Multi-walled carbon nanotube/metal organic framework composite material and preparation method thereof

A technology of multi-walled carbon nanotubes and metal organic frameworks, which is applied in chemical instruments and methods, other chemical processes, adsorption water/sewage treatment, etc. Adsorption performance, increased use of MOFs, etc., to achieve the effect of simple treatment process and adsorption equipment, high application value and commercial value, and fast adsorption speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

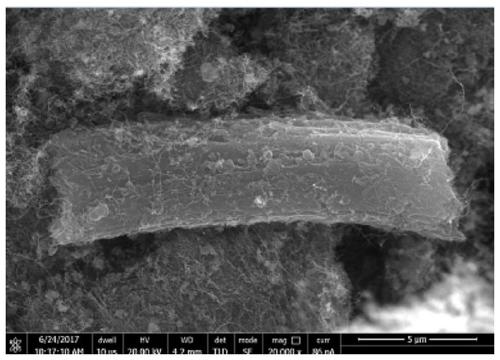

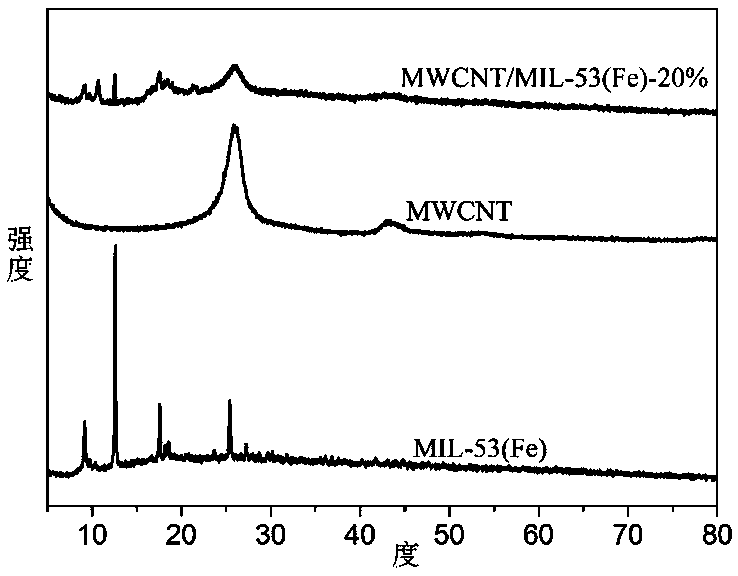

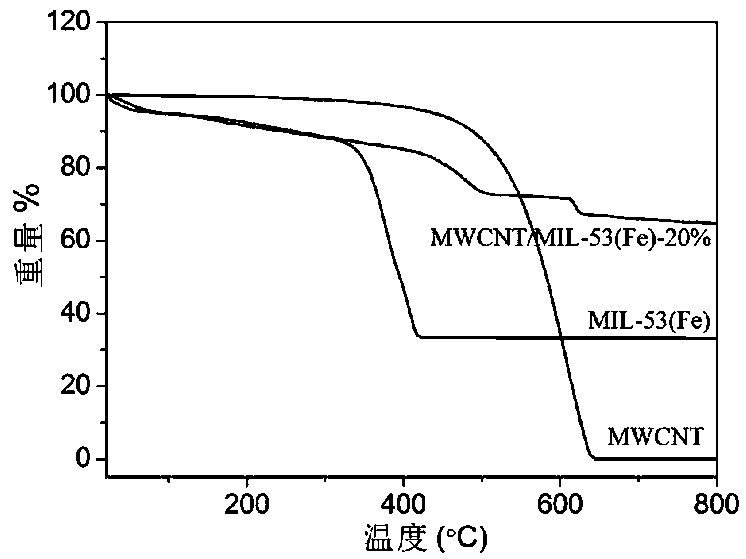

[0036] A multi-walled carbon nanotube / metal-organic framework composite material comprising multi-walled carbon nanotubes and MIL-53(Fe), wherein the multi-walled carbon nanotubes are doped in the MIL-53(Fe).

[0037] In this embodiment, the mass ratio of multi-walled carbon nanotubes to MIL-53(Fe) is 0.2.

[0038] A method for preparing the multi-walled carbon nanotube / metal-organic framework composite material of the present embodiment, comprising the following steps:

[0039] (1) Put 2g of unmodified multi-walled carbon nanotubes into 100mL of a mixed solution of concentrated sulfuric acid and concentrated nitric acid (the volume ratio of concentrated sulfuric acid and concentrated nitric acid in the mixed solution is 1:3), at 70°C, Stir at 400 r / min for 24 h, modify the multi-walled carbon nanotubes, wash the modified multi-walled carbon nanotubes with deionized water for 6 times, and dry at 70 °C for 10 h to obtain the modified multi-walled carbon nanotubes Tube.

[004...

Embodiment 2

[0047] A multi-walled carbon nanotube / metal-organic framework composite material, which is basically the same as the multi-walled carbon nanotube / metal-organic framework composite material in Example 1, the difference being: the multi-walled carbon nanotube and MIL in Example 2 The mass ratio of -53(Fe) is 0.01.

[0048] A preparation method of the multi-walled carbon nanotube / metal-organic framework composite material of the above-mentioned embodiment is basically the same as the preparation method in Example 1, except that: in step (2) of Example 2, more The amount of walled carbon nanotubes used is 0.0109 g.

[0049] The multi-walled carbon nanotube / metal organic framework composite material (MWCNT / MIL-53(Fe)) prepared in Example 2 is labeled as MWCNT / MIL-53(Fe)-1%.

Embodiment 3

[0051] A multi-walled carbon nanotube / metal-organic framework composite material, which is basically the same as the multi-walled carbon nanotube / metal-organic framework composite material in Example 1, the difference being: the multi-walled carbon nanotube and MIL in Example 3 The mass ratio of -53(Fe) was 0.05.

[0052] A method for preparing the multi-walled carbon nanotube / metal-organic framework composite material of the above-mentioned embodiment is basically the same as the preparation method in Example 1, except that: in step (2) of Example 3, more The amount of walled carbon nanotubes used is 0.0545 g.

[0053] The multi-walled carbon nanotube / metal organic framework composite material (MWCNT / MIL-53(Fe)) prepared in Example 3 is labeled as MWCNT / MIL-53(Fe)-5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com