Rectification device for electronic-grade sulfur hexafluoride and control method thereof

A technology of sulfur hexafluoride and control methods, applied in chemical instruments and methods, distillation adjustment/control, separation methods, etc., can solve the problems of less or more impurities, affecting production, reducing economic benefits, etc., and achieve steam output The effect of volume increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

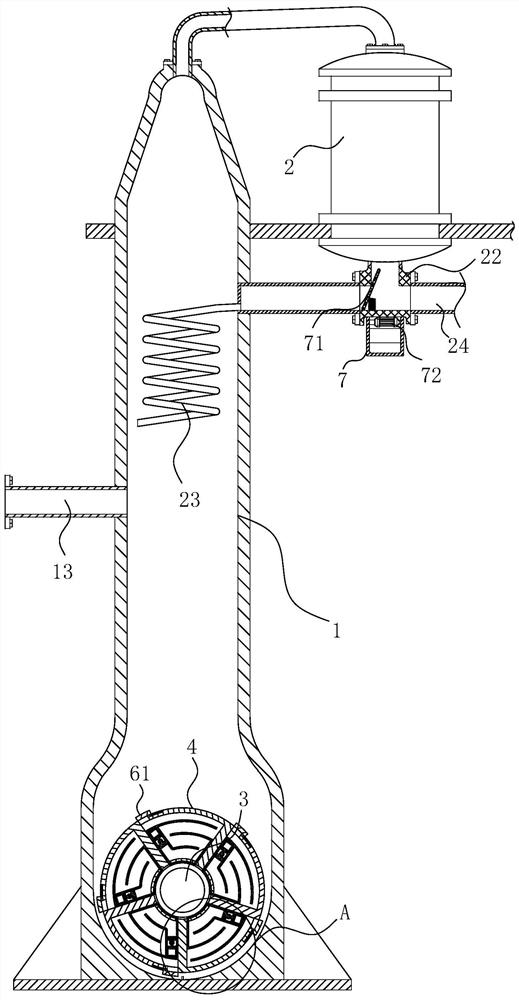

[0040] As an embodiment of the present invention, the reflux pipe 23 is located inside the primary rectification tower 1 and the secondary rectification tower 11 and is in a spiral shape, and the reflux liquid in the reflux pipe 23 promotes the rotation of the separation wheel 4 ;

[0041] During work, the liquid condensed in the first condenser 2 and the second condenser 21 is refluxed in the primary rectification column 1 and the secondary rectification column 11 along the reflux pipe 23, and there is a gap between the refluxed liquid and the rising gas. Heat exchange, and then condense the substance with higher boiling point, and then effectively purify the output steam. The design of the spiral return pipe 23 effectively expands the contact range between the returning liquid and the steam flow, and makes the condensation effect more effective. Well, at the same time, the liquid condensed on the outer wall of the return pipe 23 and the liquid in the return pipe 23 are guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com