Double-booster-pump system of precise machine room air conditioner

A computer room air conditioner and booster pump technology, applied in air conditioning systems, space heating and ventilation, household heating, etc., can solve problems such as increased energy consumption of air conditioners, poor cooling effect of air conditioners, and reduced operating efficiency of air conditioners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

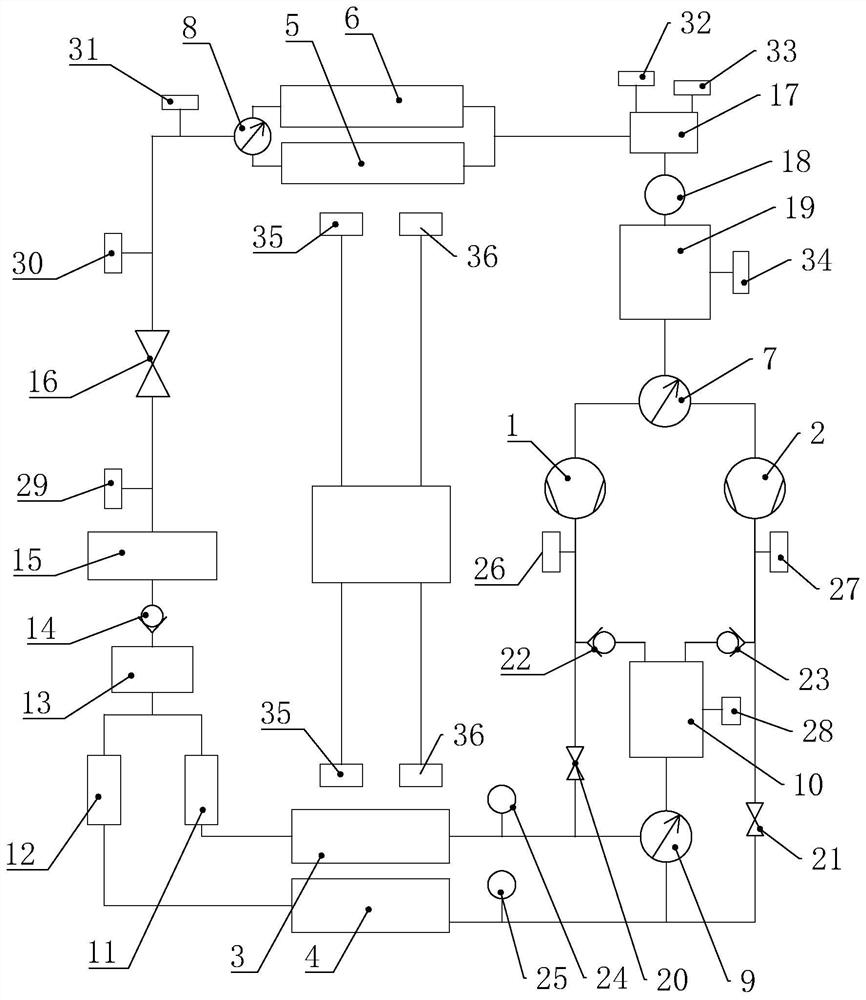

[0025] Embodiment 2. On the basis of Embodiment 1, the valve assembly further includes a first high-pressure regulating valve 20 disposed between the first booster pump 1 and the first condenser module 3, and a first high-pressure regulating valve 20 disposed between the second booster pump The second high-pressure regulating valve 21 between the pressure pump 2 and the second condenser module 4 and the first controllable check valve 22 and the second controllable check valve 22 respectively arranged on the two input ends of the pressure-stabilizing air storage tank 10 Valve 23; the sensor assembly includes a first pressure sensor 24 disposed between the first high pressure regulating valve 20 and the first condenser module 3, and a first pressure sensor 24 disposed between the first high pressure regulating valve 20 and the second condenser module 4 The second pressure sensor 25 between them, the third pressure sensor 26 and the fourth pressure sensor 27 respectively arranged ...

