Boron-doped diamond film electrode composite substrate and preparation method thereof

A boron-doped diamond and thin-film electrode technology, which is applied to a boron-doped diamond thin-film electrode composite substrate and its preparation, and the field of boron-doped diamond thin-film electrodes, can solve the problems of short service life, weak resistance to fluid scouring of the substrate, and high degree of corrosion, and achieves the Long service life, strong corrosion resistance and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: During blending diamond thin film electrode composite matrix

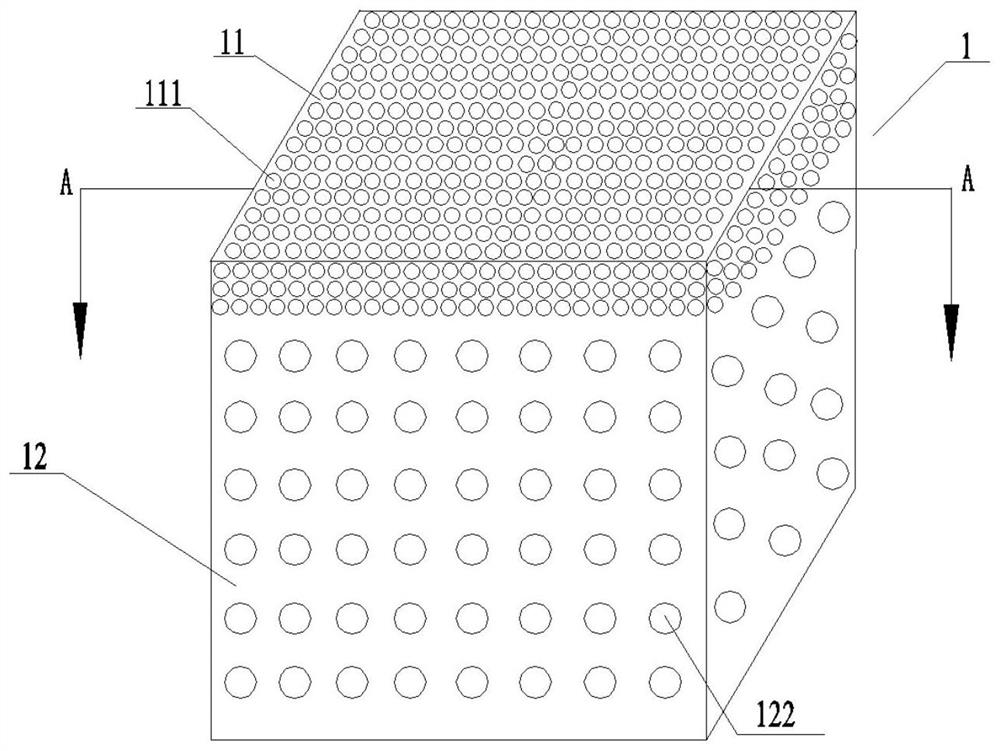

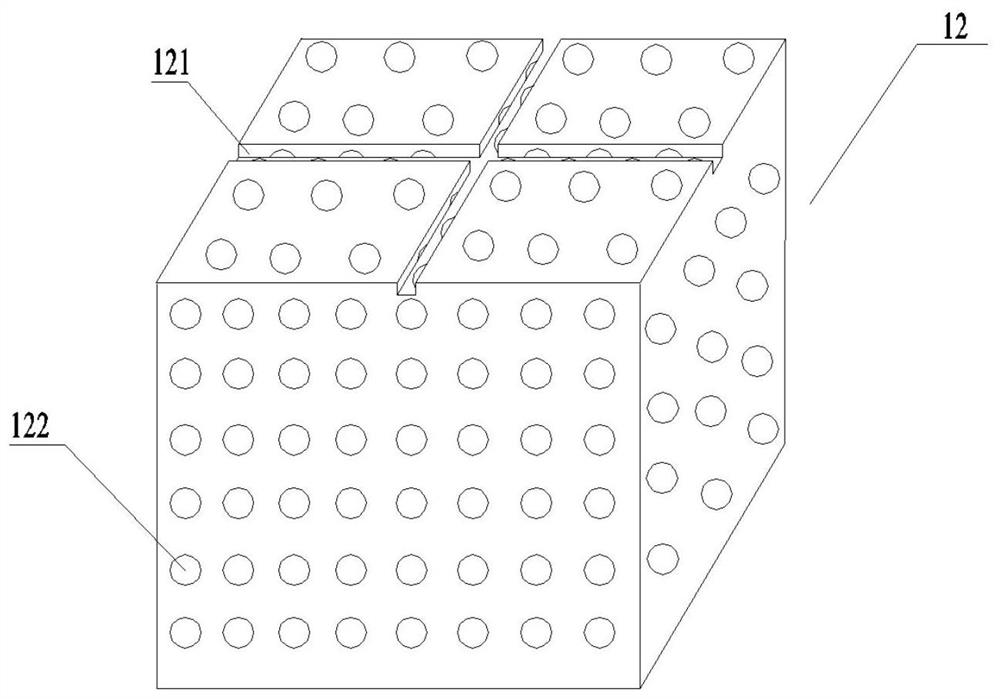

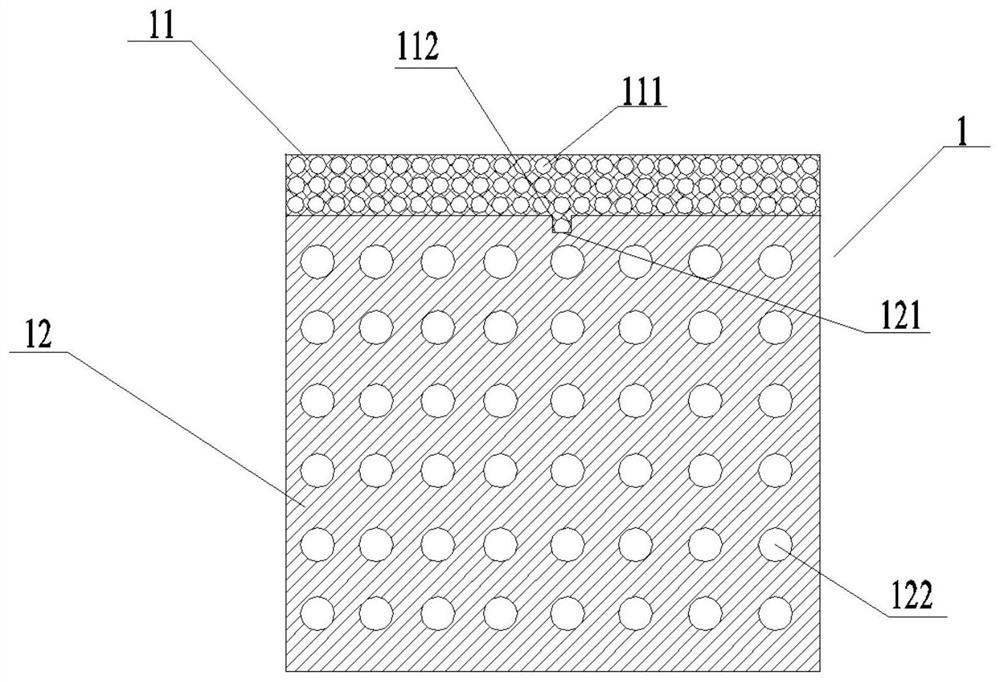

[0030] figure 1 A perspective view of the blended metal diamond thin film electrode composite matrix in this example is shown. figure 2 A perspective view showing the lower portion of the base body of the blended diamond film electrode composite matrix in this embodiment, image 3 The edge of the blended diamond thin film electrode composite matrix in this example is shown in the present embodiment. figure 1 A cross-sectional view of the A-A direction.

[0031] Such as figure 1As shown, the blending diamond thin film electrode composite substrate 1 of the present embodiment includes a base lower portion 12 and an upper portion 11 for depositing a boron diamond film at the upper surface of the base body lower portion 12. The lower portion 12 of the base body is a ceramic material, and the upper portion 11 is a metal material. The lower portion 12 of the base body is strong, the upper portion 11 of the...

Embodiment 2

[0039] Example 2: Preparation method of blended diamond thin film electrode composite matrix

[0040] A method of preparing a blended diamond membrane electrode composite matrix of Example 1, including the following steps:

[0041] S1, preparing ceramic raw materials, using ceramic raw materials to prepare the lower part of the base body, the lower part of the base body is a porous structure consisting of 30% -50% of the porosity of the mutually penetrating regular circular hole;

[0042] S2, the groove is processed on the upper surface of the lower part of the base body to obtain a lower portion of the substrate, the groove is a cross groove of the center of the upper surface of the base body;

[0043] S3, preparing a metal raw material, using a metal feedstock over the upper surface of the base body by 3D printing technique over the upper surface of the projection having the card to be provided in the projection of the projection of the groove, and the upper portion of the subs...

Embodiment 3

[0048] Example 3: A blending diamond film electrode

[0049] A doped diamond film electrode of the present embodiment comprises a blended diamond membrane electrode composite matrix of Example 1. The blending diamond thin film electrode of the present embodiment includes the beneficial effect of the blended diamond thin film electrode composite matrix of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com