Light concrete and production process thereof

A technology of lightweight concrete and production process, applied in clay preparation device, mixing operation control, mixing operation control device and other directions, can solve the problems of increasing cost input, affecting production efficiency, etc., to achieve improved quality, good quality of finished products, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

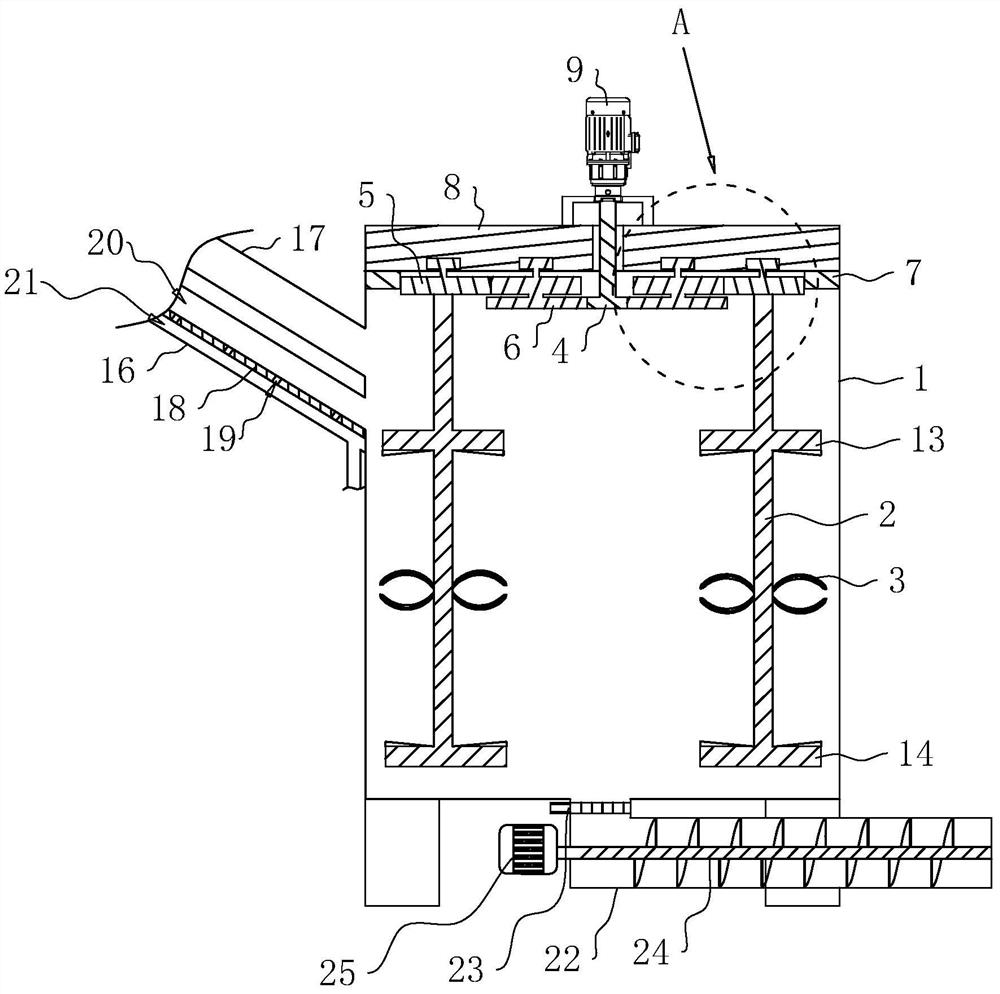

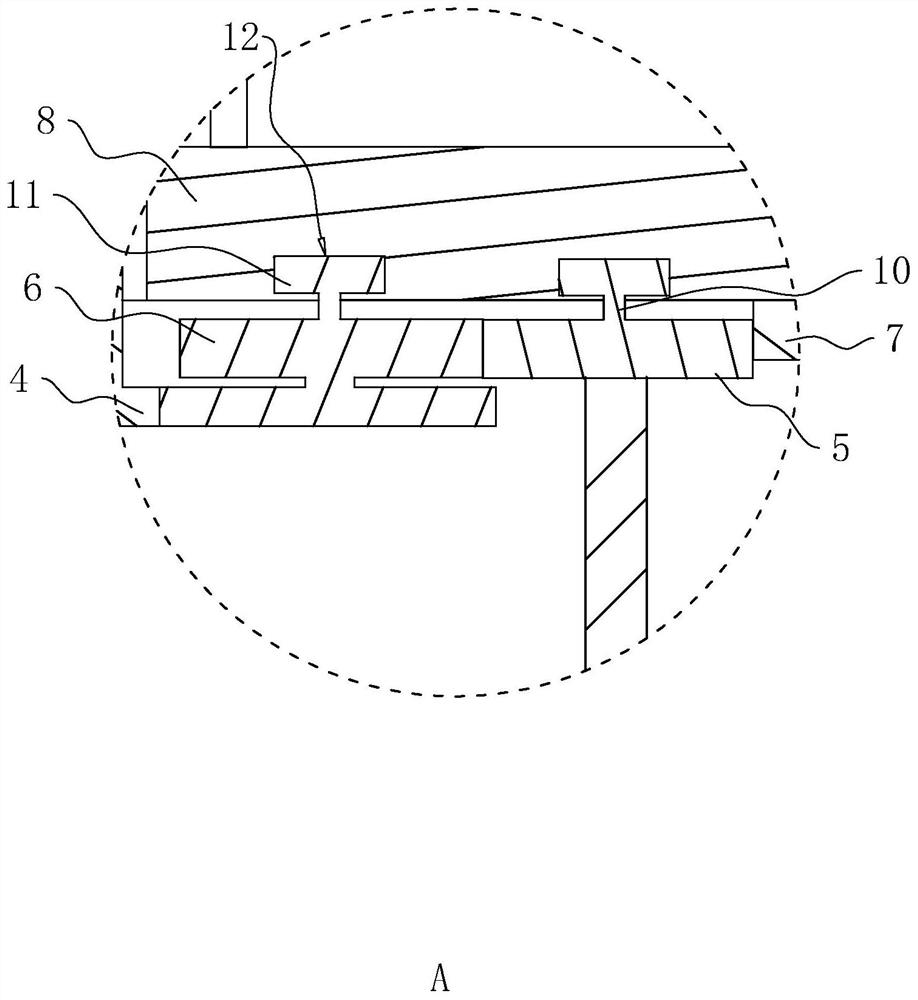

[0036] The following is attached Figure 1-4 The application is described in further detail.

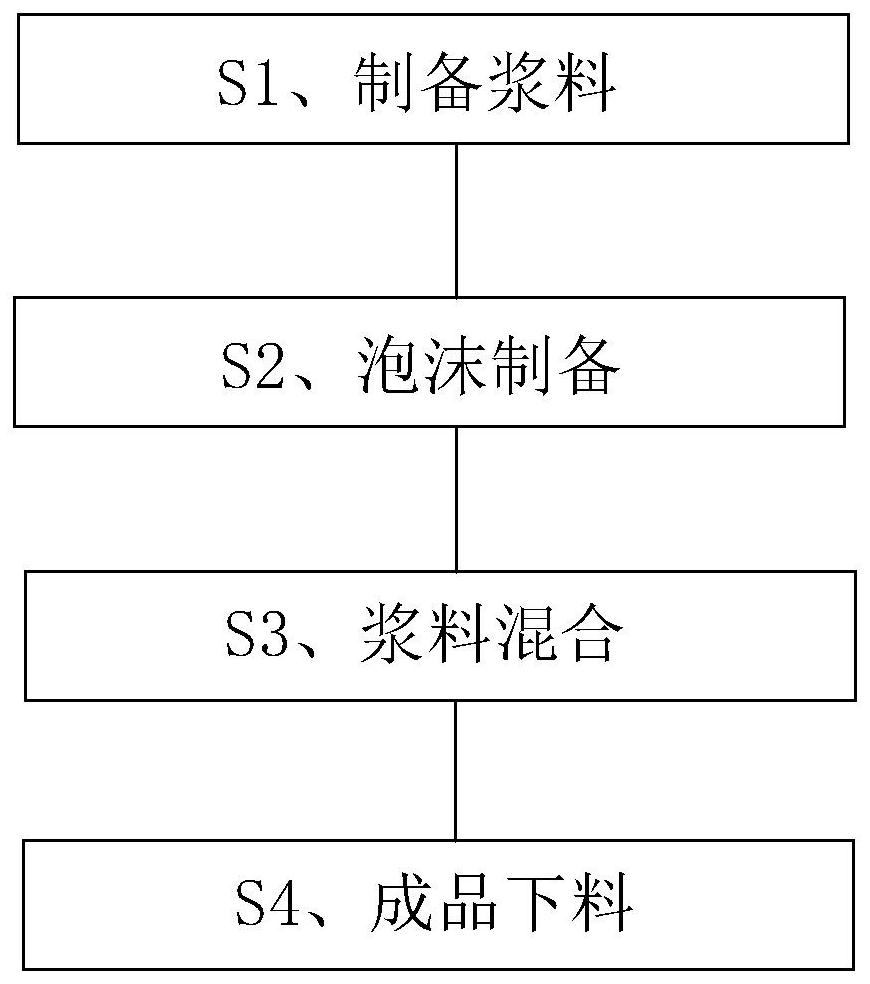

[0037] The embodiment of the present application discloses a process flow chart of a lightweight concrete production process. refer to figure 1 Include the following steps:

[0038] S1. Preparation of slurry: Add a certain proportion into the container and inject water, cement aggregate, active mixed material, polyphenylene particles, regulator and foaming agent in sequence;

[0039] S2. Foam preparation: using a foaming machine to prepare the microfoam into foam;

[0040] S3, slurry mixing: pump the finished products in the two steps of S1 and S2 to the stirring device for stirring and mixing;

[0041] S4. Finished product blanking: transport the mixed slurry from the mixing device to the discharge device, and the discharge device will transport the concrete to the mold for forming and curing.

[0042] Coal fly ash or blast furnace slag can be used as the active mixing material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com