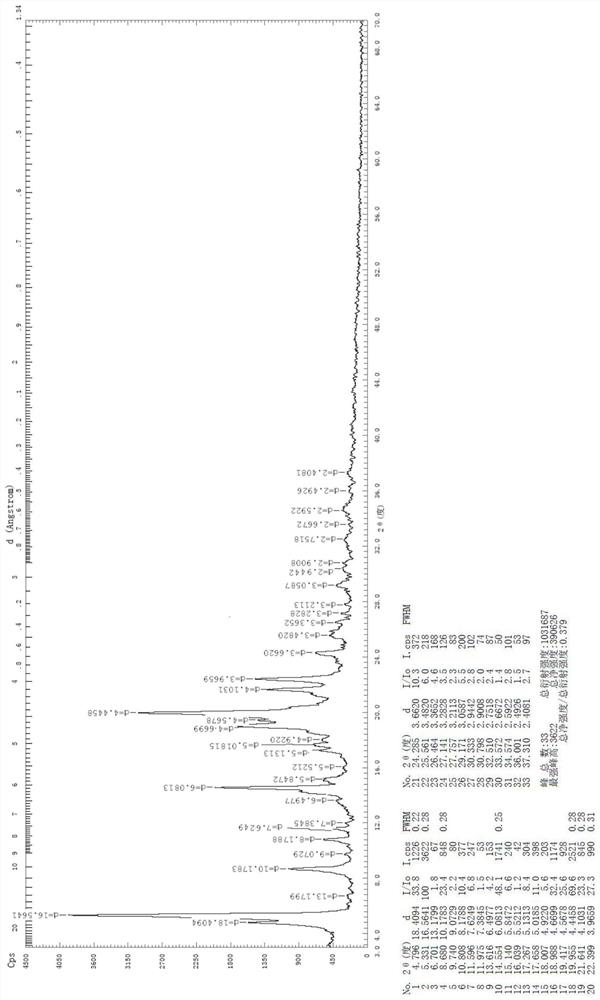

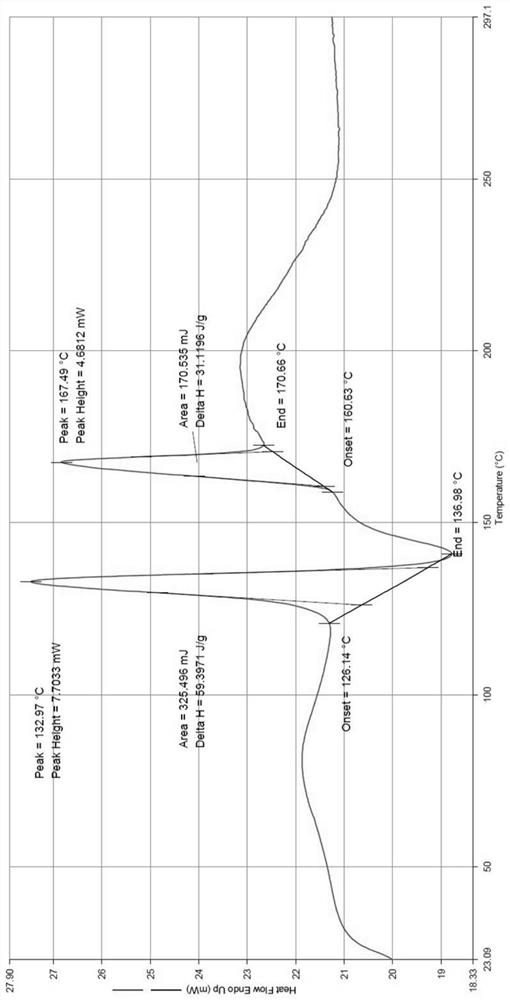

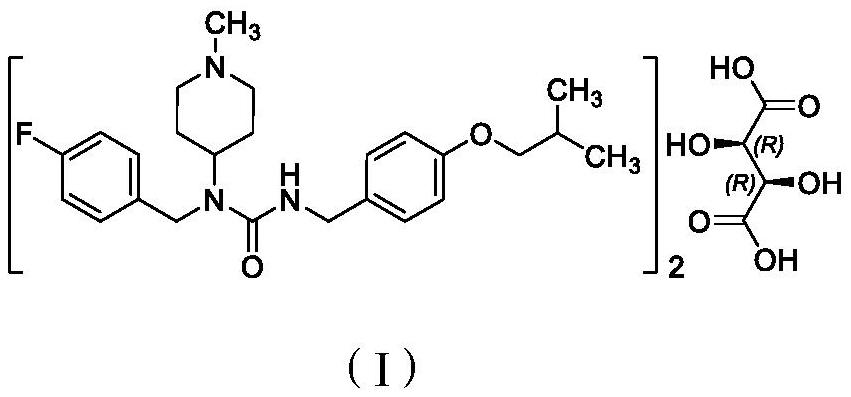

Preparation method of tartaric acid pimavanserin crystal form A

A technology of pimavanserin and tartaric acid, which is applied in the field of preparation of pimavanserin tartrate crystal form A, can solve the problem of low yield and crystal form purity of crystal form C, low crystal form purity, and crystal form A between batches big differences etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 198

[0069] Embodiment 1 prepares pimavanserin tartrate crystal form A with 98% ethanol aqueous solution

[0070] Salt formation: Add 9.94kg of pimavanserin and 98% ethanol aqueous solution (49.71kg) into the reaction kettle, stir and heat up to 50°C, and drop L-tartaric acid (1.74kg)-98 % ethanol aqueous solution (8.70kg), after adding, cool down to 40°C and stir for 0.5h. After a large amount of solids are precipitated, cool down to -5°C, and crystallize at -5°C for 2h, centrifuge and dry, and the wet product is directly refined .

[0071] Refining: add the above-mentioned pimavanserin tartrate filter cake and 98% ethanol aqueous solution (49.71kg) to 2 reaction kettles, stir and raise the temperature to 75°C, cool down to 45°C for crystallization for 0.5h after the material liquid dissolves, a large amount of solid After precipitation, cool down to 15°C, control the temperature at 15°C for crystallization for 2 hours, centrifuge, rinse with 98% ethanol aqueous solution, spin dr...

Embodiment 298

[0074] Example 2 Preparation of pimavanserin tartrate crystal form A with 98.5% aqueous ethanol

