Lubricant oil composition for internal combustion engines and method for producing same, and method for preventing pre-ignition

A lubricating oil composition, a technology of pre-ignition, applied in the directions of lubricating composition, petroleum industry, additives, etc., can solve problems such as adverse effects of increasing fuel consumption, engine failure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5、 comparative example 1~9

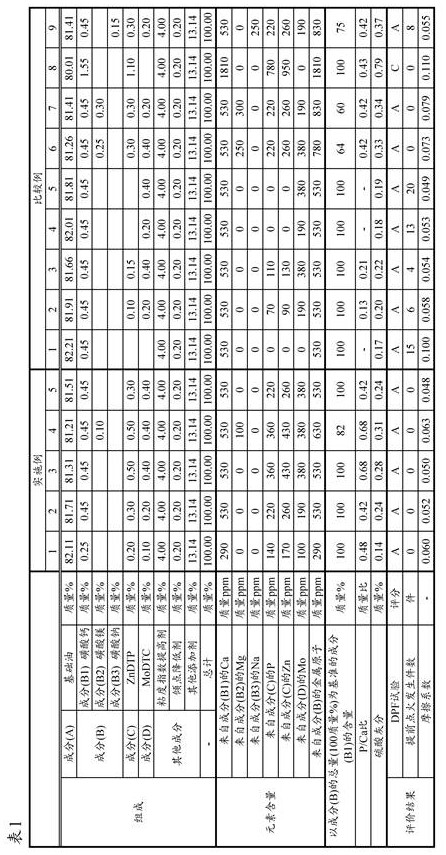

[0257] The base oils and various additives shown below were added in the blending amounts shown in Table 1, followed by sufficient mixing to prepare lubricating oil compositions. It should be noted that the dynamic viscosity of the lubricating oil composition at 100°C was adjusted to 7.8mm 2 / s.

[0258] Details of base oils and various additives used in Examples and Comparative Examples are shown below.

[0259] (ingredient (A))

[0260] ・"Base oil": Base oil classified as Group 3 in the API base oil category, dynamic viscosity at 40°C = 20.0mm 2 / s, 100℃ dynamic viscosity=4.5mm 2 / s, viscosity index=123.

[0261] (ingredient (B))

[0262] ・Component (B1) Calcium sulfonate: Calcium sulfonate, alkali value 300 mgKOH / g, calcium atom content = 11.7% by mass.

[0263] ・Component (B2) Magnesium sulfonate: Magnesium sulfonate, base value 400 mgKOH / g, content of magnesium atoms = 9.7% by mass.

[0264] ・Component (B3) Sodium sulfonate: Sodium sulfonate, base value 450 mgKOH / g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com