High-elasticity antibacterial fabric as well as preparation method and application thereof

An antibacterial fabric, high elasticity technology, applied in textile and papermaking, textile, biochemical fiber treatment and other directions, can solve the problem that the fabric cannot take into account the antibacterial function and comfort, and achieve the effect of improving the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

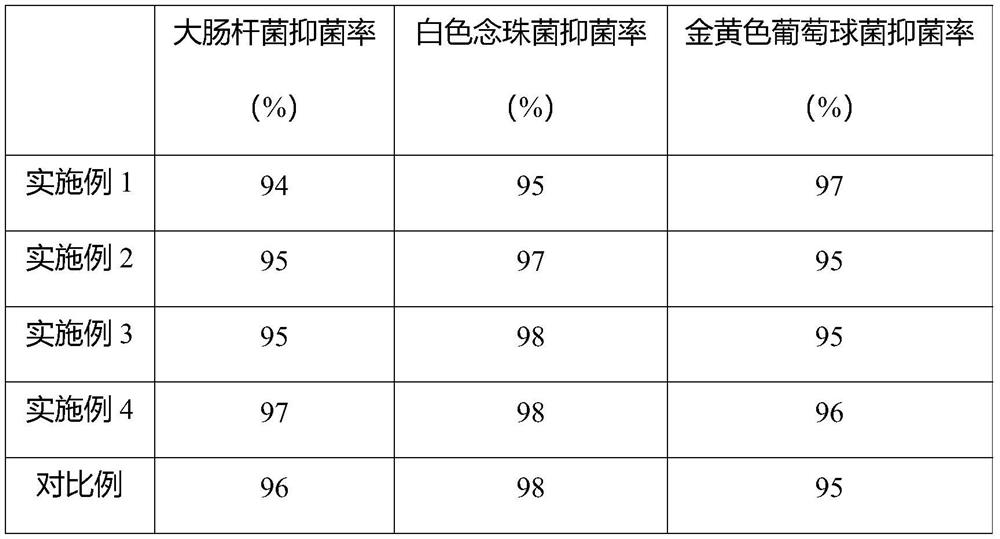

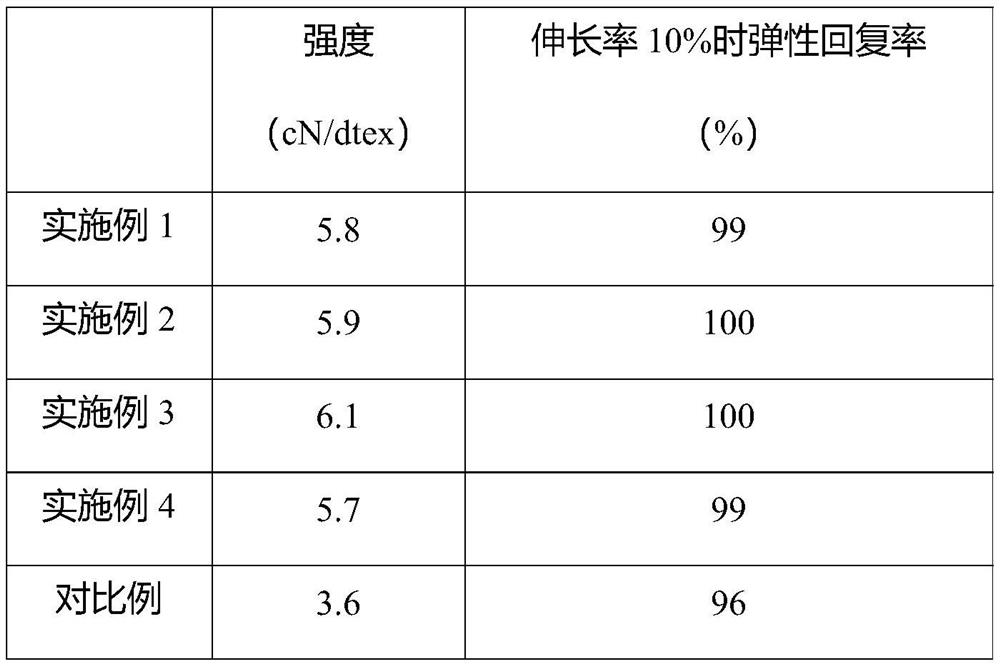

Examples

Embodiment 1

[0027] A preparation method of highly elastic antibacterial fabric, comprising the following steps:

[0028] A. Mix 20 parts of modal fiber, 30 parts of seaweed charcoal fiber, 15 parts of viscose fiber, 10 parts of bamboo charcoal fiber and 10 parts of jade fiber in parts by mass, stir evenly, then add 2 parts of dispersant and 3 parts of antioxidant, Add 120 parts of solvent and stir at 60°C for 1 h;

[0029] B. After drying at 60°C, soak in antibacterial solution for 6 hours for antibacterial treatment;

[0030] C. Dry at 60°C, and obtain yarn through the processes of cleaning, carding, drawing, roving and spun yarn;

[0031] D, the yarn that step C obtains obtains highly elastic antibacterial fabric through knitting or weaving;

[0032] The mass fraction of sodium alginate contained in the seaweed charcoal fiber is 6%, the jade fiber is obtained by mixing jade with a particle size of 500-800nm into polyester fiber, and the fineness is 2.4D. The antibacterial liquid is ...

Embodiment 2

[0043] A preparation method of highly elastic antibacterial fabric, comprising the following steps:

[0044] A. Mix 50 parts of modal fiber, 40 parts of seaweed charcoal fiber, 25 parts of viscose fiber, 20 parts of bamboo charcoal fiber and 20 parts of jade fiber in parts by mass, stir evenly, then add 8 parts of dispersant and 5 parts of antioxidant, Add 150 parts of solvent and stir at 80°C for 3h;

[0045] B. After drying at 80°C, soak in antibacterial solution for 24 hours for antibacterial treatment;

[0046] C. Dry at 80°C, and obtain yarn through the processes of cleaning, carding, drawing, roving and spun yarn;

[0047] D, the yarn that step C obtains obtains highly elastic antibacterial fabric through knitting or weaving;

[0048] The mass fraction of sodium alginate contained in the seaweed charcoal fiber is 8%, the jade fiber is obtained by mixing jade with a particle size of 500-800nm into polyester fiber, and the fineness is 2.4D. The antibacterial liquid is ...

Embodiment 3

[0059] A preparation method of highly elastic antibacterial fabric, comprising the following steps:

[0060] A. Mix 30 parts of modal fiber, 35 parts of seaweed charcoal fiber, 20 parts of viscose fiber, 15 parts of bamboo charcoal fiber and 15 parts of jade fiber in parts by mass, stir evenly, then add 5 parts of dispersant and 4 parts of antioxidant, Add 140 parts of solvent and stir at 70°C for 2h;

[0061] B. After drying at 70°C, soak in antibacterial solution for 12 hours for antibacterial treatment;

[0062] C. Dry at 70°C, and obtain yarn through the processes of cleaning, carding, drawing, roving and spun yarn;

[0063] D, the yarn that step C obtains obtains highly elastic antibacterial fabric through knitting or weaving;

[0064] The mass fraction of sodium alginate contained in the seaweed charcoal fiber is 7%, the jade fiber is obtained by mixing jade with a particle size of 500-800nm into polyester fiber, and the fineness is 2.4D. The antibacterial liquid is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com