A kind of preparation method of sea salt disinfectant

A disinfectant and sea salt technology, applied in the direction of disinfectants, botany equipment and methods, chemical instruments and methods, etc., can solve the problems of skin irritation, bactericidal ability is not as good as 84 disinfectant, ethanol is flammable and explosive, and achieves good skin care and nutritional efficacy, the production process is green and environmentally friendly, and the effect of good sterilization and protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation and application method of 50ml bottled spray fungicide

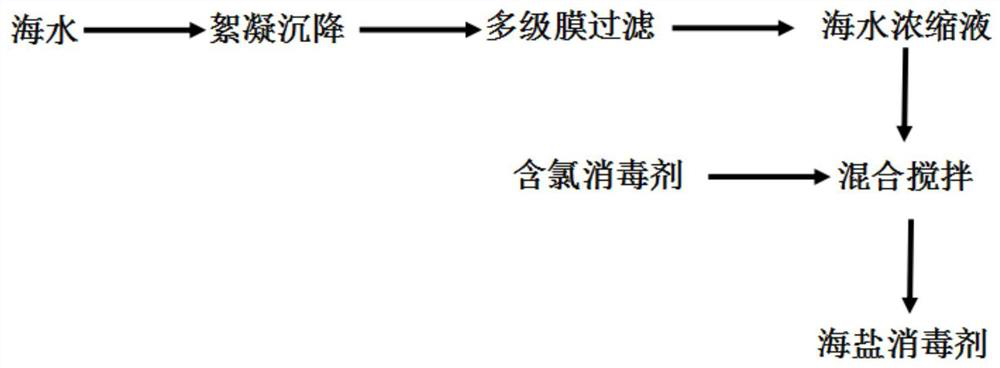

[0032] Using seawater as raw material, advanced flocculation and sedimentation tanks are used for flocculation and sedimentation, and then filtered by activated carbon to remove flocs and heavy metals in raw seawater. After purification, the NTU of seawater is 0.5, and the content of heavy metal Pb is 10mg / Kg, which meets GB14930.2-2012 (National Food Safety Standard—Disinfectant); The purified solution is separated by nanofiltration membrane, and the concentrated solution after separation is diluted with water, and then nanofiltration is performed again, and the concentrated solution filtered by the nanofiltration membrane for the last time is kept for control. The conductivity of the retentate is 200ms / μs. At this time, sodium hypochlorite solution (available chlorine is 10%) is added to the retentate of the nanofiltration membrane, and 1.5g of sodium hypochlorite solution is added to each 1L of the r...

Embodiment 2

[0043] Preparation and application method of 500ml bottled spray fungicide

[0044] Using brine as raw material, the raw brine is flocculated, precipitated and filtered with activated carbon to remove flocs and heavy metals in the raw water. After purification, the NTU of the liquid is 0.8, and the heavy metal content meets the requirements of GB 14930.2-2012 (National Food Safety Standard - Disinfectant); The purified solution is then separated by nanofiltration membrane, and the concentrated solution after separation is diluted with water, and then nanofiltration is performed again, and the concentrated solution filtered by the nanofiltration membrane for the last time is kept, and the conductivity of the retentate is controlled to be 260ms / μs. Add chloramine T (available chlorine is 20%) in the nanofiltration membrane retentate, add 1g chloramine T in every 1L of retentate, mix evenly after stirring, fill into 500ml / bottle disinfectant product.

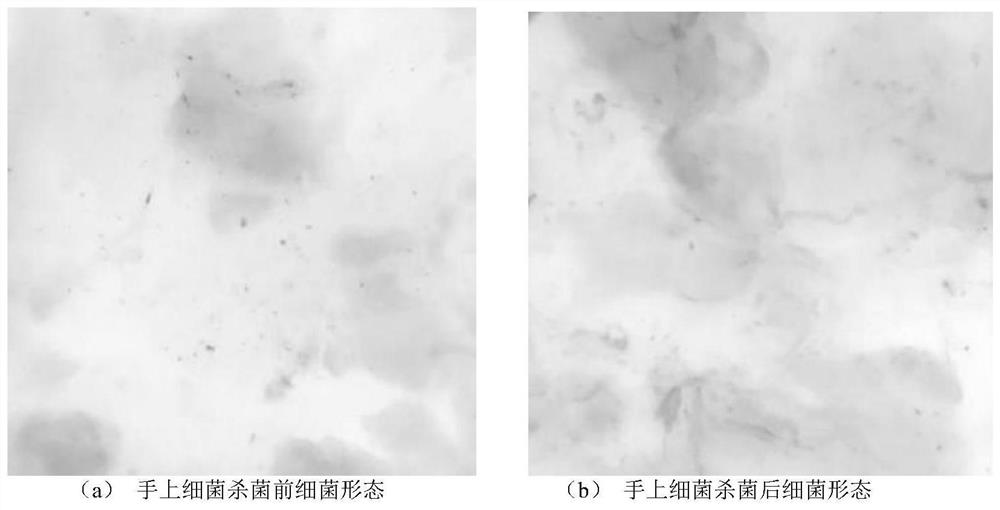

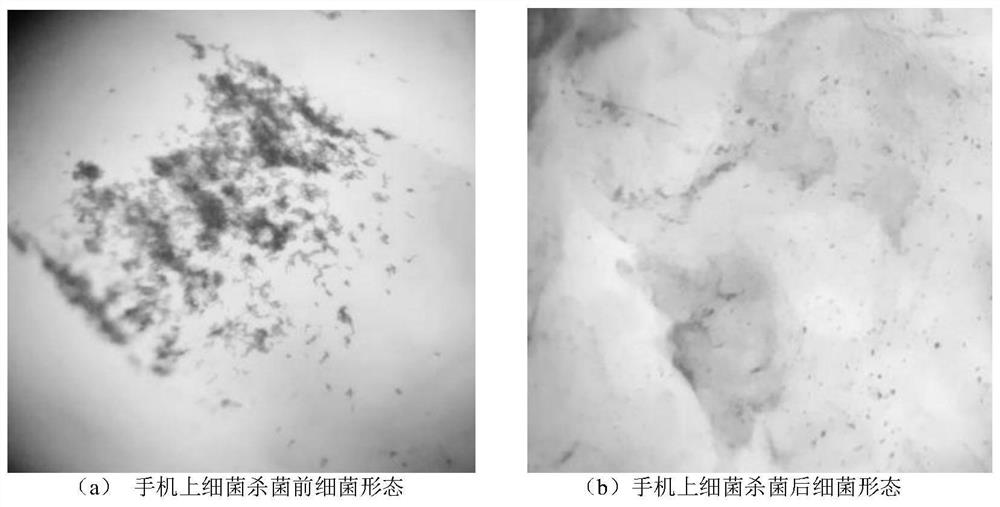

[0045]Utilize the spray dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com