Active control method for uniform distribution and growth direction of reinforcing phase in particle reinforced titanium-based composite material

A titanium-based composite material and particle reinforcement technology, applied in additive processing, additive manufacturing, etc., can solve the problems of limited precision and size of components, caving and pores, and high defect rate, and achieve improved mechanical properties, wide range of applications, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

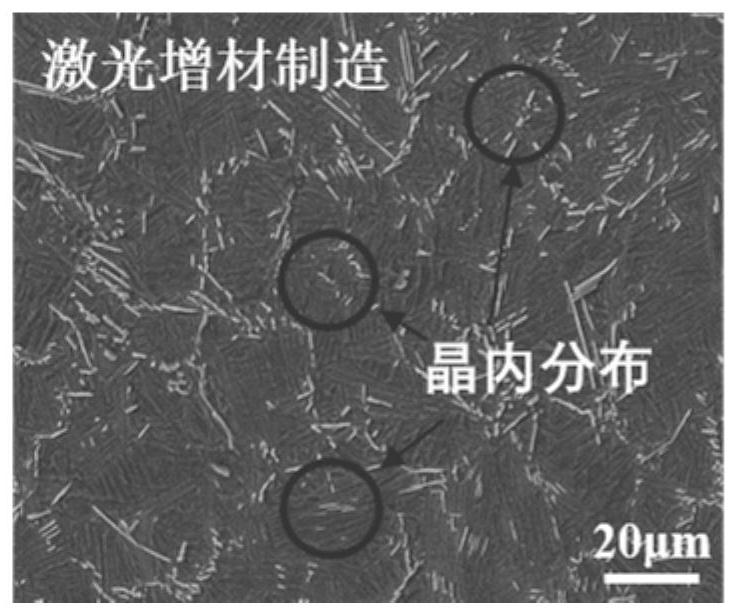

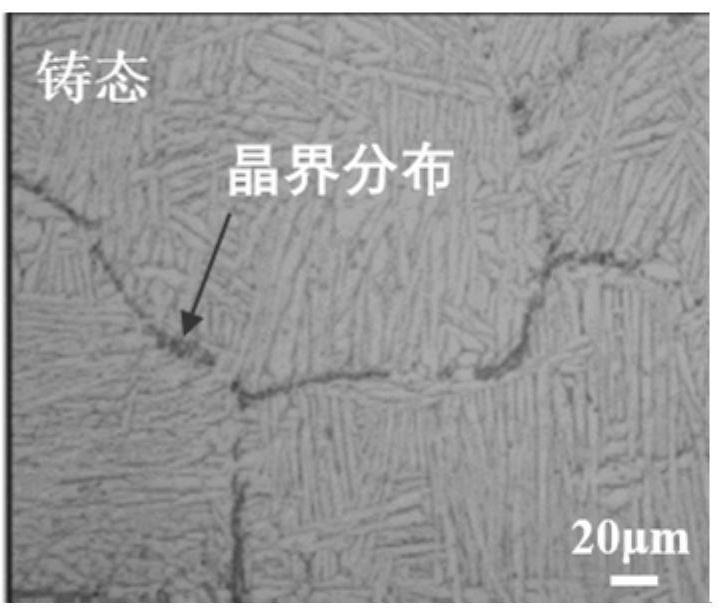

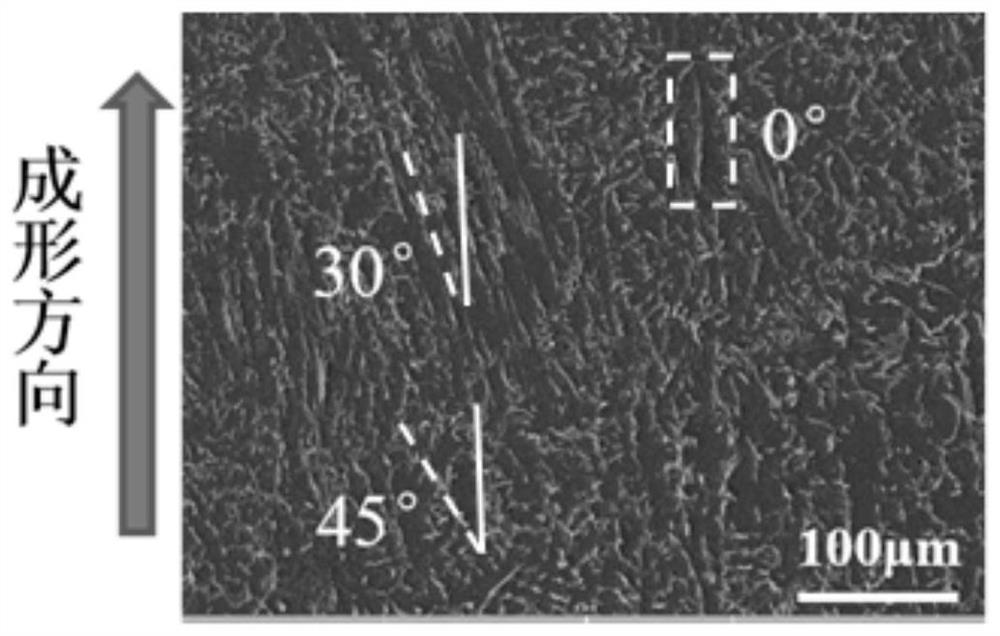

[0032] In this embodiment, the uniform distribution of the reinforcement phase and the active control method of the growth direction in the particle-reinforced TC4-0.05B titanium-based composite material include the following steps:

[0033] (1) Base material preparation: The base material is the substrate used in the laser additive manufacturing process, and its composition is Ti-6Al-4V (wt.%), which is used to prevent the high temperature in the laser additive manufacturing process from causing the formation of the formed component. deformation;

[0034] (2) Forming material preparation: The forming material adopts TC4-0.05B titanium-based composite material pre-alloyed powder, the powder particle size is 15-53 μm, its composition is Ti-6Al-4V-0.05B (wt.%), and the oxygen content is lower than 0.2wt.%;

[0035] (3) Forming process: The forming sample is prepared by laser additive manufacturing. The main process parameters in the forming process are: laser power 130W, ...

Embodiment 2

[0039] In this embodiment, the uniform distribution of the reinforcement phase and the active control method of the growth direction in the particle-reinforced TC4-0.5B titanium-based composite material include the following steps:

