Preparation method of zirconium cladding protective coating

A technology of protective coating and zirconium cladding, which is applied in the field of preparation of zirconium cladding protective coating, can solve the problems of non-wear-resistant Cr coating, weak combination of Cr coating and zirconium alloy substrate surface, etc., and achieve comprehensive performance improvement , Excellent resistance to high temperature water vapor oxidation, and the effect of reducing the oxidation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

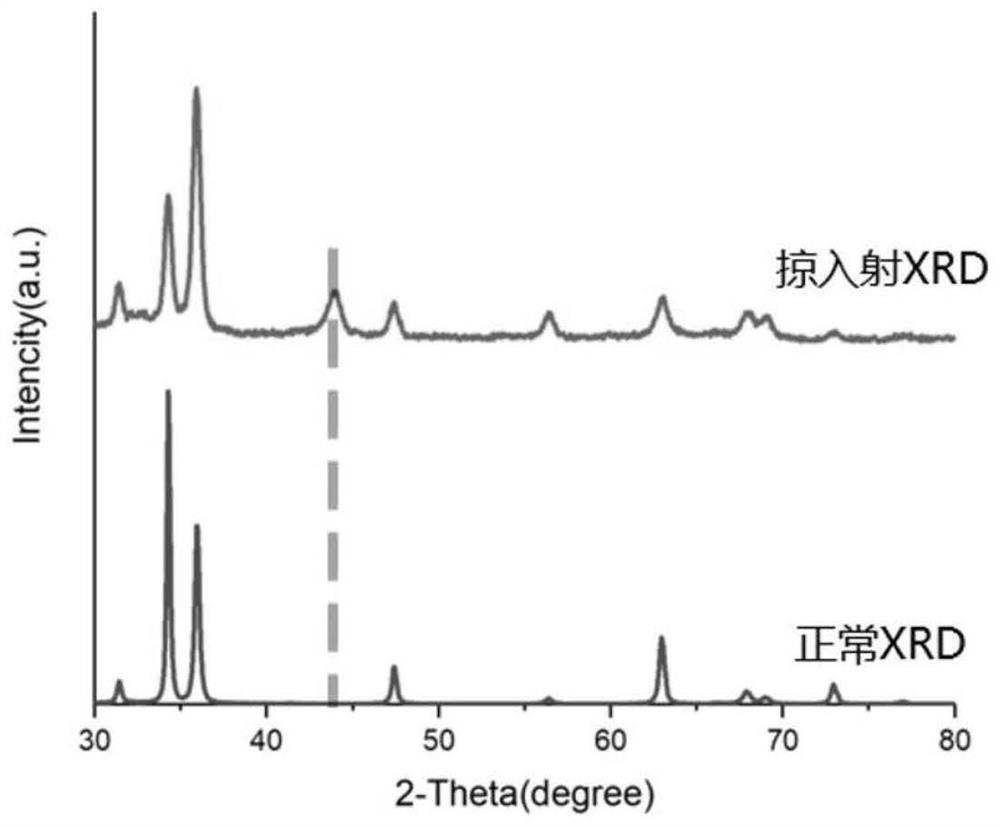

Image

Examples

specific Embodiment approach 1

[0024] (1) Preparation of functional metal layer Cr coating

[0025] Using magnetron sputtering technology, using chromium target as the target material, the vacuum degree of the background is 5×10 -4 Pa, Ar gas is the working gas, the sputtering power is 150W, the sputtering time is 45min, and the sputtering pressure is 0.5Pa, the functional metal layer Cr coating is plated on the zirconium alloy shell, and the diameter of the chromium target The size is 50 mm, the target distance is 150 mm, and the gas flow rate of argon is 20 sccm.

[0026] (2) Preparation of protective layer

[0027] Place the zirconium alloy tube shell coated with Cr coating in the deposition chamber of the atomic layer deposition instrument, and pump the deposition chamber to 5×10 -3 Torr, then inject nitrogen with a purity of 99.99% to the chamber pressure of 0.15Torr, the temperature in the deposition chamber is 150°C, and repeat 230 atomic layer deposition growth cycles to obtain ZrO 2 film layer, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap