Stubble cutting and soil covering type spatial layering fertilization device

A layered fertilization and stubble cutting technology, which is applied in the direction of fertilization devices, cutters, fertilizer distributors, etc., can solve the problems of fertilizer loss, waste, and lower fertilizer utilization rate, so as to facilitate absorption and utilization, improve utilization rate, and promote obvious layered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings.

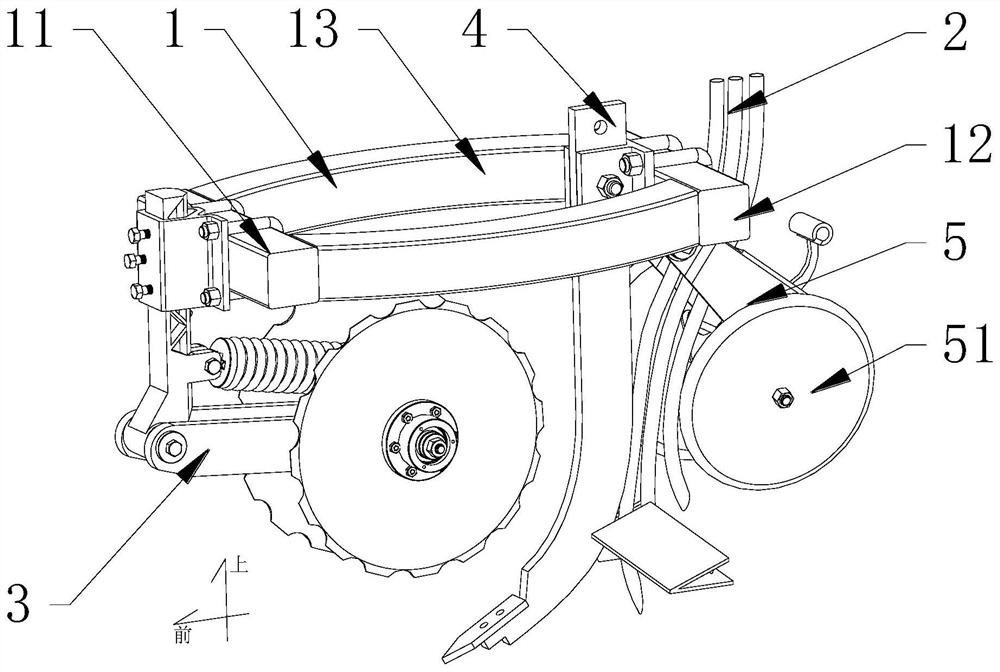

[0031] Such asfigure 1 The illustrated embodiment of the present invention includes: a fertilization tube group 2 and a double-disc stubble cutting mechanism 3, a layered fertilization shovel 4 and a side broken soil suppression mechanism 5, which are sequentially arranged under the beam group member 1 from front to back; Wherein the fertilization pipe group 2 is connected with the top fertilizer supply device (not shown in the figure), the fertilization pipe group 2 passes through the side crushing mechanism, and the outlet group of the fertilization pipe group 2 is arranged on the layered fertilization shovel and the side crushing mechanism. Between the broken soil suppression wheels 54 of the soil suppression mechanism;

