Edible amino acid enzyme and preparation method thereof

An amino acid and enzyme technology, applied in the field of bioengineering, can solve the problems of various product types, low product quality, and large number of enterprises, and achieve the effect of enhancing disease resistance, improving immunity, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

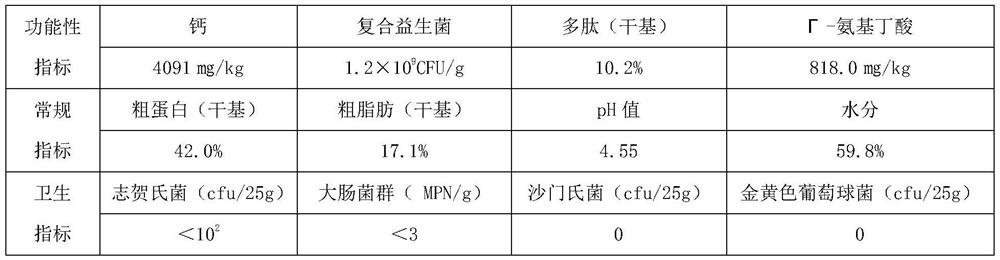

Embodiment 1

[0044] An edible functional amino acid enzyme is made of the following components by weight:

[0045] Component 1: 50 parts of chicken, 30 parts of pork bones, 6 parts of glucose, 2 parts of auxiliary materials (1 part of cornmeal, 1 part of cassava flour), 0.5 parts of compound enzyme preparation (the weight ratio of acid protease and lipase is 3:1) , 0.1 part of fermentation agent A (the weight ratio of Bacillus subtilis, Bacillus licheniformis and Saccharomyces cerevisiae is 1:2:10) and 1 part of fermentation agent B (Enterococcus faecalis, 0.1-2 parts of Lactobacillus plantarum, 0.1 ~0.5 parts of Lactobacillus acidophilus and 0.1~1 part of Streptococcus thermophilus in a weight ratio of 1:10:3:5); component 2: 10 parts of flavoring agent (wherein the weight part is 3 parts of sodium chloride , cooking wine 2 parts, sesame oil 2 parts, honey 1 part, cinnamon paste 1 part and rose flower 1 part).

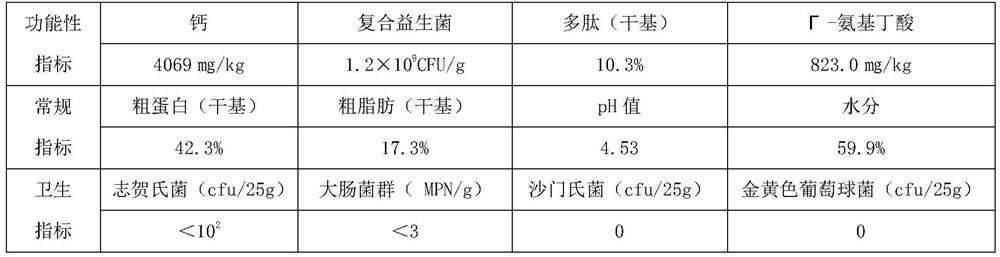

Embodiment 2

[0047] An edible functional amino acid enzyme is made of the following components by weight:

[0048] Component 1: 80 parts of chicken, 20 parts of pork bone, 4 parts of glucose, 0 part of auxiliary materials, 0.1 part of compound enzyme preparation (the weight ratio of acid protease and lipase is 2:1), 0.5 part of fermentation agent A (Bacillus subtilis Bacillus, Bacillus licheniformis and Saccharomyces cerevisiae weight ratio is 1:3:15) and 0.1 part of fermentation agent B (the weight ratio of Enterococcus faecalis, Lactobacillus plantarum, Lactobacillus acidophilus and Streptococcus thermophilus is 1: 15:5:10); component 2: flavoring agent 0 parts.

Embodiment 3

[0050] An edible functional amino acid enzyme is made of the following components in parts by weight: it is made of the following components in parts by weight:

[0051] Component 1: 70 parts of chicken, 25 parts of pork bone, 5 parts of glucose, 1 part of auxiliary material, 0.2 part of compound enzyme preparation (the weight ratio of acid protease and lipase is 1:1), 0.1 part of fermentation agent A (Bacillus subtilis Bacillus, Bacillus licheniformis and Saccharomyces cerevisiae weight ratio is 3:7:10) and 0.1 part of fermentation agent B (the weight ratio of Enterococcus faecalis, Lactobacillus plantarum, Lactobacillus acidophilus and Streptococcus thermophilus is 5: 10:3:5); component 2: 3 parts of flavoring agent (honey).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com