Method for detecting melamine in milk

A technology of melamine and detection method, which is applied in the direction of material analysis by observing the influence on chemical indicators, and analysis by chemical reaction of materials, etc., can solve the complicated operation steps, high cost of equipment and instruments, and difficult commercial application question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present embodiment provides a kind of detection method of melamine in milk, comprising the following steps:

[0027] S1: Mix 2 mL of trichloroacetic acid with a mass fraction of 10% and 5 mL of milk to be tested to obtain a mixed solution A. Mix the mixed solution A ultrasonically at a frequency of 78 Hz for 20 minutes and then stir for 10 minutes;

[0028] S2: Centrifuge the mixed solution A of S1 at a speed of 10,000 rpm for 15 minutes to obtain a supernatant, and then use 1mol / L NaOH solution to adjust the pH value of the supernatant to 7. After the adjustment, the volume of the supernatant is 3 mL;

[0029] S3: Add 30 μL of gallic acid and 30 μL of 1mol / L sodium hydroxide solution to 3 mL of the supernatant in sequence and stir evenly to prepare mixed solution B;

[0030] S4: Add 60 μL of 10 μmol / L silver nitrate solution to the mixed solution B of S3 to obtain the mixed solution C, then transfer it to a cuvette with a thickness of 2 cm, and let it stand for 15 ...

Embodiment 2

[0036] The raw material used in this embodiment and mode of operation are all identical with embodiment 1, difference is:

[0037] In S1, the ultrasonic frequency is 130KHZ, the ultrasonic mixing time is 18min, and the stirring time is 8min;

[0038] In S2, the centrifugation speed is 12000rpm, the centrifugation time is 13min, and the pH value of the supernatant is adjusted to 8;

[0039] In S4, the standing time is 13min;

[0040] In b, the standing time is 13 minutes.

Embodiment 3

[0042] The raw material used in this embodiment and mode of operation are all identical with embodiment 1, difference is:

[0043] In S1, the ultrasonic frequency is 25KHZ, the ultrasonic mixing time is 22min, and the stirring time is 12min;

[0044] In S2, the centrifugation speed is 8000rpm, the centrifugation time is 17min, and the pH value of the supernatant is adjusted to 9;

[0045] In S4, the standing time is 17min;

[0046] In b, the standing time is 17 minutes.

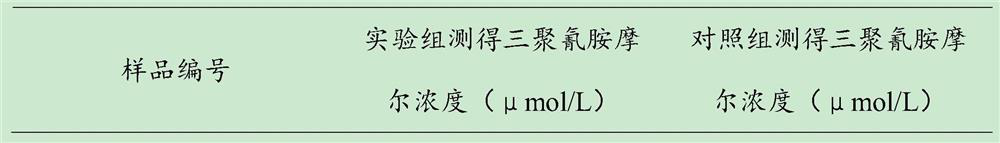

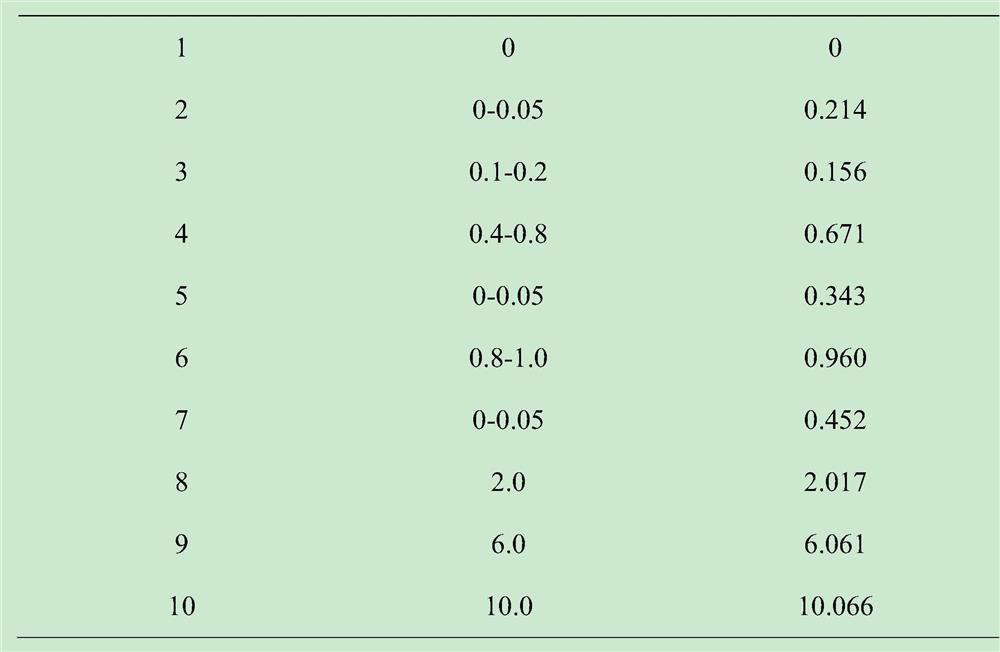

[0047] Now choose embodiment 1 as preferred embodiment, it is tested to illustrate effect of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com