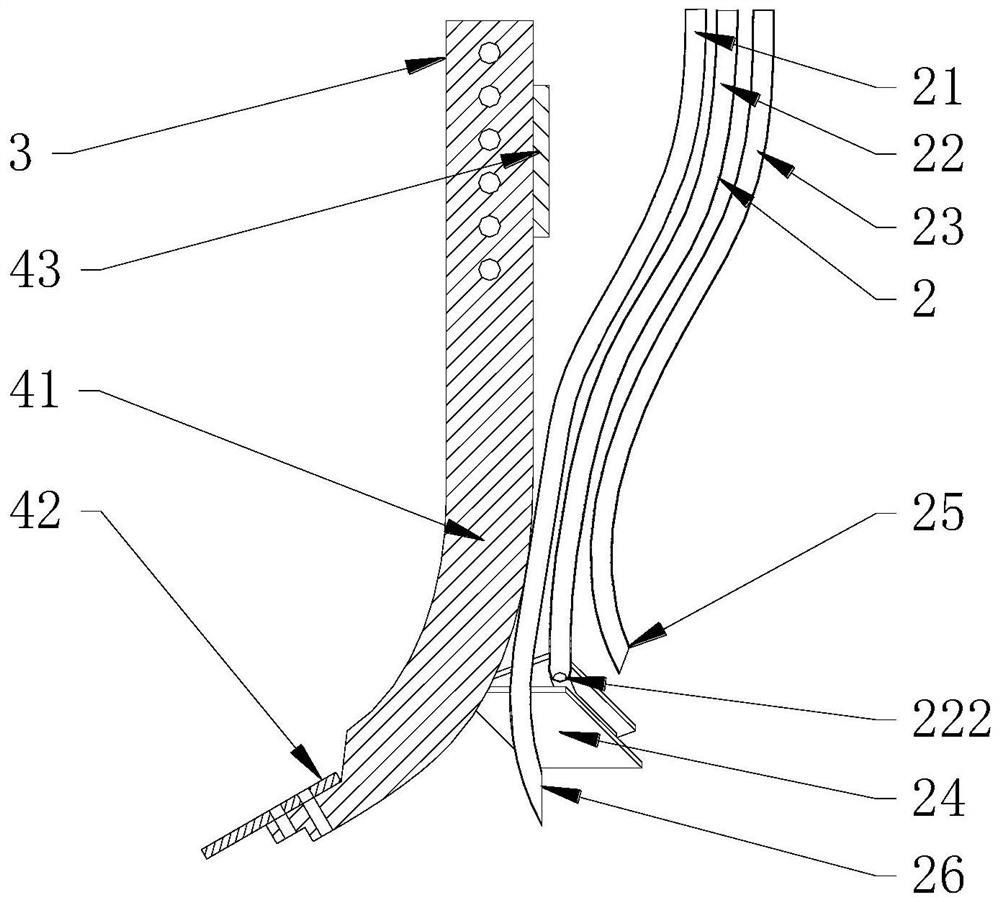

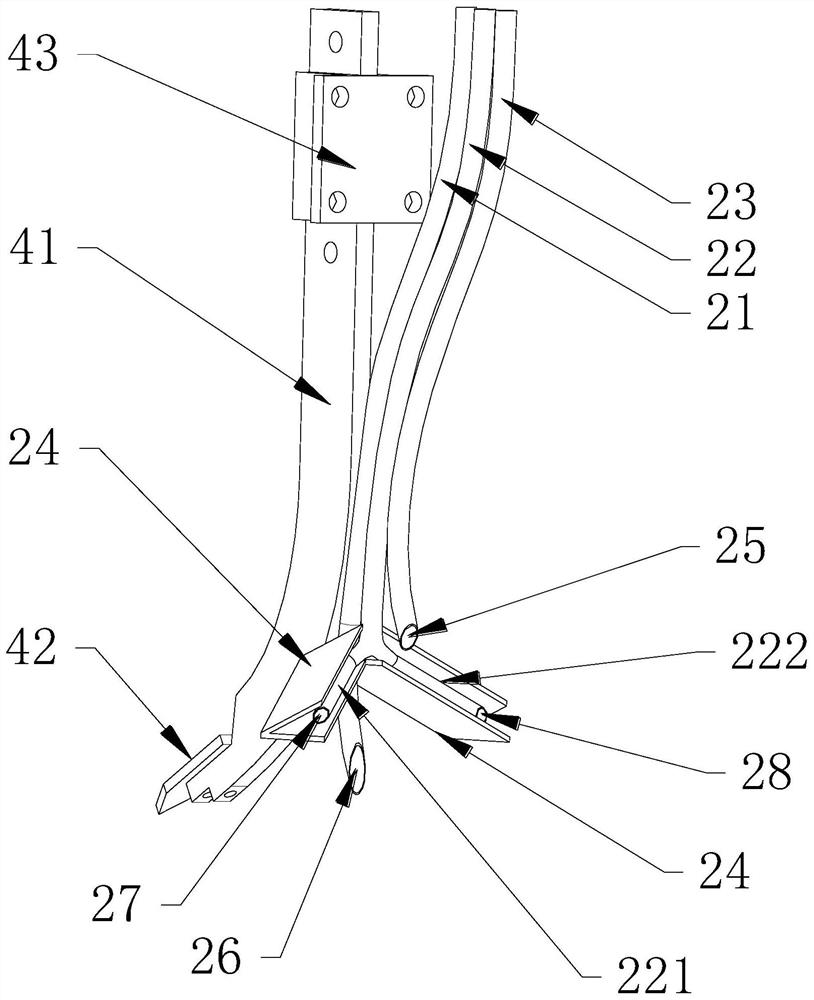

[0032] The fertilization pipe group 2 is composed of the lower fertilization pipe 21, the middle fertilization pipe 22 and the upper fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com