymer loaded with quantum dots provided by the invention comprises the following steps:

[0056] (1) Preparation of conjugated microporous polymer (CMP): Mix 1,4-dicyanobenzene and zinc chloride powder evenly and put them into a quartz tube, then vacuumize the quartz tube, melt and seal it, and place Heat in a tube furnace at 200-1200°C for 20-80 hours under a nitrogen atmosphere. After cooling to room temperature, take out the powder in the quartz tube, and obtain the desired conjugated microporous polymer CMP after filtration, washing, and Soxhlet extraction;

[0057] (2) Preparation of conjugated microporous polymers loaded with quantum dots: fully stir and mix the quantum dot dispersion liquid and conjugated microporous polymers, and then encapsulate the above-mentioned mixed slurry into polytetrafluoroethylene hydrothermal reaction Kettle, and placed in a high-temperature oven at 40-100 ° C for 12 hours. Afte...

Embodiment 1

[0075] 1. Preparation of conjugated microporous polymer (CMP)

[0076] Mix 1,4-dicyanobenzene (128g, 1mol) and zinc chloride powder (13.6g, 0.1mol) evenly and put them into a quartz tube, then vacuumize the quartz tube, melt and seal it, and place it in a tube The furnace was heated at 600° C. for 40 hours under a nitrogen atmosphere. After cooling to room temperature, the powder in the quartz tube was taken out, and the desired conjugated microporous polymer CMP was obtained after suction filtration, washing, and Soxhlet extraction, with a yield of 94%.

[0077] 2. Preparation of conjugated microporous polymer (QD-CMP) loaded with quantum dots

[0078] With 42.6g 15wt% green cadmium selenide quantum dot dispersion liquid (green cadmium selenide consumption is 6.4g), 42.6g15wt% red cadmium selenide quantum dot dispersion liquid (red cadmium selenide consumption is 6.4g) and above-mentioned 12.8g altogether The yoke microporous polymer CMP was fully stirred and mixed, and the...

Embodiment 2

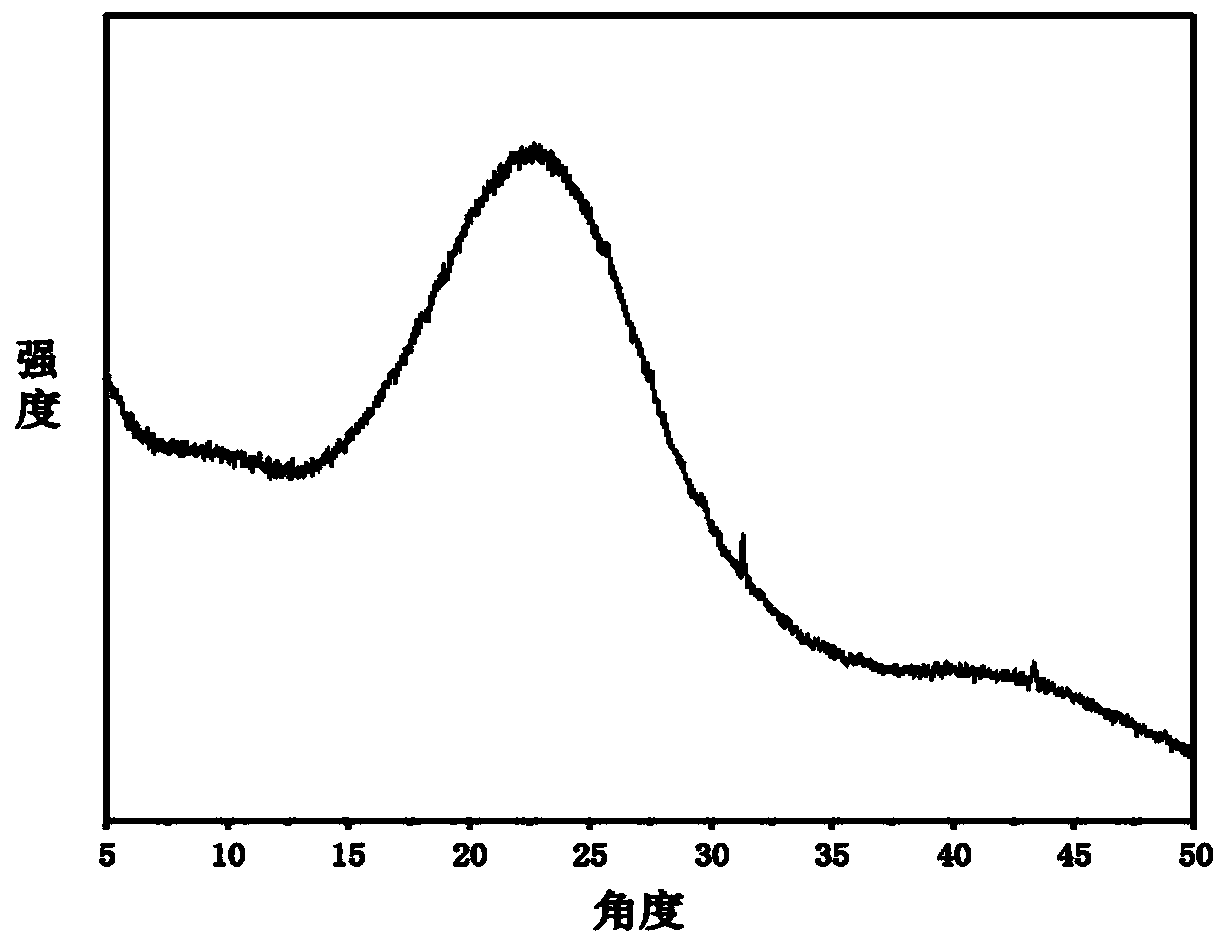

[0081] As the conjugated microporous polymer provided in Example 1 and the conjugated microporous polymer loaded with quantum dots, in the preparation of the conjugated microporous polymer (CMP), 1,4-dicyanobenzene (128g, 1mol), zinc chloride powder (272g, 2mol) were mixed evenly and packed into a quartz tube.

[0082] Table 1 shows the performance test results of the prepared conjugated microporous polymer and the conjugated microporous polymer loaded with quantum dots.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com