Ceramic part sand blasting method, ceramic part and manufacturing method of ceramic part

A technology of ceramic parts and sandblasting, which is applied in the field of ceramic parts and its production, and the field of ceramic parts sandblasting, which can solve the problems of loose particles falling, unable to meet the requirements of surface roughness, and unable to control surface roughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

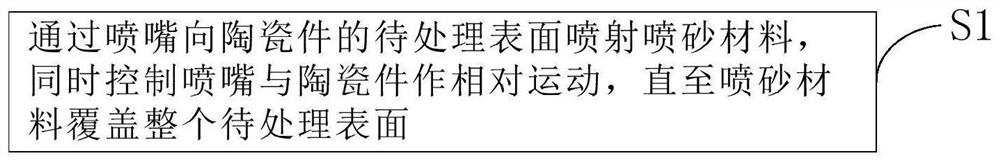

[0035] see image 3 , the present embodiment provides a sandblasting method for ceramic parts, which includes performing the following steps cyclically:

[0036] S1. Spray sandblasting material on the surface of the ceramic part to be treated through the nozzle, and at the same time control the relative movement of the nozzle and the ceramic part until the sandblasting material covers the entire surface to be treated.

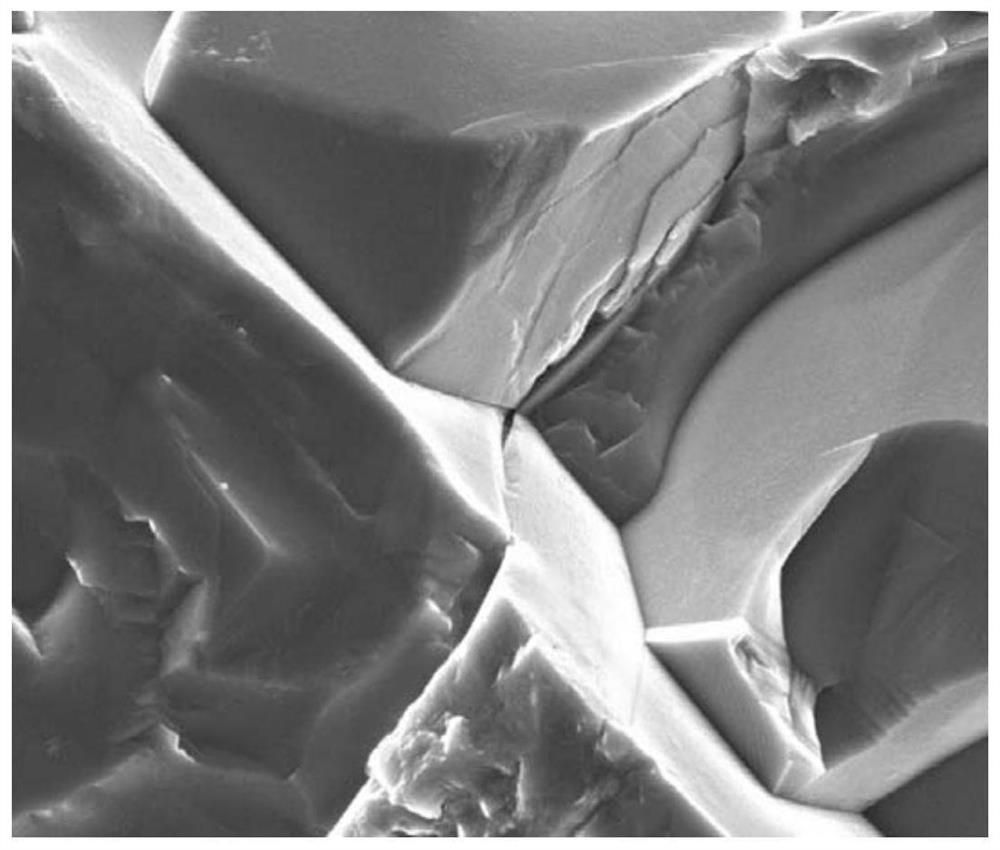

[0037] The above step S1 is used to obtain a certain surface roughness on the surface of the ceramic part. The so-called sand blasting refers to the use of compressed air as the power to form a high-speed jet beam to spray the sandblasting material onto the surface of the ceramic part to be treated at high speed. Due to the impact and cutting effect of the sandblasting material on the surface of the ceramic part, the surface of the ceramic part is obtained surface roughness.

[0038] Above-mentioned nozzle is for example the nozzle of sandblasting machine, be...

no. 2 example

[0055] Compared with the above-mentioned first embodiment, the sandblasting method for ceramic parts provided by this embodiment also includes step S1 which is executed cyclically, and controls the number of cycles of above-mentioned step S1 and the relevant parameters of each step S1. The parameters are the same as in the first embodiment described above.

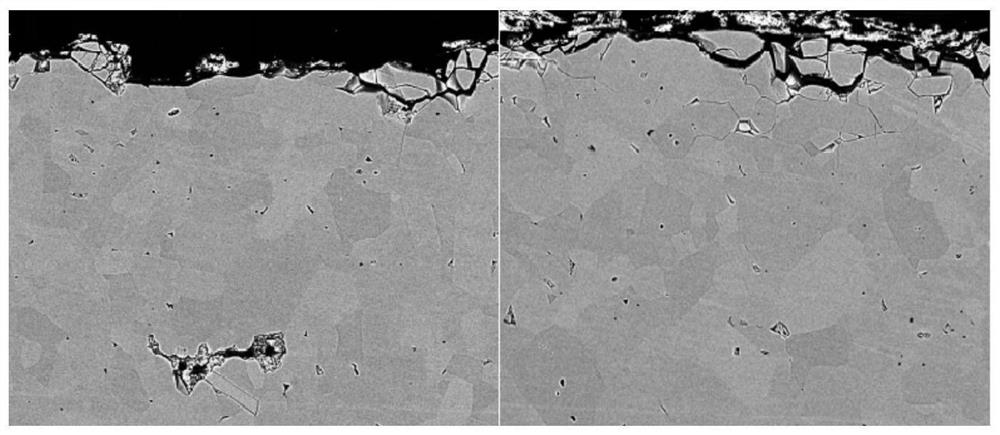

[0056] In this embodiment, different sandblasting meshes are used in different times of step S1. That is to say, corresponding to each number of cycles, the number of sandblasting meshes used in each step S1 is independently set to different numbers, so as to ensure that the ceramic surface will not be damaged when each step S1 is performed.

[0057] Optionally, the number of blasting meshes decreases as the number of cycles increases. This not only helps to improve the uniformity of the surface roughness of the ceramic part, but also does not cause damage to the ceramic surface. Taking the number of sandblasting meshes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com