Folded plate type demister for treating flue gas desulfurization waste gas

A technology for mist eliminators and waste gas, which is applied in gas treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of huge water resource consumption and limited mist cleaning effect, so as to improve cleaning efficiency, save water consumption, High cleanliness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

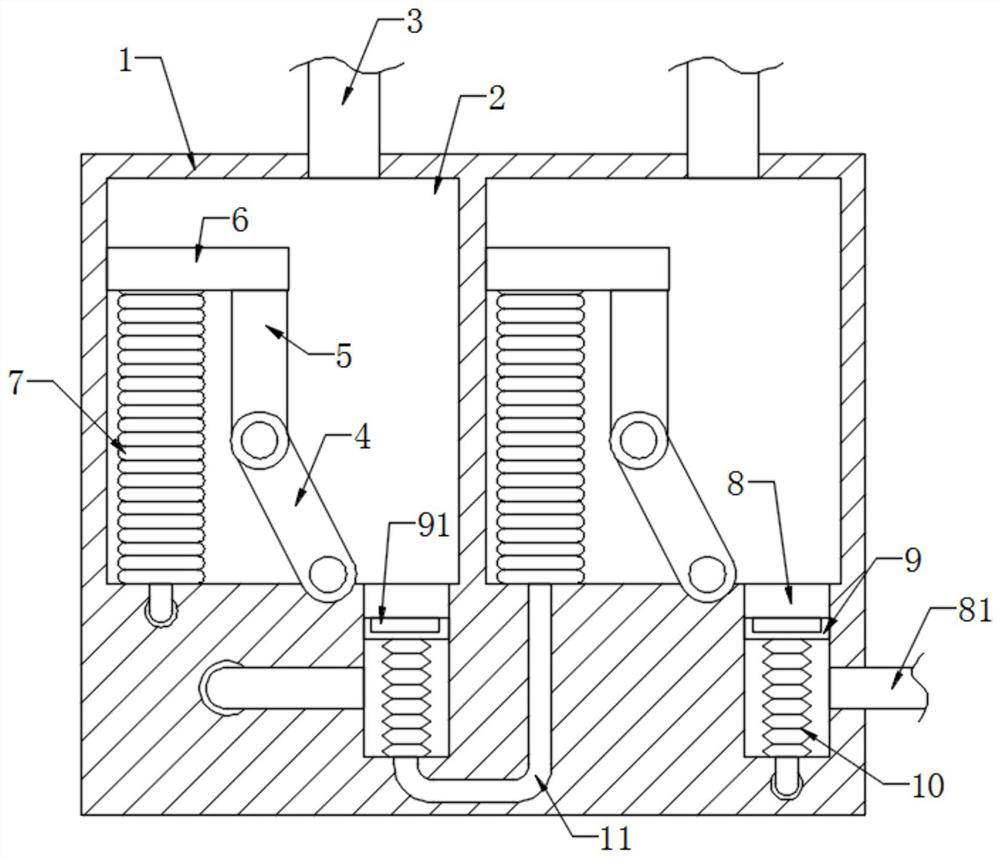

[0023] refer to figure 1 , a folding-plate demister for treating flue gas desulfurization waste gas, comprising a protective shell 1, two defogging chambers 2 are provided on the side wall of the protective shell 1, and an air intake pipe 3 is provided on the inner top of the demistering chamber 2, The inner bottom of the demister chamber 2 is rotatably connected with a first separation plate 4, the upper end of the first separation plate 4 is rotatably connected with a second separation plate 5, and the upper end of the second separation plate 5 is fixedly connected with a support plate 6. It should be noted that , the support plate 6 is slidably connected to the inner wall of the demisting chamber 2, and a chute 8 is provided at the bottom of the demisting chamber 2, and a driving device for driving the support plate 6 to move up and down is installed in the chute 8, and the sealing sliding connection in the chute 8 There is a slide plug 9, the upper end of the slide plug 9 ...

