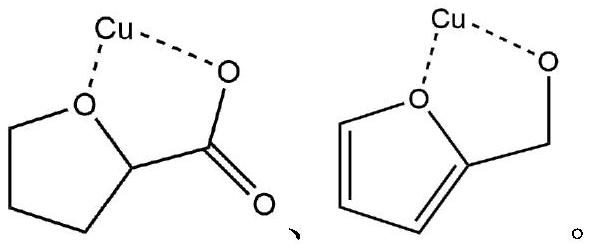

Oxygen-containing polydentate ligand modified copper-based catalyst for acetylene hydrochlorination reaction as well as preparation method and application thereof

A technology of acetylene hydrochlorination and copper-based catalysts, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of poor stability and low activity, To achieve the effect of enhancing the activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

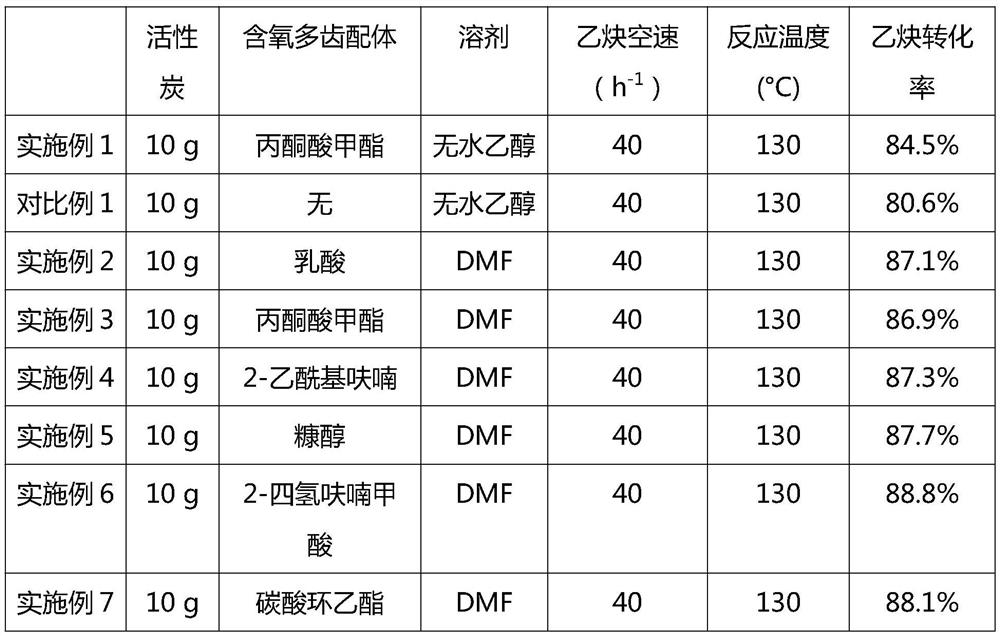

Embodiment 1

[0041] (1) At 50° C., 1.7 g of anhydrous copper chloride and 0.61 g of methyl pyruvate were stirred and dissolved in 5.5 g of absolute ethanol to obtain an impregnation solution containing copper ions and ligands;

[0042](2) Immerse the impregnating solution onto 10 g of activated carbon by equal-volume impregnation method, and leave it sealed at 50° C. for 1 hour;

[0043] (3) Dry the activated carbon at 95° C. for 20 hours to obtain catalyst A1.

[0044] A1 The reaction condition is 130°C, the acetylene space velocity is 40h -1 , when the volume ratio of hydrogen chloride to acetylene is 1.2:1, the conversion rate of acetylene is 84.5%.

Embodiment 2

[0051] (1) At 50° C., 1.7 g of anhydrous copper chloride and 0.54 g of lactic acid were stirred and dissolved in 5.5 g of N, N-dimethylformamide to obtain an impregnation solution containing copper ions and ligands;

[0052] (2) Immerse the impregnating solution onto 10 g of activated carbon by equal-volume impregnation method, and leave it sealed at 50° C. for 1 hour;

[0053] (3) Dry the activated carbon at 170° C. for 20 hours to obtain catalyst A3.

[0054] A3 The reaction condition is 130°C, and the space velocity of acetylene is 40h -1 , when the volume ratio of hydrogen chloride to acetylene is 1.2:1, the conversion rate of acetylene is 87.1%.

Embodiment 3

[0056] (1) At 50° C., 1.7 g of anhydrous copper chloride and 0.61 g of methyl pyruvate were stirred and dissolved in 5.5 g of N, N-dimethylformamide to obtain an impregnation solution containing copper ions and ligands;

[0057] (2) Immerse the impregnating solution onto 10 g of activated carbon by equal-volume impregnation method, and leave it sealed at 50° C. for 1 hour;

[0058] (3) Dry the activated carbon at 170° C. for 20 hours to obtain catalyst A4.

[0059] A4 The reaction condition is 130°C and the space velocity of acetylene is 40h -1 , when the volume ratio of hydrogen chloride to acetylene is 1.2:1, the conversion rate of acetylene is 86.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com