Preparation method of pea yoghourt with low beany flavor

A beany smell and pea technology, applied to bacteria, dairy products, milk substitutes, etc. used in food preparation, can solve the problems of animal allergens, complicated process, severe beany smell, etc., and achieve good sensory evaluation, Simple operation, good taste and texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

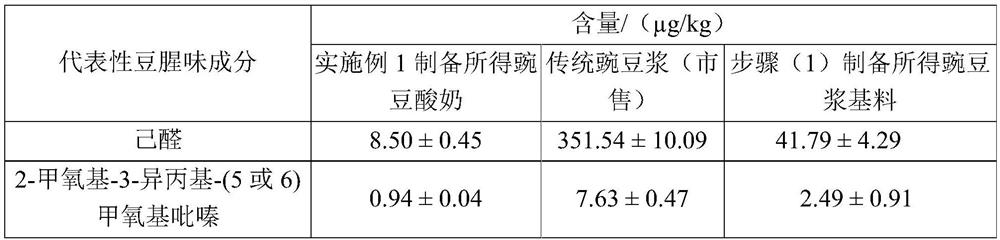

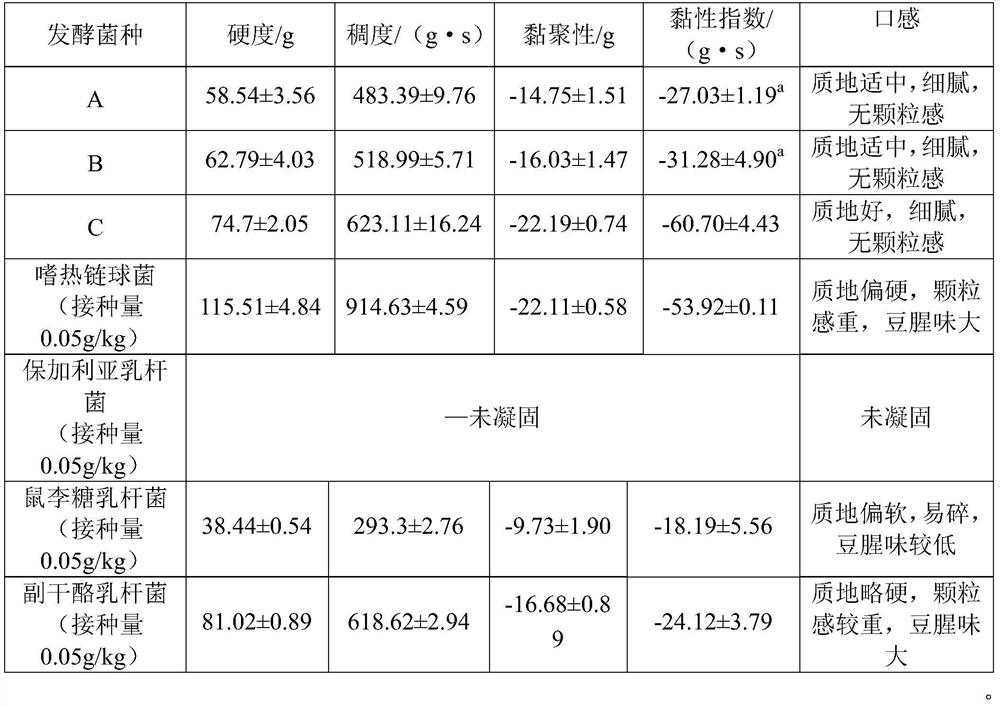

[0033] (1) Preparation of pea milk base material: Weigh 500g of dry peas, put the peas in boiling water for 10 minutes after the water becomes boiling; soak for 15 minutes to achieve the effect of inactivating enzymes; wet shelling after soaking; Take 0.07mol / L phosphoric acid solution, soak for 6 hours according to the mass ratio of beans:water of 1:5, wash with water for 3 hours under stirring, change the water every 1 hour, and take out the beans; Beat the water ratio for 1 minute, adjust the pH to 9.0 with NaOH, maintain it for 30 minutes, centrifuge at 4000g for 15 minutes, take the supernatant, and obtain the pea milk base material with a reduced beany smell; use GC-MS to measure the volatile flavor substances, and the specific data can be found in Table 1; Carry out sensory evaluation to it, specific data see Table 2 for details;

[0034] (2) Ingredients: adjust the above-mentioned pea milk base material with water to a protein concentration of 2.5%; ingredients and ful...

Embodiment 2

[0046] (1) Preparation of pea milk base material: Weigh 1.0kg of dry peas, put the peas in boiling water for 15 minutes, soak them for 20 minutes to achieve the effect of inactivating enzymes; adopt wet method for shelling after soaking; Take 0.07mol / L phosphoric acid solution, soak for 5 hours according to the mass ratio of beans: water of 1:5, wash with water for 4 hours under stirring, change the water every 1 hour, and take out the beans; according to 1:6 (w / w) soybean water Beat the pulp for 1 minute, adjust the pH to 8.0 with NaOH, maintain it for 30 minutes, centrifuge at 4000g for 20 minutes, take the supernatant, and obtain the pea milk base material with a reduced beany smell;

[0047] (2) Ingredients: adjust the protein concentration of the above-mentioned pea milk base material to 3.5% with water, and mix the ingredients and fully stir for 10 minutes; based on the final solution obtained after stirring, it includes 6% sucrose, 1.5% glucose, and 0.25% soybean Peptid...

Embodiment 3

[0053] (1) Preparation of pea milk base material: weigh 800g of dry peas, put the peas in boiling water for 20 minutes, soak for 15 minutes to achieve the effect of inactivating enzymes; adopt wet method for shelling after soaking; Take 0.07mol / L citric acid solution and soak for 6 hours according to the mass ratio of beans:water of 1:6, wash with water for 3 hours under stirring, change the water every 1 hour, and take out the beans; The water ratio was beaten for 2 minutes, the pH was adjusted to 8.5 with NaOH and maintained for 30 minutes, centrifuged at 5000g for 15 minutes, and the supernatant was taken to obtain the pea milk base material with a reduced beany smell;

[0054] (2) Ingredients: adjust the above-mentioned pea milk base material with water to a protein concentration of 3.0%, and mix the ingredients and fully stir for 10 minutes; based on the final solution obtained after stirring, it includes 6% sucrose, 1.2% glucose, 0.2% soybean peptide, 0.1% disodium hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com