Embodiment 4

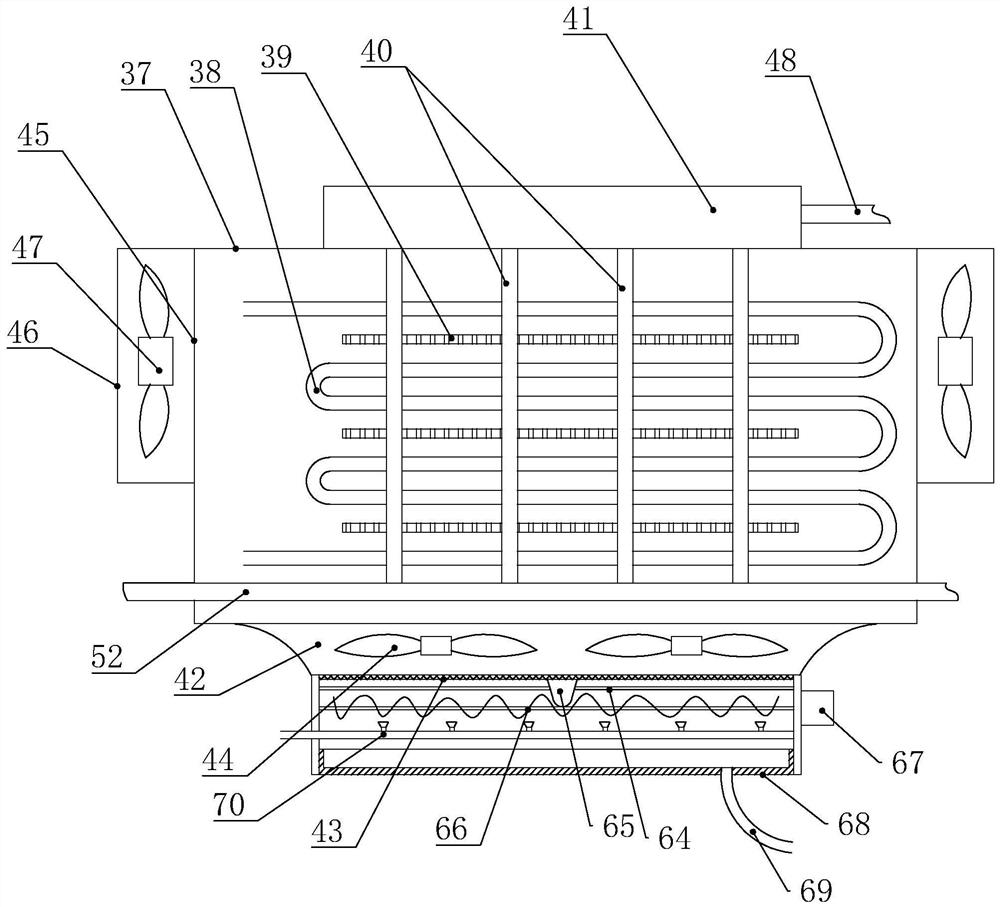

[0029] Embodiment 4: On the basis of Embodiment 3, a cleaning device and a spray device 70 are provided below the filter screen 43, and the cleaning device includes a guide rod 64 that is horizontally arranged below the filter screen 43, and the sliding connection on the guide rod 64 is useful. The brush head 65 used to clean the filter screen 43, the screw shaft 66 that drives the brush head 65 to move left and right, the screw shaft 66 is provided with a helical blade, and one end of the screw shaft 66 is connected with a driving motor 67, and the screw shaft 66 is provided below The water receiving tray 68 is connected with a sewage discharge pipe 69 at the bottom of the water receiving tray 68 . Water can be sprayed on the filter screen 43 through the spraying device 70, and the temperature of the air inlet 42 can be cooled while the filter screen 43 is cleaned, so that the temperature of the incoming air can be reduced by 1-2 degrees, which greatly improves the internal co...

Embodiment 6

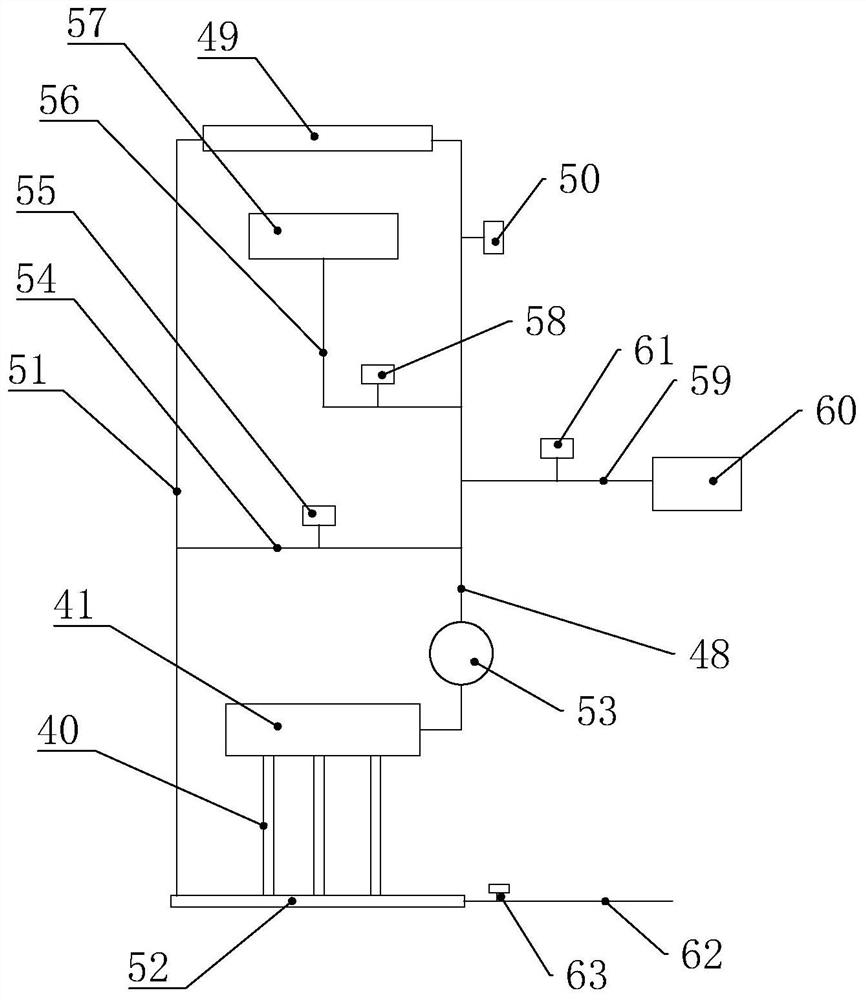

[0032] Embodiment 6: On the basis of Embodiment 5, a third water pipe 54 is provided between the first water pipe 48 and the second water pipe 51 , and a second electric control water valve 55 is provided on the third water pipe 54 . When the first electronically controlled water valve 50 is closed and the second electronically controlled water valve 55 is opened, a short water cycle can be constructed to improve heat exchange efficiency and enhance water cooling or water heating functions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com