[0040] (1) Base material preparation: The base material is the substrate used in the laser additive manufacturing process, and its composition is Ti-6Al-4V (wt.%), which is used to prevent the high temperature in the laser additive manufacturing process from causing the formation of the formed component. deformation;

[0041] (2) Forming material preparation: The forming material adopts TC4-0.5B titanium-based composite material pre-alloyed powder, the powder particle size is 15-53 μm, its composition is Ti-6Al-4V-0.5B (wt.%), and the oxygen content is lower than 0.2wt.%;

[0042] (3) Forming process: The forming sample is prepared by laser additive manufacturing. The main process parameters in the forming process are: laser power 220W, scanning ...

Embodiment 3

[0046] In this embodiment, the uniform distribution of the reinforcement phase and the active control method of the growth direction in the particle-reinforced TC4-1B titanium-based composite material include the following steps:

[0047] (1) Base material preparation: The base material is the substrate used in the laser additive manufacturing process, and its composition is Ti-6Al-4V (wt.%), which is used to prevent the high temperature in the laser additive manufacturing process from causing the formation of the formed component. deformation;

[0048] (2) Forming material preparation: the forming material adopts TC4-1B titanium-based composite material pre-alloyed powder, the powder particle size is 15-53 μm, its composition is Ti-6Al-4V-1B (wt.%), and the oxygen content is lower than 0.2wt .%;

[0049] (3) Forming process: The formed sample is prepared by laser additive manufacturing. The main process parameters in the forming process are: laser power 250W, scanning rate 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com