[0075] Salt formation: Add 9.94kg of pimavanserin and 98.5% ethanol aqueous solution (49.71kg) into the reaction kettle, stir and heat up to 40°C, and drop L-tartaric acid (1.74kg)-98.5 % ethanol aqueous solution (13.92kg), after adding, cool down to 40°C and stir for 0.5h. After a large amount of solids are precipitated, cool down to 0°C, and crystallize at 0°C for 2h, centrifuge to dry, and the wet product is directly refined.

[0076] Refining: add the above-mentioned pimavanserin tartrate filter cake and 98.5% ethanol aqueous solution (49.71kg) to 2 reaction kettles, stir and heat up to 78°C, cool down to 45°C to crystallize for 0.5h after the material solution dissolves, a large amount of solid After precipitation, cool down to 20°C, control the temperature at 20°C for crystallization for 2 hours, centrifuge, rinse with 98.5% ethanol aqueous solution, spin dry, and dry in vac...

Embodiment 395

[0079] Embodiment 3 prepares pimavanserin tartrate crystal form A with 95% ethanol aqueous solution

[0080] Salt formation: Add 9.94kg of pimavanserin and 95% ethanol aqueous solution (49.71kg) into the reaction kettle, stir and heat up to 50°C, and drop L-tartaric acid (1.74kg)-95 % ethanol aqueous solution (5.22kg), after adding, cool down to 45°C and stir for 0.5h. After a large amount of solids are precipitated, cool down to 5°C, and crystallize at 5°C for 2h, centrifuge to dry, and the wet product is directly refined.

[0081] Refining: add the above-mentioned pimavanserin tartrate filter cake and 95% ethanol aqueous solution (49.71kg) to 2 reaction kettles, stir and heat up to 75°C, cool down to 45°C for 0.5h to crystallize after the material liquid dissolves, a large amount of solid After the precipitation, cool down to 15°C, control the temperature at 15°C for crystallization for 2 hours, centrifuge, rinse with 95% ethanol aqueous solution, spin dry, and dry in a vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com