Method for measuring shrinkage rate of injection molding product by using three-dimensional digital image technology

An image technology, three-dimensional digital technology, applied in the field of injection molding, can solve problems such as the amount of deformation of objects that cannot be characterized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

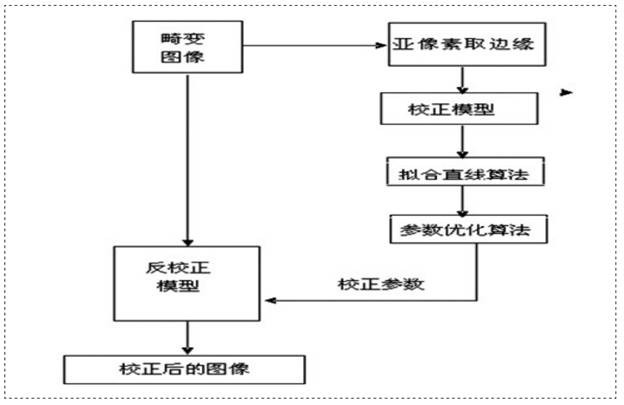

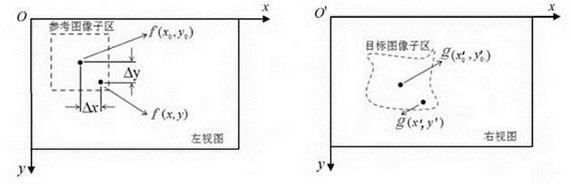

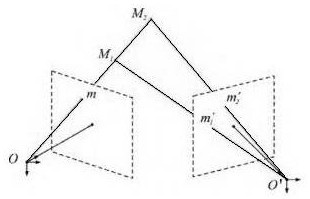

[0034] A method for measuring the shrinkage rate of injection molded products using three-dimensional digital image technology, such as Figure 1~3 shown, including the following steps:

[0035] (1) Fix the optical path: fix two CCD cameras, adjust the angle between the two CCD cameras, fix the light source, make the measured area in the visualized mold cavity evenly illuminated, open the digital image measurement software system, and compare the collected image area on the screen To adjust the aperture and focus of the CCD camera to ensure that the speckle in the measured area captured is clear and the size is appropriate; and the optical path is calibrated to establish a virtual coordinate system in space to determine the three-dimensional geometric position of a point on the surface of a space object and the point in the The relationship between corresponding points in the image, that is, the geometric model of camera imaging is established by calibrating the optical path, ...

Embodiment 2

[0050] The difference between this example and Example 1 is that the amount of silicon carbide black particles added is different, and the amount of silicon carbide added in this example is 1 / 10,000 of the total mass of the melt.

Embodiment 3

[0052] The difference between this embodiment and Embodiment 1 is that the amount of silicon carbide black particles added is different, and the amount of silicon carbide added in this embodiment is 1 / 5000 of the total mass of the melt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com