Embodiment 2

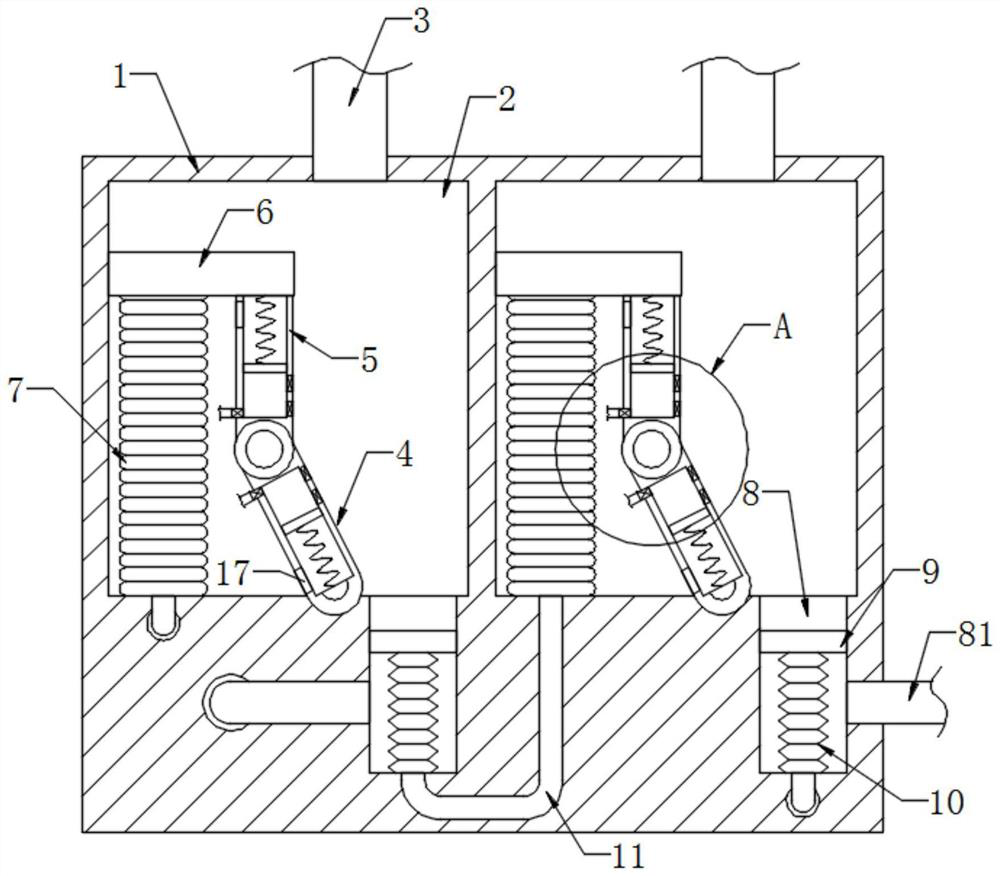

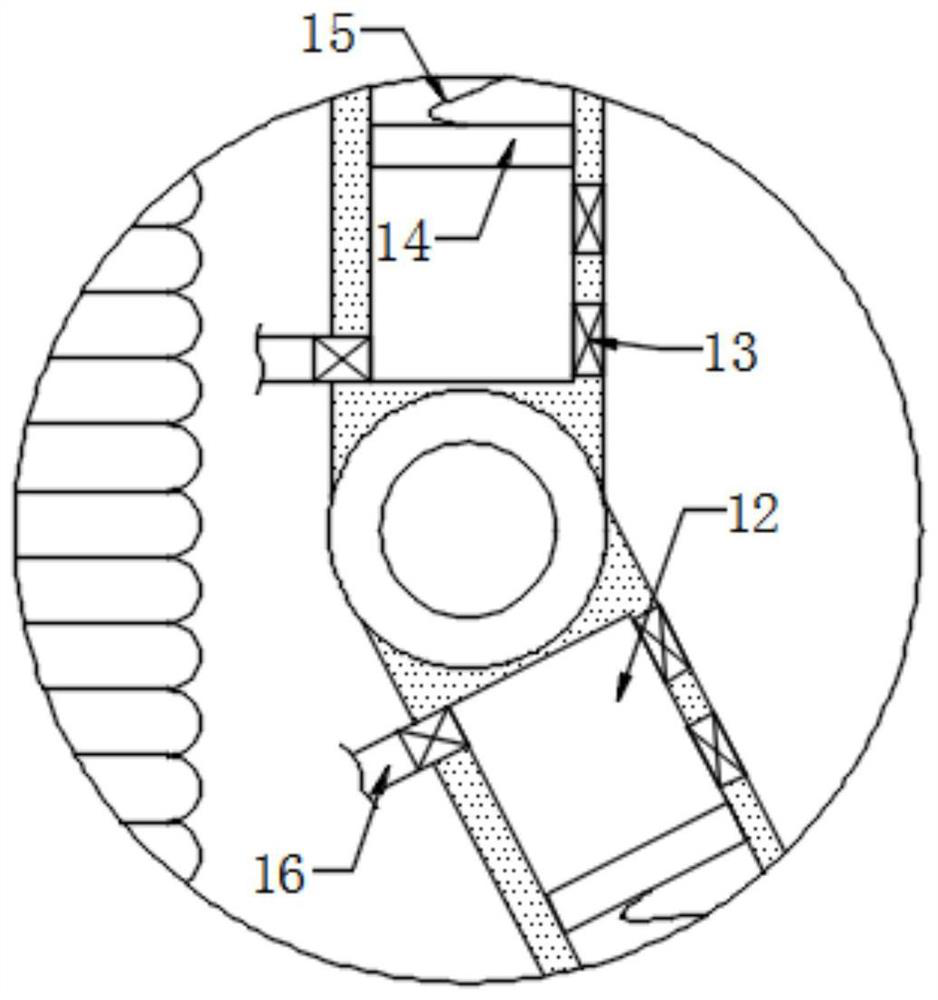

[0030] refer to Figure 2-3 , different from Embodiment 1, the sidewalls of the first separation plate 4 and the second separation plate 5 all start to have an air suction groove 12, and a magnetic piston 14 is sealed and slidably connected in the air suction groove 12, and the two magnetic pistons The opposite magnetic poles of the piston 14 are opposite, and the magnetic piston 14 is elastically connected to the inner wall of the air suction groove 12 through the spring 15, and a plurality of one-way air inlet holes 13 are provided on the inner wall of the air suction groove 12.

[0031] A one-way air outlet pipe 16 is provided on the inner wall of the suction groove 12, and a plurality of one-way air inlet holes 13 are all close to the rotational connection of the first separation plate 4 and the second separation plate 5, and the air outlet end of the one-way air outlet pipe 16 is arranged on In addition to the mist chamber 2, the one-way air inlet 13 only allows air to fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com