Antibacterial water-resistant material and preparation method thereof

A technology of waterproof material and matrix material, applied in the field of preparation of antibacterial and water-resistant materials, can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention also discloses a preparation method of an antibacterial and water-resistant material, comprising the following steps:

[0032] A1. Dissolving amylose in a solvent at 20-60°C to prepare an amylose solution, and dissolving tea polyphenols in a solvent at 20-50°C to prepare a tea polyphenol solution. During the preparation of the two solutions, Continuously stir the solution by means of mechanical stirring, the stirring rate is 20-60r / min, stop stirring until it is completely dissolved. Mix the two solutions evenly at 20-60°C and keep stirring the mixed solution, add the cross-linking agent into the mixed solution at 20-60°C, and continuously stir the mixed solution by mechanical stirring at a stirring rate of 50-150r / min , the stirring time is continued for 30-120 minutes, so that the hydroxyl groups of amylose and the phenolic hydroxyl groups of tea polyphenols are cross-linked to form a cross-linked product with a network structure, and a matrix material i...

Embodiment

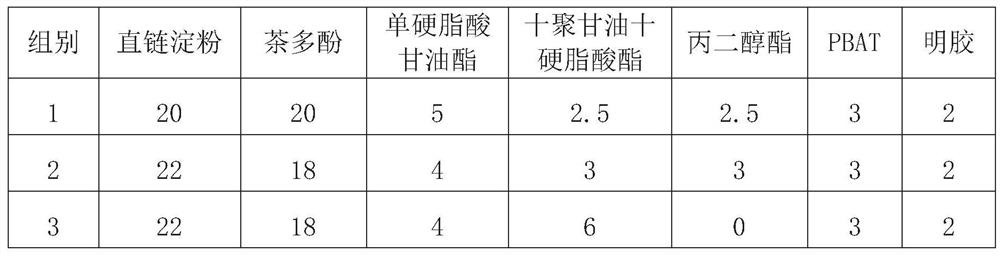

[0038] 1. Prepare antibacterial waterproof materials according to the above-mentioned formula and method. The specific proportions are shown in Table 1 below. All groups in Table 1 are carried out according to the following operating parameters: after adding the cross-linking agent, the cross-linking reaction temperature is 50°C, the stirring rate is 120r / min, and the stirring time is 40min; after adding the fatty acid ester for compounding, the compounding reaction temperature is 50°C, the stirring rate is 80r / min, and the stirring time is 50min; after adding the fatty acid ester for hydrophobicity, The ultrasonic oscillation time is 20min, and the processing power is 500W; after adding the composite material of PBAT and gelatin, the film material is extruded with a screw extruder at 100°C.

[0039] Each group proportioning (parts by weight) of table 1

[0040]

[0041] 2. After the bacteriostatic waterproof materials made by the above groups are made into thin films, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com