Ozone generation control device and system

A technology for ozone generation and control devices, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Small microbubbles and other problems, to achieve the best sewage treatment effect, reduce the generation of bromate, the overall effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

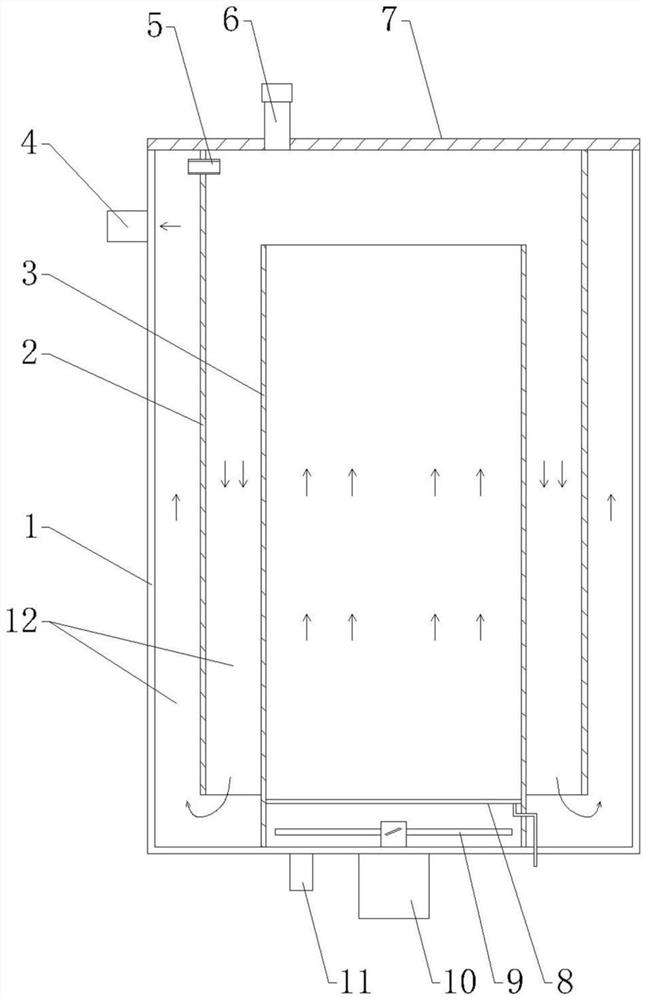

[0030] see figure 1As shown, the present invention provides an ozone generation control device, comprising a main tank 1, the top of the main tank 1 is provided with a detachable cover plate 7, the cover plate 7 is provided with an emptying port 6, the main tank 1 is provided with an inner cylinder 3, the lower end of the inner cylinder 3 is fixed with the bottom surface of the main pipe, the upper end of the inner cylinder 3 is lower than the height of the main tank 1 and the upper end is open, and the bottom of the main tank 1 is provided with a communication with the inner cylinder 3. There is a first spacer 2 between the main tank 1 and the inner cylinder 3, the upper end of the first spacer 2 is fixed with the bottom surface of the cover plate 7, and the lower end of the first spacer 2 is connected to the main tank. There is a gap between the bottom surfaces of the 1, the upper end side of the first spacer 2 is provided with a pressure equalizing port 5, and the height of...

