Permanent magnetic ferrite magnetic powder for dry pressing and preparation method thereof

A technology of permanent magnet ferrite and dry pressing, which is applied in the manufacture of inductors/transformers/magnets, magnetic objects, and magnetic materials. Relative orientation degree and density, effect of improving dispersion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

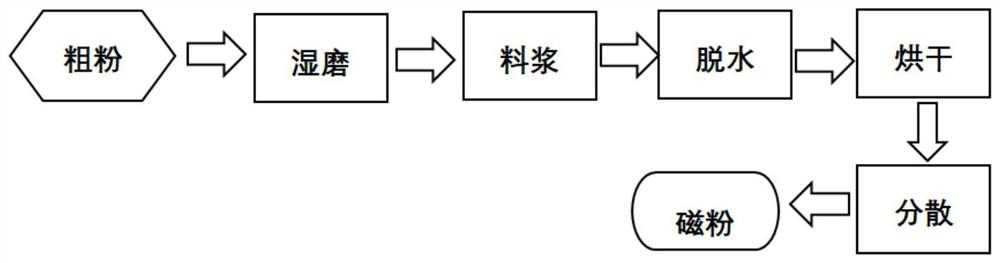

[0044] Such as Figure 4 As shown, the preparation method of the permanent ferrite magnetic powder for dry pressing of the present embodiment comprises the following steps:

[0045] (1) Preparation of coarse powder

[0046] Iron red and strontium carbonate were mixed according to the molar ratio (Fe 2 o 3 with SrCO 3 molar ratio) 5.90:1 for batching, adding 0.15wt% silicon dioxide based on the weight of iron red, mixing evenly, making pellets, pre-burning at 1295 ° C, and keeping warm for 60 minutes to obtain pre-fired pellets; after cooling , coarsely crushing the calcined balls to obtain a coarse powder with an average particle diameter of 3-6 microns.

[0047] (2) fine grinding

[0048] Based on the weight of the coarse powder, add 1.20wt% calcium carbonate, 0.25wt% silicon oxide, 0.15wt% boric acid and 0.10wt% iron red; then add a ball mill, add water and ball mill until the average particle size is 0.80 microns to obtain a slurry. The pH of the slurry was measured to ...

Embodiment 6

[0061] The preparation method of the permanent ferrite magnetic powder for dry pressing of the present embodiment comprises the following steps:

[0062] (1) Preparation of coarse powder

[0063] Using iron red, strontium carbonate, lanthanum oxide and cobalt oxide as raw materials, according to Sr 0.8 La 0.2 Fe 11.67 co 0.13 o 19 For batching, add 0.10wt% silicon dioxide based on the weight of iron red, mix evenly, pelletize, pre-fire at 1285°C, and keep warm for 60 minutes to obtain pre-fired balls; after cooling, pre-fired balls Coarse crushing to obtain a coarse powder with an average particle size of 3-6 microns.

[0064] (2) fine grinding

[0065] Based on the weight of the coarse powder, add 1.0wt% calcium carbonate, 0.25wt% silicon oxide, 0.10wt% boric acid and 0.10wt% iron red; then add a ball mill, add water and ball mill until the average particle size is 0.79 microns to obtain a slurry. The pH of the slurry was measured to be 10.6.

[0066] (3) pH adjustmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com