Method for opening terminal area of high-efficiency silicon-based micro display device

A technology of a microdisplay device and an opening method, which is applied in the manufacturing of semiconductor devices, electric solid-state devices, and semiconductor/solid-state devices, etc., can solve the problems of long process time, poor glue exposure and development, and poor bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

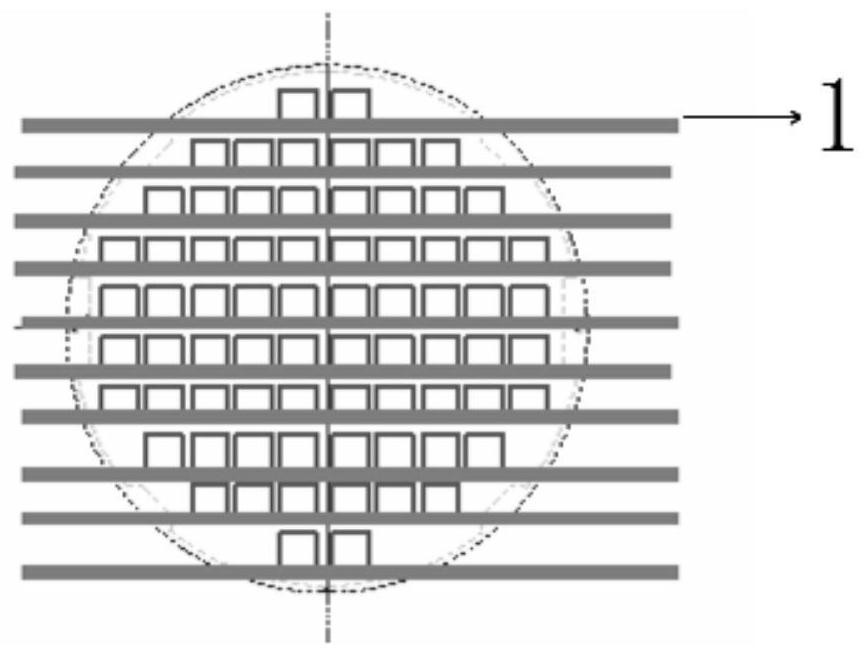

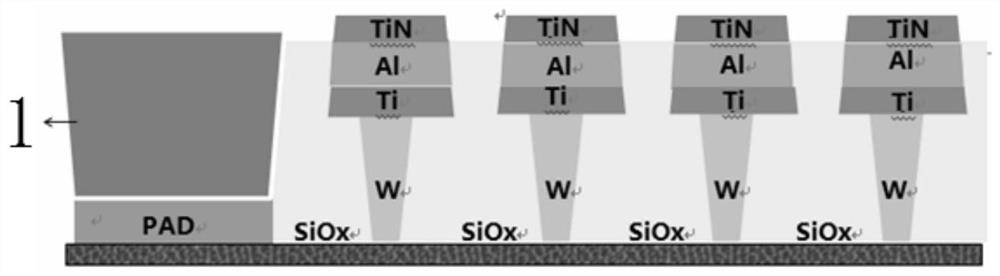

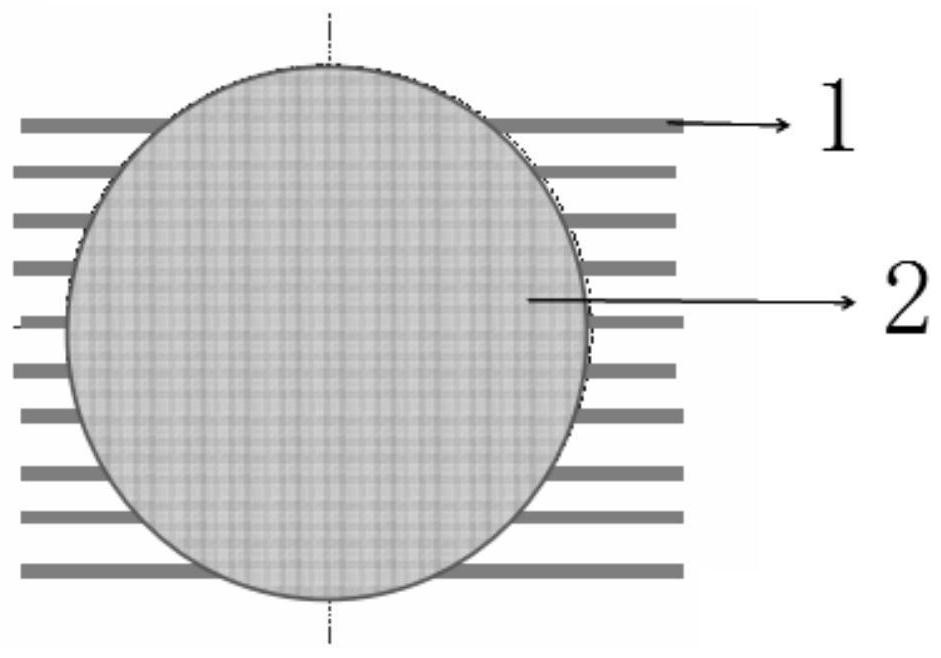

[0031] Such as Figure 1 to Figure 6 As shown, the method for opening the terminal region of the high-efficiency silicon-based micro-display device comprises the following steps:

[0032] Step 1, PET tape bonding:

[0033] After completing the front-end process, stick PET tape on the PAD area;

[0034] Step 2. Encapsulation operation:

[0035] Perform OLED and film encapsulation operations on the sheet pasted with PET tape to form the PET encapsulation layer 2;

[0036] Step 3, PET tape removal:

[0037] Remove the PET tape on the OLED and film-encapsulated film, so that the PAD area is exposed;

[0038] Step four, cleaning:

[0039] Cleaning the silicon wafer in Step 3 to complete the process of opening the terminal area.

[0040] in,

[0041] The PET tape is a high-temperature-resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com