Preparation method of black matte polyimide film

A technology of polyimide film and black matte, which is applied in the field of film materials, can solve the problems such as the reduction of mechanical properties of polyimide film, and achieve the effect of good mechanical properties and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

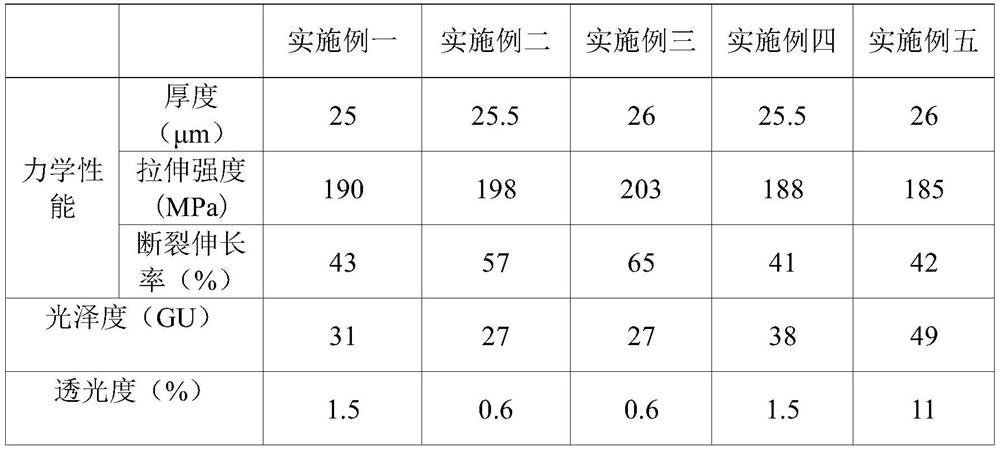

Examples

Embodiment 1

[0025] The preparation method of black matte polyimide film is as follows:

[0026] (1) Preparation of emulsion

[0027] Carbon black and silicon dioxide (5 μm) are added in the ultrasonic dispersion kettle, carbon black accounts for 4% of polyimide matrix quality, and silicon dioxide (5 μm) accounts for 6% of polyimide matrix quality, adds N- Stir the methylpyrrolidone (NMP) solvent, the stirring speed is 1000r / min, and carry out ultrasonic dispersion treatment, the ultrasonic frequency is 20kHz, the power is 2000W, and the processing time is 60min to obtain a black emulsion;

[0028] (2) Preparation of amine solution

[0029] Add 4,4'-diaminodiphenyl ether into the reaction kettle, add dimethylformamide solvent to dissolve, and stir at 80r / min until the crystals of 4,4'-diaminodiphenyl ether are completely dissolved in the solvent , to obtain amine solution;

[0030] (3) emulsification

[0031] Add the dispersed black emulsion into the dissolved amine liquid, and add pol...

Embodiment 2

[0037] The preparation method of black matte polyimide film is as follows:

[0038] (1) Preparation of emulsion

[0039] Carbon black and silicon dioxide (5 μm) are added in the ultrasonic dispersion kettle, carbon black accounts for 6% of polyimide matrix quality, and silicon dioxide (5 μm) accounts for 6% of polyimide matrix quality, adds N- Stir the methylpyrrolidone (NMP) solvent, the stirring speed is 1000r / min, and carry out ultrasonic dispersion treatment, the ultrasonic frequency is 20kHz, the power is 2000W, and the processing time is 60min to obtain a black emulsion;

[0040] (2) Preparation of amine solution

[0041] Add 4,4'-diaminodiphenyl ether into the reaction kettle, add dimethylacetamide solvent to dissolve, and stir at 80r / min until the crystals of 4,4'-diaminodiphenyl ether are completely dissolved in the solvent , to obtain amine solution;

[0042] (3) emulsification

[0043] Add the dispersed black emulsion into the dissolved amine liquid, and add pol...

Embodiment 3

[0049] The preparation method of black matte polyimide film is as follows:

[0050] (1) Preparation of emulsion

[0051] Carbon black and silicon dioxide (5 μm) are added in the ultrasonic dispersion kettle, carbon black accounts for 6% of polyimide matrix quality, and silicon dioxide (5 μm) accounts for 6% of polyimide matrix quality, adds N- Stir the methylpyrrolidone (NMP) solvent, the stirring speed is 1000r / min, and carry out ultrasonic dispersion treatment, the ultrasonic frequency is 20kHz, the power is 2000W, and the processing time is 60min to obtain a black emulsion;

[0052] (2) Preparation of amine solution

[0053] Add 4,4'-diaminodiphenyl ether into the reaction kettle, add dimethylacetamide solvent to dissolve, and stir at 80r / min until the crystals of 4,4'-diaminodiphenyl ether are completely dissolved in the solvent , to obtain amine solution;

[0054] (3) emulsification

[0055] Add the dispersed black emulsion into the dissolved amine liquid, and add pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com