Making method of sturgeon cartilage sauce mixed with rice

A technology of cartilage bibimbap sauce and production method, applied in food science and other directions, can solve the problems of long softening time, long processing period, single taste, etc., to increase aroma and natural flavor, improve color and brightness, save time and energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

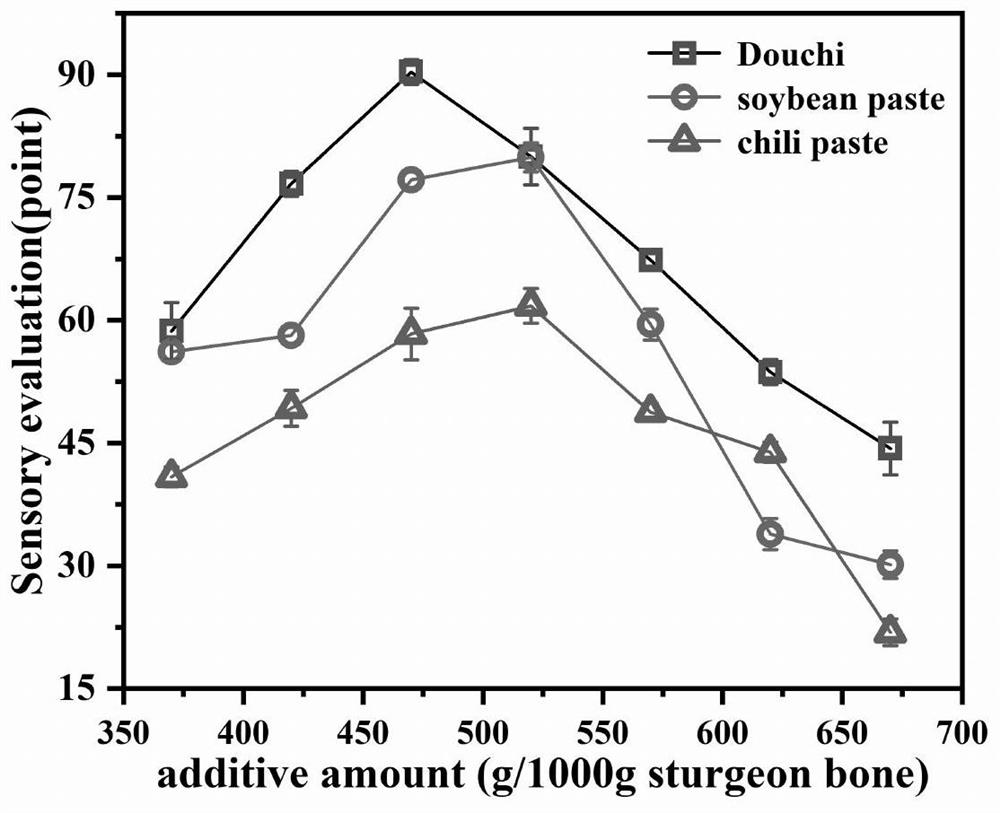

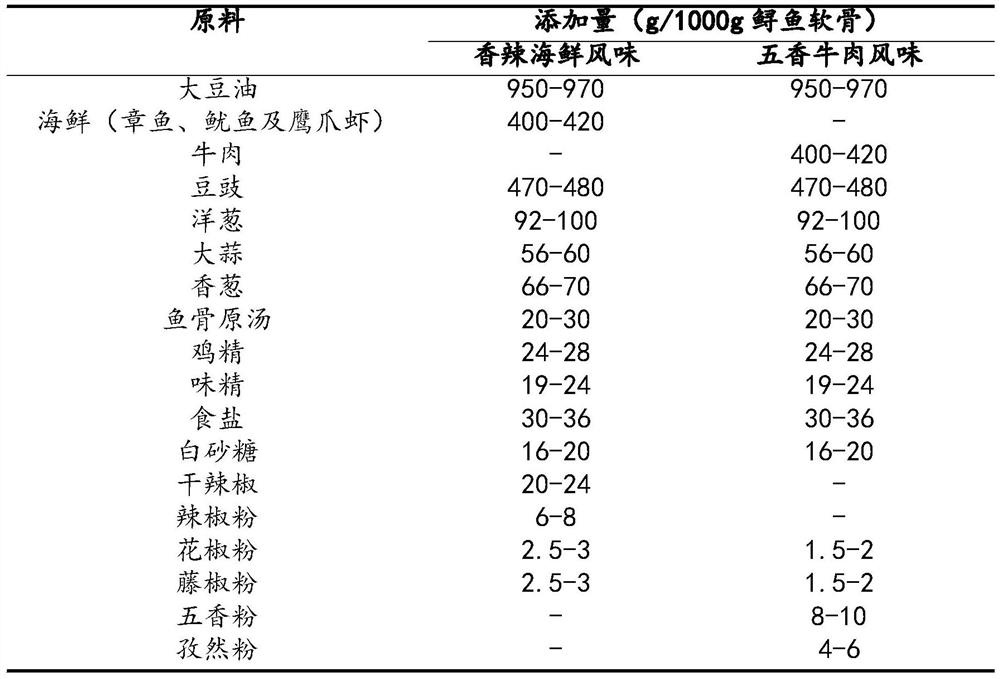

[0049] A preparation method of spicy seafood flavor sturgeon cartilage bibimbap sauce, the formula composition is as follows in Table 3:

[0050] table 3

[0051]

[0052] The method includes the following steps:

[0053] (1) Sturgeon cartilage pretreatment:

[0054] a. Add compound protease with 0.6% of head weight to the cleaned sturgeon head, and soak in warm water at 50-55°C for 15 minutes; the weight ratio of compound protease is: papain: flavor protease: bromelain: ginger protease=2 :1:1:1;

[0055] b. Add 0.1% lipase to the cleaned sturgeon spine by weight, and soak in warm water at 35°C-40°C for 15 minutes;

[0056] c. After soaking, remove the remaining meat on the spine of the sturgeon, the hard bone on the surface of the fish head and the fish meat; take out the cartilage, cook at 40kPa (absolute pressure is 141325Pa) for 25min to soften the fish bones, filter and cut into cubes. Sturgeon cartilage diced, set aside;

[0057] (2) Preparation of fish bone brot...

Embodiment 2

[0073] A preparation method of sturgeon cartilage bibimbap sauce, the recipe composition and preparation method are the same as those in Example 1, except that fermented soya bean sauce is used instead of soybean paste.

Embodiment 3

[0075] A preparation method of sturgeon cartilage bibimbap sauce, the formula composition and preparation method are the same as in Example 1, the difference is that the tempeh is replaced by chili sauce.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com