Embodiment 2

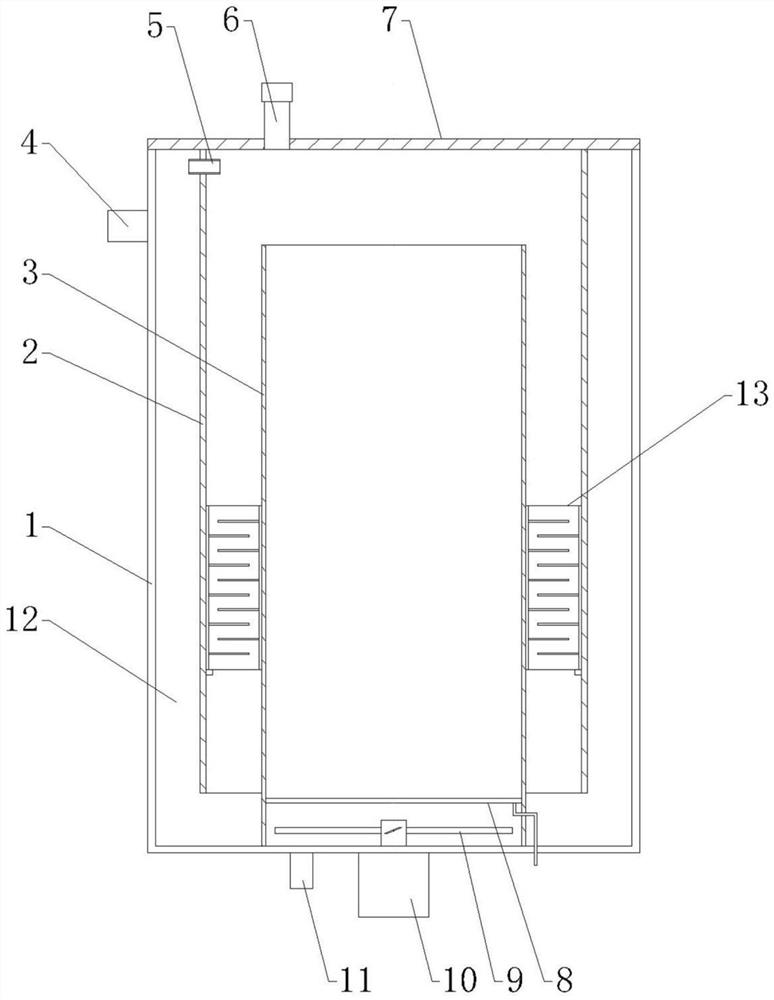

[0033] see figure 2 As shown, this embodiment is further improved on the basis of Embodiment 1. In this embodiment, a detachable first spacer is added in the slow flow channel 12 between the first spacer 2 and the inner cylinder 3 The flow damper 13, by adding the first damper 13, can further lengthen the purification process and purification time of the sewage, and further improve the sewage purification effect, and the first damper 13 is also easy to install and disassemble, which is convenient for later maintenance. .

[0034] Three preferred structures and installation methods of the first damper 13 are provided below:

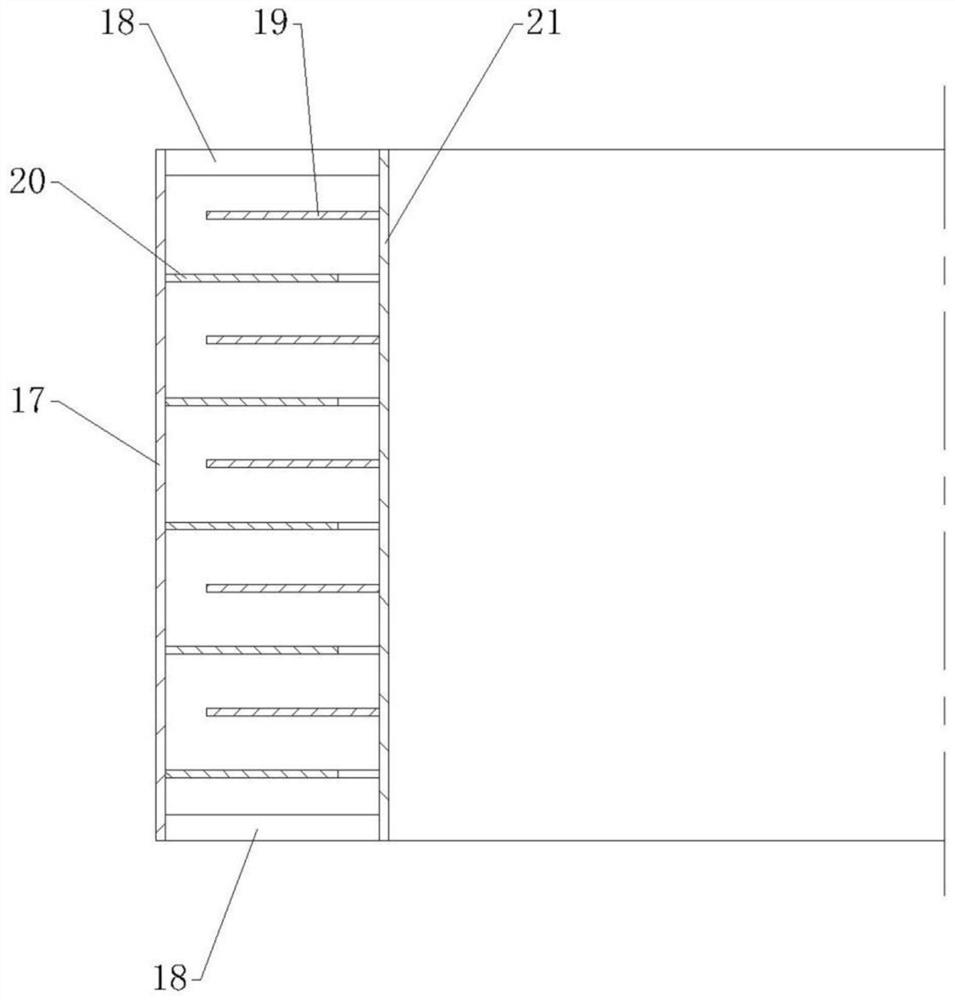

[0035] 1) see image 3 and Figure 4 As shown, the first damper 13 includes a first sleeve 17 and a second sleeve 21 disposed inside the first sleeve 17 , between the upper end of the first sleeve 17 and the upper end of the second sleeve 21 And the lower end of the first sleeve 17 and the lower end of the second sleeve 21 are connected and fixed by e...

Embodiment 3

[0039] see Figure 10 As shown, this embodiment is further improved on the basis of implementation 2. In this embodiment, a second damper 14 is added in the slow flow channel 12 between the first spacer 2 and the main tank 1. The structure of the second damper 14 can be the same as any one of the three first dampers 13 provided in the second embodiment. The flow damper 14 can be matched with the installation space between the first spacer 2 and the main tank 1 .

[0040] see Figure 11 As shown, the present invention also provides an ozone generation control system, including an ozone generator 15, an air pump 16 connected to the ozone generator 15 and the aforementioned ozone generation control device, the aeration coil 8 is connected to the air pump through a pipeline The gas outlet end of 16 is connected, and ozone gas is supplied into the inner cylinder 3 by the ozone generator 15 . The ozone generation control system can effectively reduce the generation of bromate whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com