Preparation method of low-temperature-resistant fresh wet noodles

A low-temperature, fresh-moisture-resistant technology, which is applied in the field of food engineering, can solve the problems of not allowing preservatives to be added to fresh-wet powder, restricting the development of the fresh-wet powder industry, and increasing the number of broken strands of fresh-wet powder, so as to improve storage characteristics and be less prone to breakage. strips, the effect of inhibiting aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

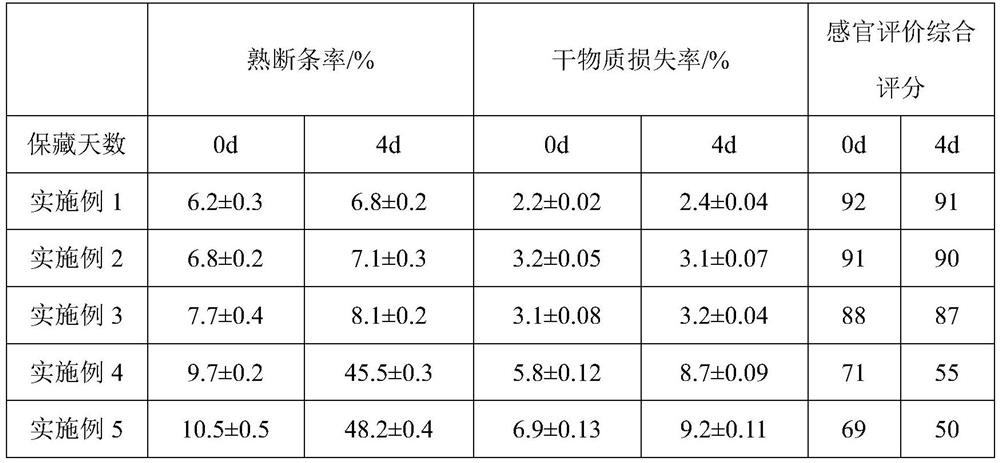

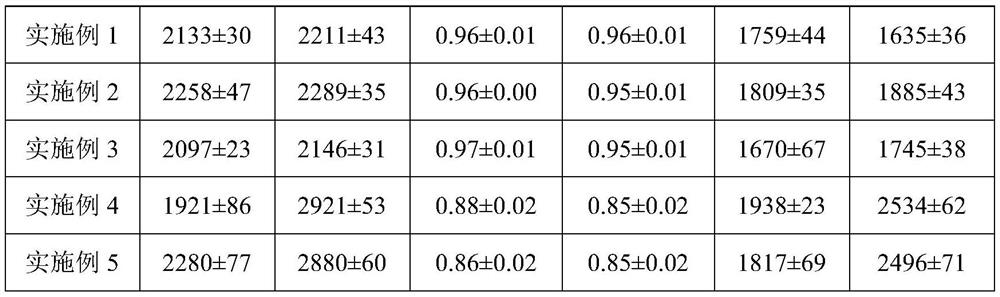

Examples

Embodiment 1

[0044] Mix 90 parts of early indica rice and 10 parts of late indica rice, soak rice, refine pulp, plate and frame press filter, dry, and pass through a 100-mesh sieve to obtain the required rice flour.

[0045] Mix 8 parts of tapioca starch, 10 parts of acetate starch, 0.5 part of salt, 0.3 part of phosphate, 0.5 part of monoglyceride and 80 parts of rice flour to prepare special flour.

[0046] The special powder is mixed with water, and the moisture content is adjusted to 62%. After stirring evenly, it is extruded into an extruder for molding and pre-cooking. The temperature of the sleeve is adjusted to 85°C. After the extruded rice vermicelli is sprayed with α-amylase, Enter the steam box for re-steaming, adjust the steam temperature to 100°C, the pressure to 0.3MPa, and the re-steaming time to 170s. After air-cooling, cut off the packaging to obtain low-temperature-resistant fresh wet powder.

Embodiment 2

[0048] Mix 85 parts of early indica rice and 15 parts of late indica rice, soak the rice, refine the pulp, press filter with plate and frame, dry, and pass through a 100-mesh sieve to obtain the required rice flour.

[0049] Mix 5 parts of tapioca starch, 12 parts of acetate starch, 0.2 part of salt, 0.6 part of phosphate, 0.2 part of monoglyceride and 70 parts of rice flour to prepare special powder.

[0050] The special powder is mixed with water, and the moisture content is adjusted to 64%. After stirring evenly, it is extruded into the extruder for molding and pre-cooking. The temperature of the sleeve is adjusted to 95°C. After the extruded rice vermicelli is sprayed with α-amylase, Enter the steam box for re-steaming, adjust the steam temperature to 102°C, the pressure to 0.25MPa, and the re-steaming time to 180s. After air-cooling, cut off the packaging to obtain low-temperature-resistant fresh wet powder.

Embodiment 3

[0052] Mix 80 parts of early indica rice and 18 parts of late indica rice, soak rice, refine pulp, plate and frame press filter, dry, and pass through a 100-mesh sieve to obtain the required rice flour.

[0053] Mix 11 parts of tapioca starch, 14 parts of acetate starch, 1.2 parts of salt, 0.2 part of phosphate, 0.8 part of monoglyceride and 90 parts of rice flour to prepare special powder.

[0054] The special powder is mixed with water to adjust the moisture content to 61%. After mixing evenly, it is extruded into the extruder for molding and pre-cured. The temperature of the sleeve is adjusted to 80°C. The temperature is 105°C, the pressure is 0.34MPa, the re-steaming time is 150s, and the packaging is cut off after air-cooling to obtain low-temperature resistant fresh wet powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com